Electrolysis treatment process and device for low-content organic pollutants in high-salinity rare earth wet smelting wastewater

A technology of organic pollutants and wet smelting, applied in metallurgical wastewater treatment, water pollutants, water/sewage multi-stage treatment, etc., can solve the problem of easy scaling and corrosion of evaporation equipment, high concentration of organic matter, great environmental hazards, etc. problems, to achieve the effect of thorough oxidation and degradation of organic matter, high treatment efficiency, and no interference from environmental factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

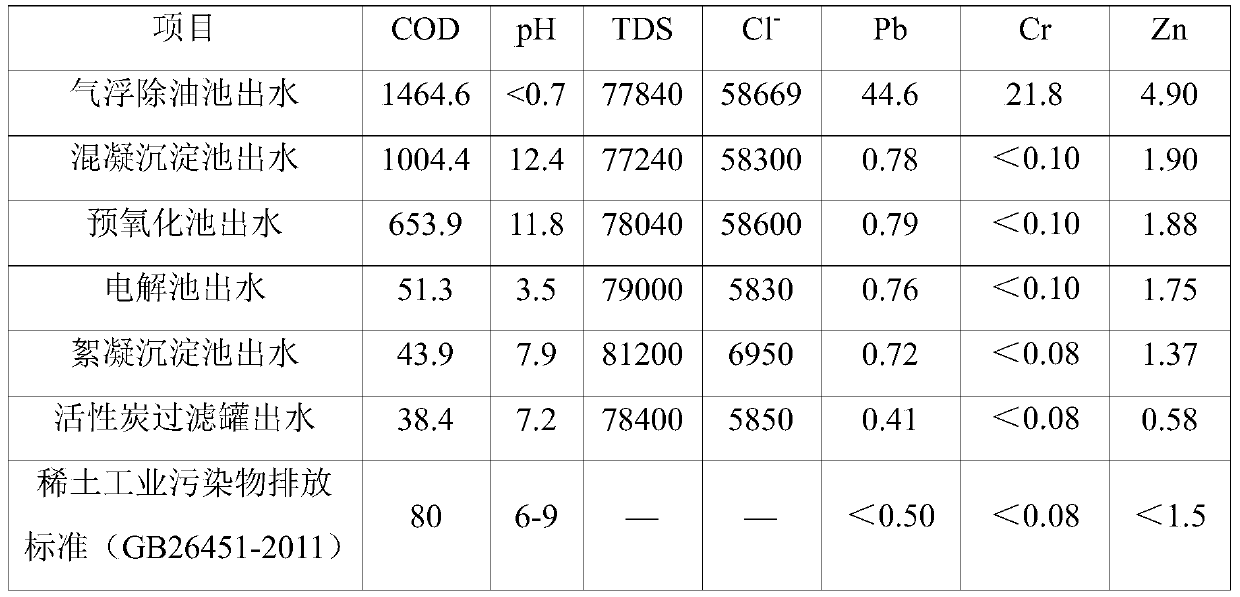

[0069] Taking the organic wastewater produced by the wet smelting extraction process of an ionic rare earth enterprise as the treatment object, the characteristics of the raw water quality of the wastewater are shown in Table 1 below. TDS is the salinity index. Generally, the TDS of tap water in Guangzhou is 60-100mg / L.

[0070] Table 1 Raw water quality of organic wastewater from rare earth hydrometallurgy (mg / L)

[0071] project

COD

pH

TDS

Cl -

Pb

Cr

Zn

2640.8

<0.7

77400

58338

44.4

21.7

4.8

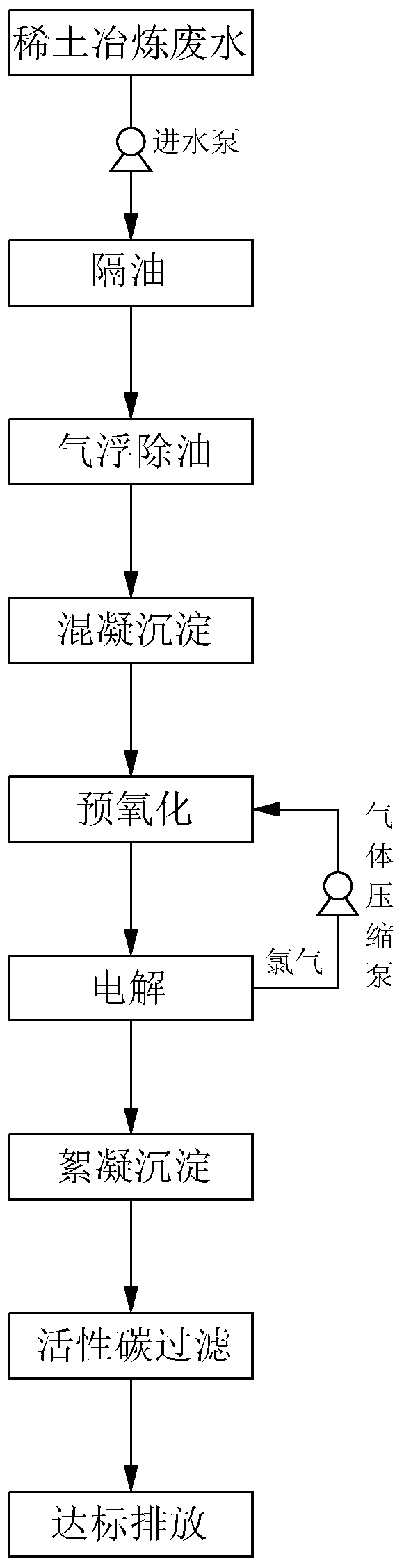

[0072] An electrolytic treatment process for organic pollutants in high-salinity rare earth wet smelting wastewater, the specific treatment process steps are as follows:

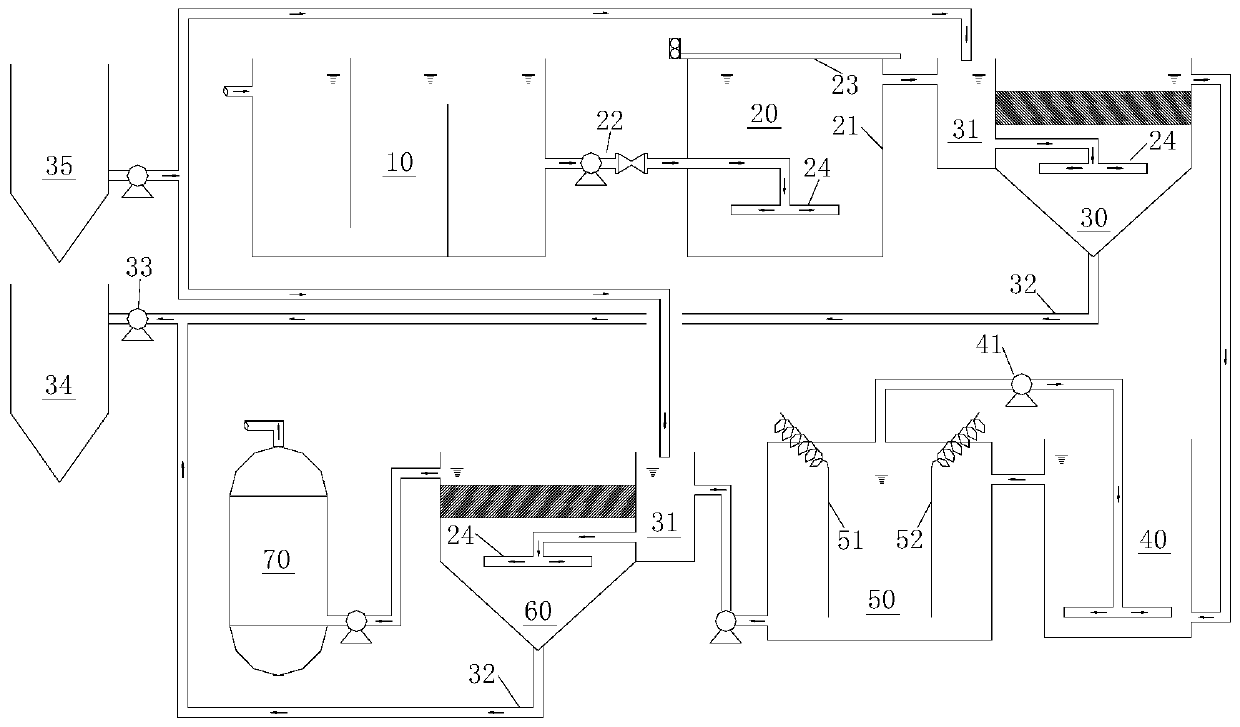

[0073] 1) Start the water inlet pump at a distance of 1m 3 The / h flow rate will drive the organic wastewater of rare earth wet smelting into a volume of 3m 3 The grease trap is used to remove the upper oil slick through the oil s...

Embodiment 2

[0082] Taking the organic wastewater produced by the hydrometallurgy extraction process of an ionic rare earth enterprise as the treatment object, the raw water quality characteristics of the wastewater are shown in Table 3 below.

[0083] Table 3 Raw water quality of rare earth hydrometallurgy organic wastewater (mg / L)

[0084] project

COD

pH

TDS

Cl -

Pb

Cr

Zn

raw water

1986.7

<0.5

128500

92365

27.63

15.45

3.66

[0085] An electrolytic treatment process for organic pollutants in high-salinity rare earth wet smelting wastewater, the specific treatment process steps are as follows:

[0086] 1) Start the water inlet pump at a distance of 10m 3 / h flow rate Rare earth wet smelting organic wastewater into the volume of 30m 3 The oil trap, the upper layer of oil slick is removed by the oil scraper, and then the waste water enters the volume with a volume of 30m 3 The air flotation tank adopts the dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com