Removable rapid waste water treatment equipment

A technology for wastewater treatment and equipment, which is applied in the field of integrated movable rapid treatment devices to achieve high-efficiency treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

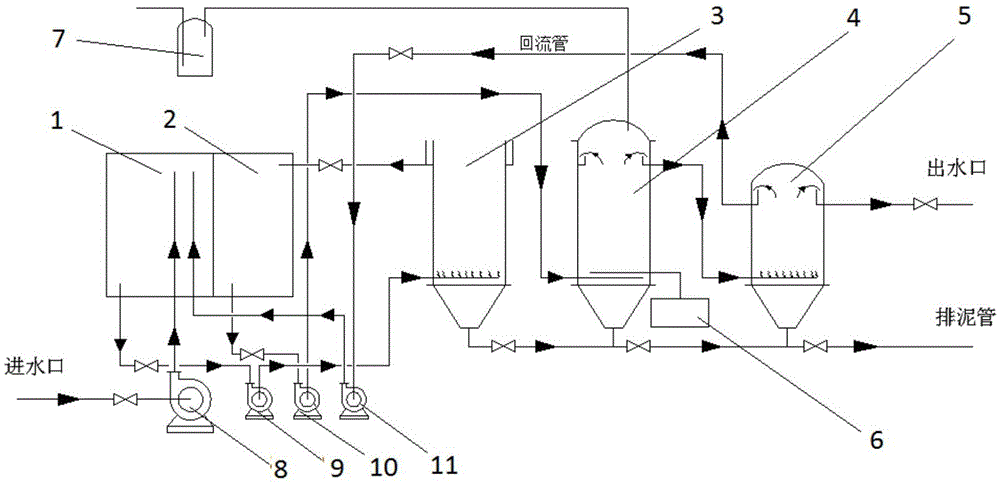

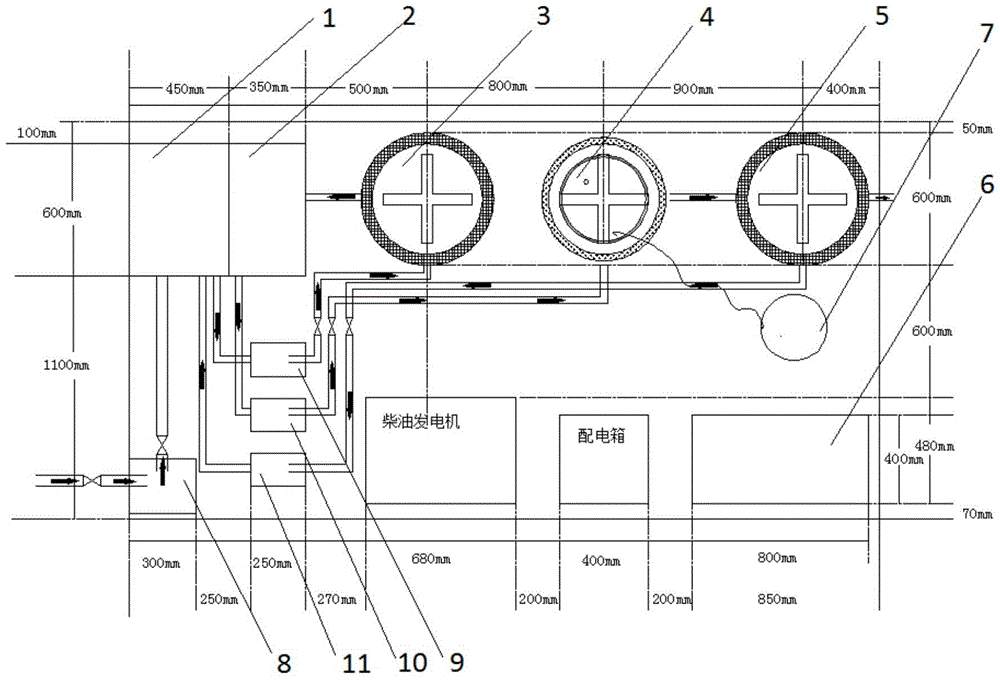

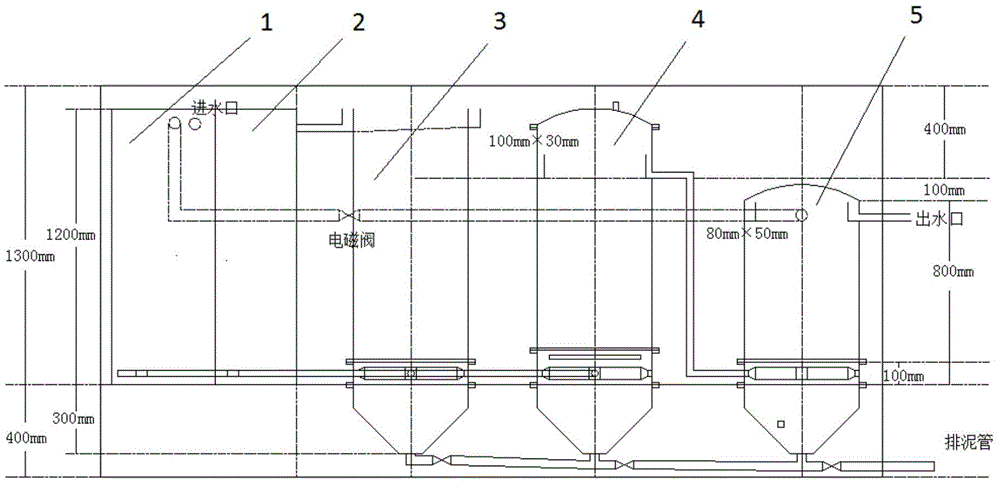

[0025] Embodiment 1 specifically describes the overall composition and wastewater treatment process of the mobile rapid wastewater treatment equipment of the present invention in conjunction with the accompanying drawings.

[0026] Figure 1~3 A schematic diagram of the overall composition of the mobile rapid wastewater treatment equipment is given. In the figure, 1 is the regulating pool, 2 is the intermediate pool, 3 is the micro-electrolysis reaction column, the micro-electrolysis reaction column 3 is added with the applicant’s self-made regularized micro-electrolysis packing, 4 is the ozone catalytic oxidation reaction column, and the ozone catalytic oxidation reaction column 4 Add the applicant's self-made silica gel carrier catalyst loaded with iron and manganese in advance, 5 is the activated carbon adsorption column, 6 is the ozone generator, 7 is the ozone adsorption tank, 8 is the waste water inlet pump, 9 is the micro electrolysis reaction column inlet pump, 10 is t...

Embodiment 2

[0031] The making of embodiment 2 regularized micro-electrolysis packing

[0032] The regularized micro-electrolysis packing added in the micro-electrolysis reaction column 3 is self-made in the laboratory. The production of structured micro-electrolytic fillers is to mix iron filings, manganese powder, activated carbon powder and clay at a mass ratio of 5:0.7:1:3.3, add a small amount of deionized water as a binder, and shake the mixture into granules , when the particle size of the filler reaches 3-10mm, put the filler in an oven and dry at 50°C for 2 hours. After drying, spread a layer of fine sand on the surface of the filler to isolate the air and prevent oxidation, then put it into a muffle furnace and heat and roast at 300°C for 3 hours, and then the regular micro-electrolytic filler is obtained after cooling.

[0033] According to the results of laboratory simulation experiments, the regularized micro-electrolysis filler of the present invention can remove more than 7...

Embodiment 3

[0034] Preparation of the silica gel carrier catalyst of embodiment 3 loaded iron and manganese

[0035]In the ozone catalytic oxidation reaction column 4, add in advance the laboratory-made silica gel carrier loaded with iron and manganese as a catalyst. The preparation process of the new catalyst is as follows: first, the carrier silica gel purchased is cleaned, and after drying, the carrier silica gel is immersed in the first In the 10% nitrate solution in which the mass ratio of dissolved Mn and Fe is 3:1, 1.20Kg of carrier silica gel and 2.5L of nitrate solution have been weighed, and then immersed at 40°C for at least 24h. Take it out and drain it, then put it in an oven at 85°C and bake it for about 8 hours, take it out and put it in a muffle furnace, adjust it to 450°C, and bake it for 6 hours. After cooling to room temperature naturally, rinse it with distilled water until almost Until no metal ions are detected, place it in a ventilated place to dry for later use.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com