Novel dipolar membrane and use thereof in electrolysis preparation of ferrate

A ferrate and bipolar membrane technology, applied in the field of electrochemistry, can solve the problems of low concentration of sodium ferrate products, complex process, low current efficiency, etc., and achieve the effects of easy promotion, cost reduction, and smooth current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

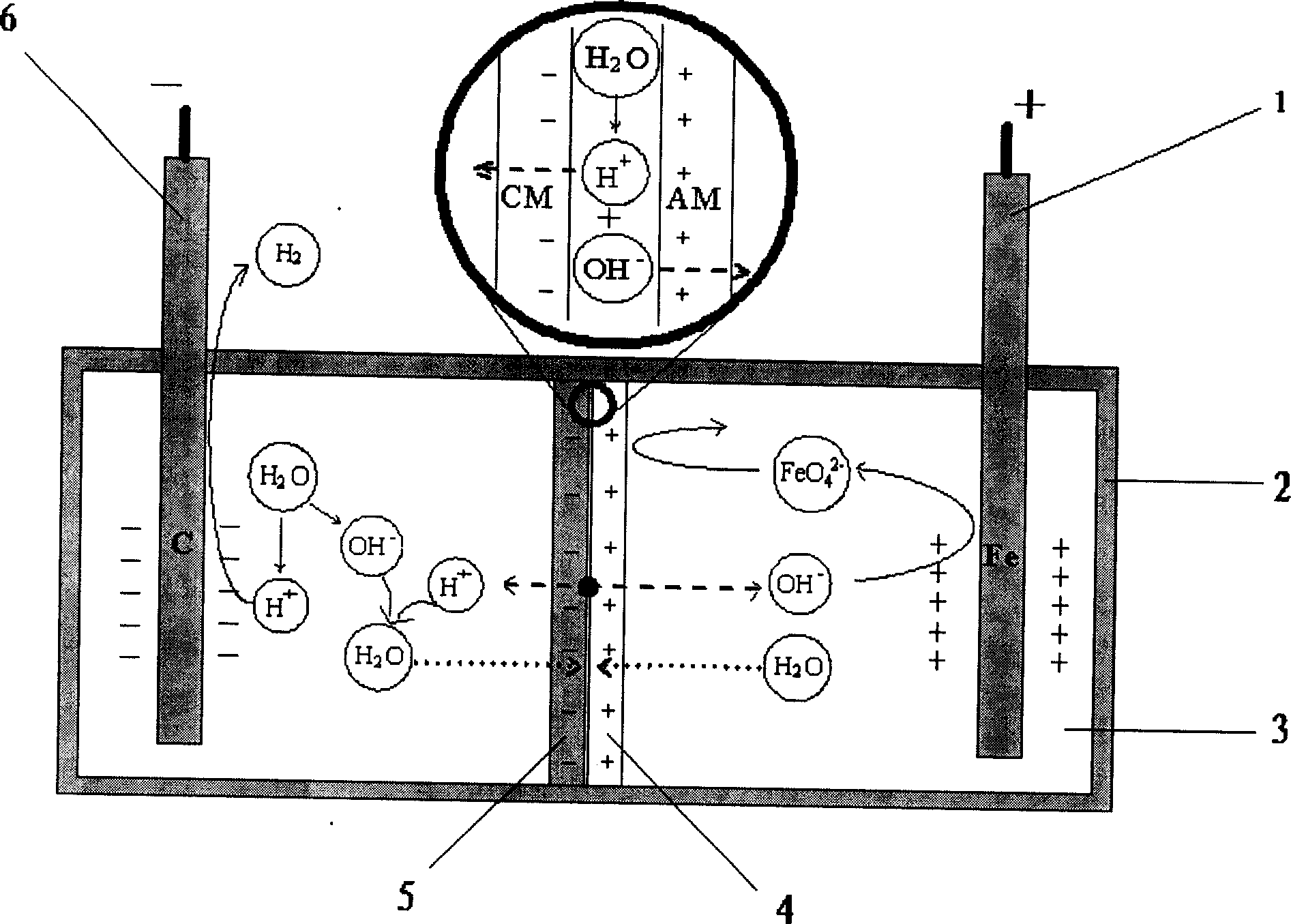

Method used

Image

Examples

Embodiment 1

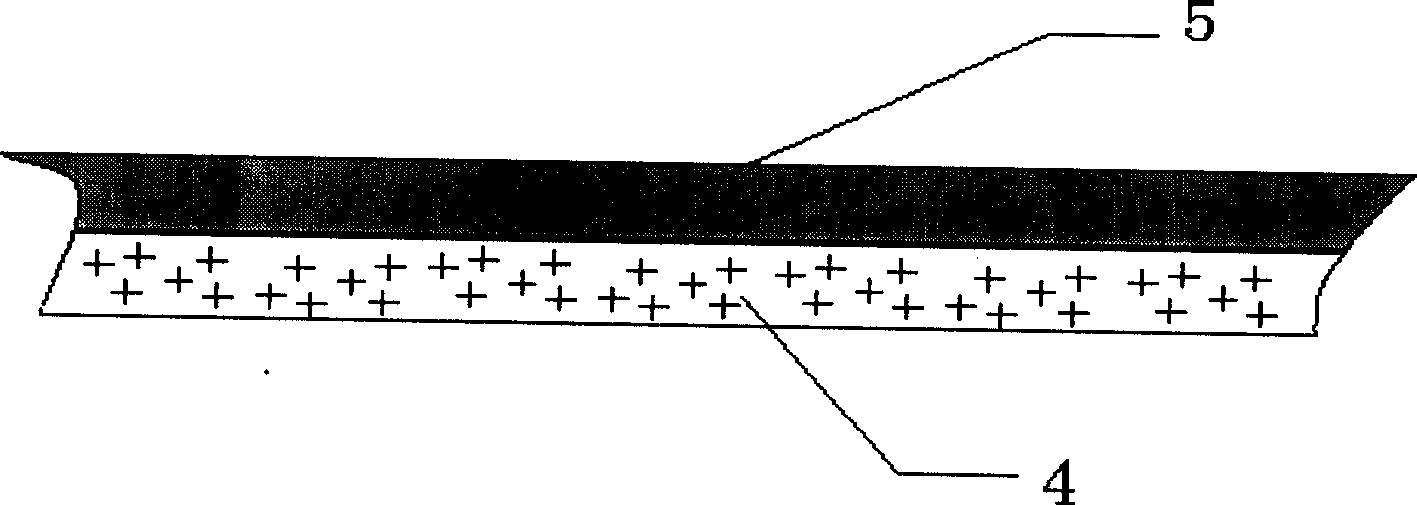

[0028] The preparation of anodic film: take by weighing 3 grams of sodium carboxymethylcellulose in a 500ml beaker, heat on low fire, add distilled water 100ml while stirring, be mixed with the aqueous solution of 3% sodium carboxymethylcellulose (CMC), through After decompression and decolorization into a colorless, transparent and viscous film, cast it on a clean and smooth glass plate; after 24 hours of natural drying to form a film, soak it in 0.5% FeCl 3 In the solution for 8 minutes, take it out and dry it naturally to obtain the anode film.

[0029] The preparation of cathode film: take by weighing 3 grams of chitosan (CS) in a 500ml beaker, stir and dissolve with 2% acetic acid aqueous solution, be mixed with 100ml chitosan acetic acid aqueous solution, slowly add dropwise the glutaraldehyde of 3ml 0.25%, At the same time, the stirring speed was increased, and after being decolorized under reduced pressure into a light yellow viscous film liquid, it was cast on the pre...

Embodiment 2

[0032] The preparation of cathode film: take by weighing 3 grams of sodium carboxymethylcellulose in a 500ml beaker, heat on low heat, add about 100ml of distilled water while stirring, and be mixed with an aqueous solution of 3% sodium carboxymethylcellulose (CMC), After being decolorized under reduced pressure into a colorless, transparent and viscous film, cast it on a clean and smooth glass plate, and after 30 hours of natural drying to form a film, soak it in 0.5% FeCl 3 In the solution for 15 minutes, take it out and dry it naturally to obtain the anode film.

[0033] Preparation of cathode film: take 3 grams of chitosan (CS) in a 500ml beaker, stir and dissolve with 2% acetic acid aqueous solution, prepare 100ml chitosan acetic acid aqueous solution, slowly add 4.5ml 0.25% glutaraldehyde dropwise At the same time, the stirring speed was increased, and after being decolorized under reduced pressure into a light yellow viscous film liquid, it was cast on the pre-prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com