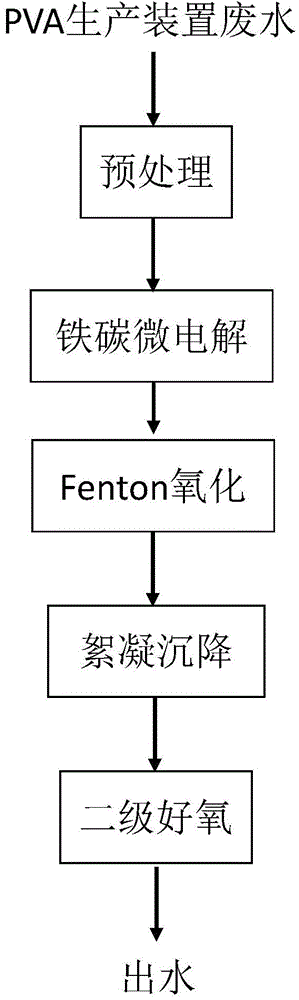

PVA production apparatus wastewater treatment method

A technology of production equipment and treatment method, which is applied in the field of wastewater treatment of PVA production equipment, can solve problems such as failure to meet discharge standards, achieve significant economic and social benefits, simple maintenance, and achieve discharge standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: the PVA production plant waste water of certain enterprise, COD is 1600mg / L, and pH is 7.5, and main pollutant is PVA and acetate, and processing steps are as follows:

[0056] Step 1: pretreatment, adding sulfuric acid to the waste water of the PVA production plant to adjust its pH to 2;

[0057] Step 2: Iron-carbon micro-electrolysis, the above-mentioned pretreated PVA production plant wastewater enters the iron-carbon micro-electrolysis reaction tank, aeration reaction, the gas-water ratio is 6:1, stays for 1h, Fe in the treated PVA production plant wastewater 2+ The concentration is 100mg / L;

[0058] Step 3: Fenton oxidation, the wastewater from the PVA production plant treated by iron-carbon micro-electrolysis enters the Fenton oxidation reaction pool, and H 2 o 2 , the concentration is 1500mg / L, stir to react, and stay for 4h;

[0059] Step 4: Flocculation and sedimentation, add sodium hydroxide to the effluent after Fenton oxidation, adjust the p...

Embodiment 2

[0062] Embodiment 2: the PVA production plant waste water of certain enterprise, COD is 1000mg / L, and pH is 6.5, and main pollutant is PVA and acetate, and processing steps are as follows:

[0063] Step 1: pretreatment, adding sulfuric acid to the waste water of the PVA production plant to adjust its pH to 4;

[0064] Step 2: Iron-carbon micro-electrolysis, the wastewater from the PVA production plant after the above pretreatment enters the iron-carbon micro-electrolysis reaction tank, aeration reaction, the gas-water ratio is 10:1, and stays for 2 hours. After the treatment, Fe in the wastewater from the PVA production plant 2+ The concentration is 300mg / L;

[0065] Step 3: Fenton oxidation, the wastewater from the PVA production plant treated by iron-carbon micro-electrolysis enters the Fenton oxidation reaction pool, and H 2 o 2 , the concentration is 500mg / L, stir to react, and stay for 2h;

[0066] Step 4: flocculation and sedimentation, adding potassium hydroxide to t...

Embodiment 3

[0069] Embodiment 3: the PVA production plant waste water of certain enterprise, COD is 1300mg / L, and pH is 7, and main pollutant is PVA and acetate, and processing steps are as follows:

[0070] Step 1: pretreatment, adding sulfuric acid to the waste water of the PVA production plant to adjust its pH to 3;

[0071] Step 2: Iron-carbon micro-electrolysis, the wastewater from the PVA production plant after the above pretreatment enters the iron-carbon micro-electrolysis reaction tank, aeration reaction, the gas-water ratio is 8:1, and stays for 1.5h. Fe in the wastewater from the PVA production plant after treatment 2+ The concentration is 200mg / L;

[0072] Step 3: Fenton oxidation, the wastewater from the PVA production plant treated by iron-carbon micro-electrolysis enters the Fenton oxidation reaction pool, and H 2 o 2 , the concentration is 1000mg / L, stir to react, and stay for 3h;

[0073] Step 4: Flocculation and sedimentation, add sodium hydroxide to the effluent afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com