Method for improving coal bed gas recovery efficiency by electrochemistry

A coalbed methane and electrochemical technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of small gas production range, insignificant production increase effect, poor applicability, etc., and achieve outstanding substantive characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

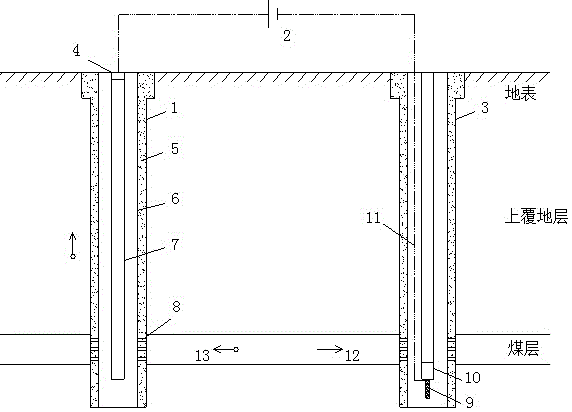

[0023] Implement a method for electrochemically enhancing the recovery of coalbed methane, the method is carried out according to the following steps:

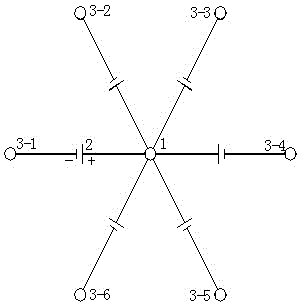

[0024] a) According to geological characteristics and existing construction technology, drill 7 vertical wells, one of which is liquid injection well 1, and the remaining 6 gas production wells 3 are arranged at 60° around the liquid injection well, and the distance between gas production wells is 430m. Install a disc-shaped iron anode electrode 4 with a diameter of 200 mm and a thickness of 300 mm at the head of the injection well, and install a rod-shaped iron cathode electrode 9 with a diameter of 80 mm and a length of 800 mm at the bottom of the gas production well;

[0025] b) Use insulated wires to connect the anode electrode at the wellhead of the injection well and the cathode electrode at the bottom of each gas production well in series respectively, and connect them to the positive or negative pole of the DC power sup...

Embodiment approach 2

[0030] Implement a method for electrochemically enhancing the recovery of coalbed methane, the method is carried out according to the following steps:

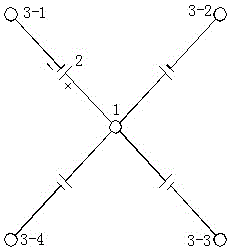

[0031] a) According to geological characteristics and existing construction technology, drill 5 vertical wells, one of which is liquid injection well 1, and the remaining 4 gas production wells 3 are arranged at 90° centered on the liquid injection well, and the distance between gas production wells is 370m. Install a disc-shaped copper anode electrode 4 with a diameter of 150 mm and a thickness of 250 mm at the head of the injection well, and install a rod-shaped copper cathode electrode 9 with a diameter of 60 mm and a length of 700 mm at the bottom of the gas production well;

[0032] b) Use insulated wires to connect the anode electrode at the wellhead of the injection well and the cathode electrode at the bottom of each gas production well in series respectively, and connect them to the positive or negative pole of the DC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com