Method for slowing electrolysis bath anion and cation thin film laminar flow and device

A film layer, cation technology, applied in the electrolysis process, electrolysis components, chemical instruments and methods, etc., can solve the problems of enlarged electrode plate gap, electrode plate warping and twisting, unsuitable for high flow rate water, etc. The effect of slowing down the flow rate and preventing mixed flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

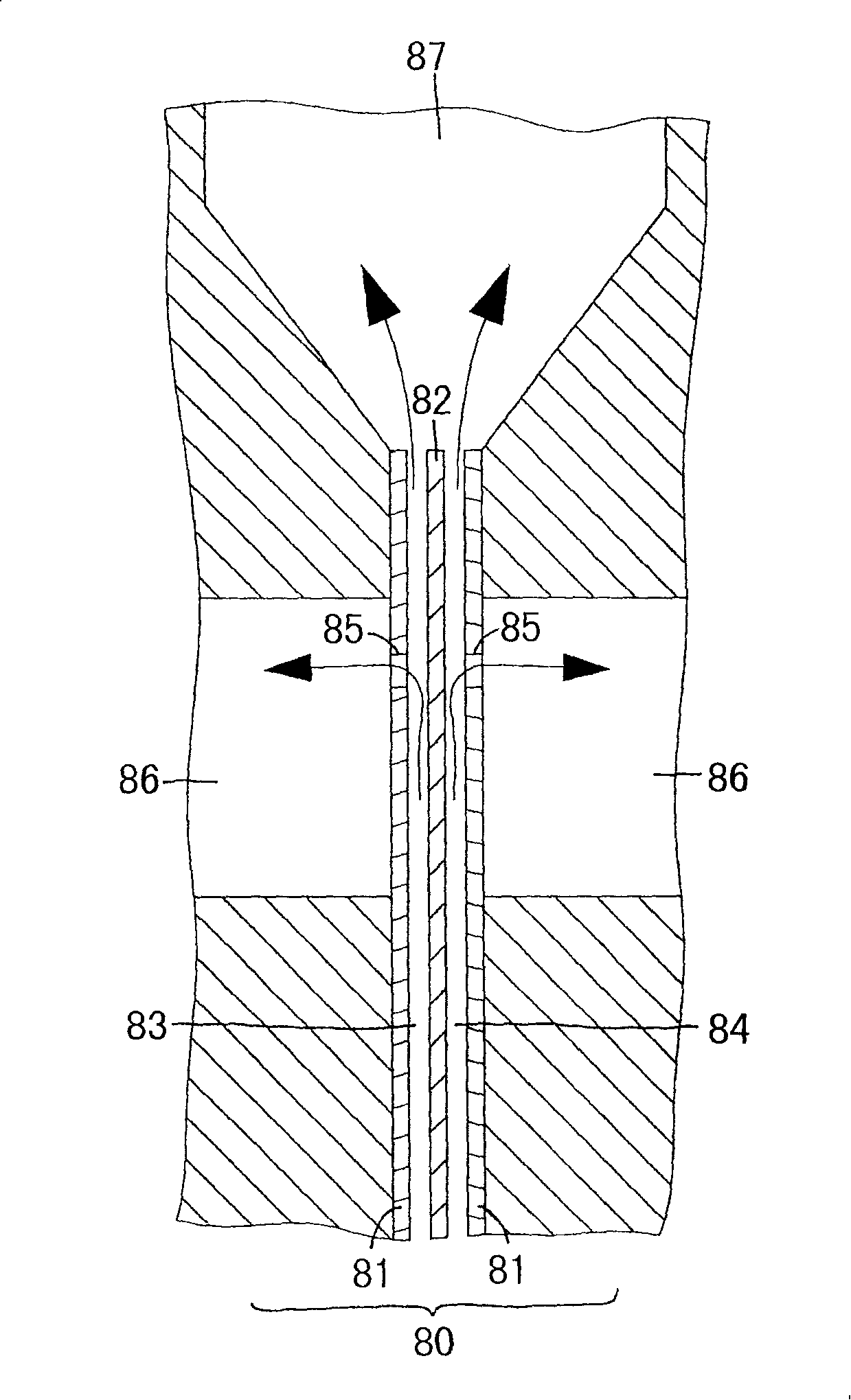

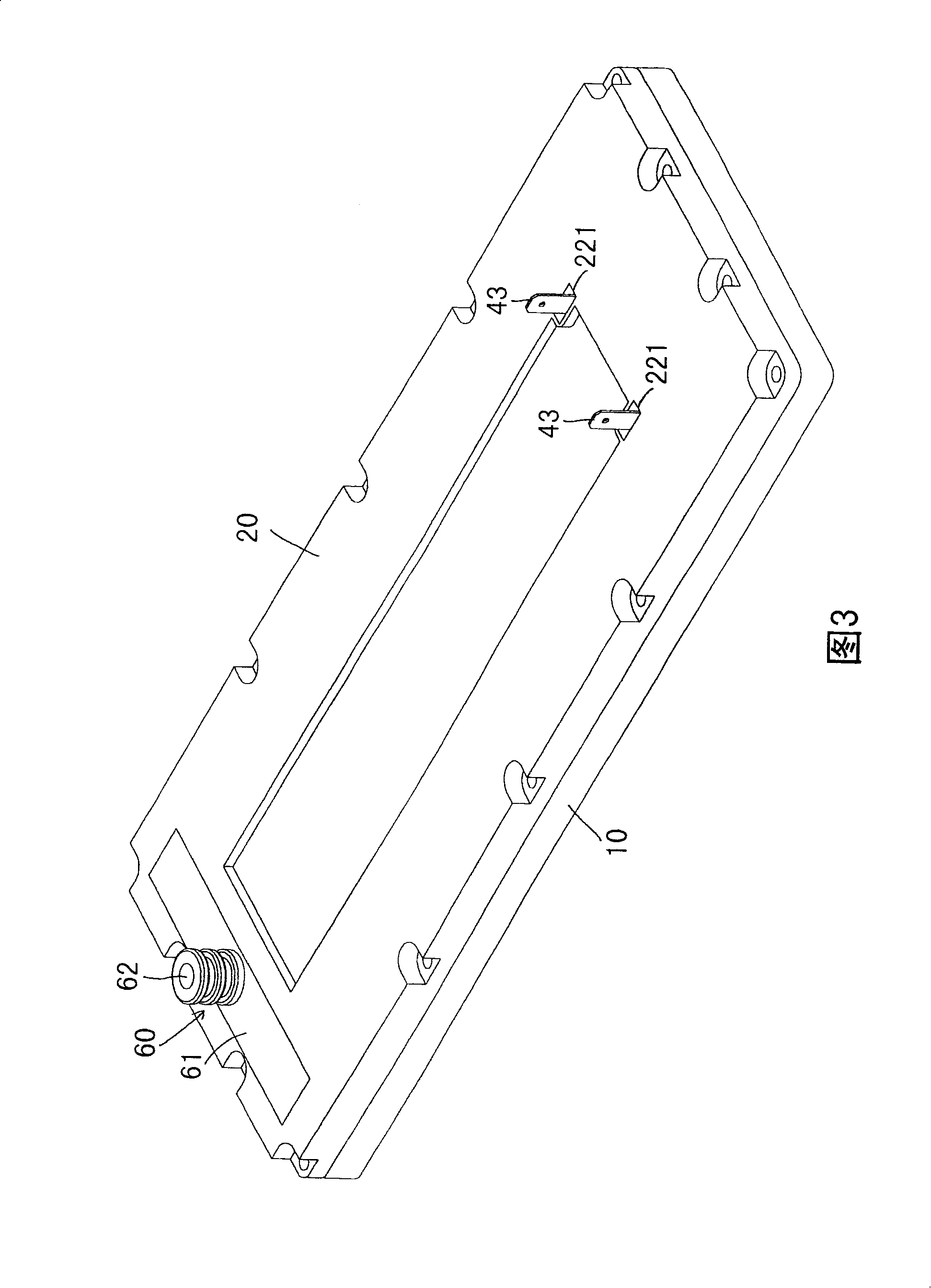

[0149] Embodiment 1, referring to Fig. 3, Fig. 4 shows the three-dimensional combination and the three-dimensional combination sectional view of the first embodiment of the present invention. FIG. 5 is a three-dimensional exploded view of Embodiment 1 of the present invention. And FIG. 6 is a cross-sectional schematic diagram of Embodiment 1 of the present invention. The electrolytic cell is mainly composed of a first housing 10, a second housing 20, two anode electrode plates 30, two cathode electrode plates 40, an acidic water outlet 50, and an alkaline water outlet 60; wherein:

[0150] The inner surface of the first housing 10 is provided with a frame-shaped groove 11, which can be used for setting the water-stop bead Q, and at the same time, it is used for positioning when combined with the second housing 20, and the surrounding can be tightly combined with the second housing 20 by locking components In one piece, a raw water inlet 12 is provided in the middle of the out...

Embodiment 2

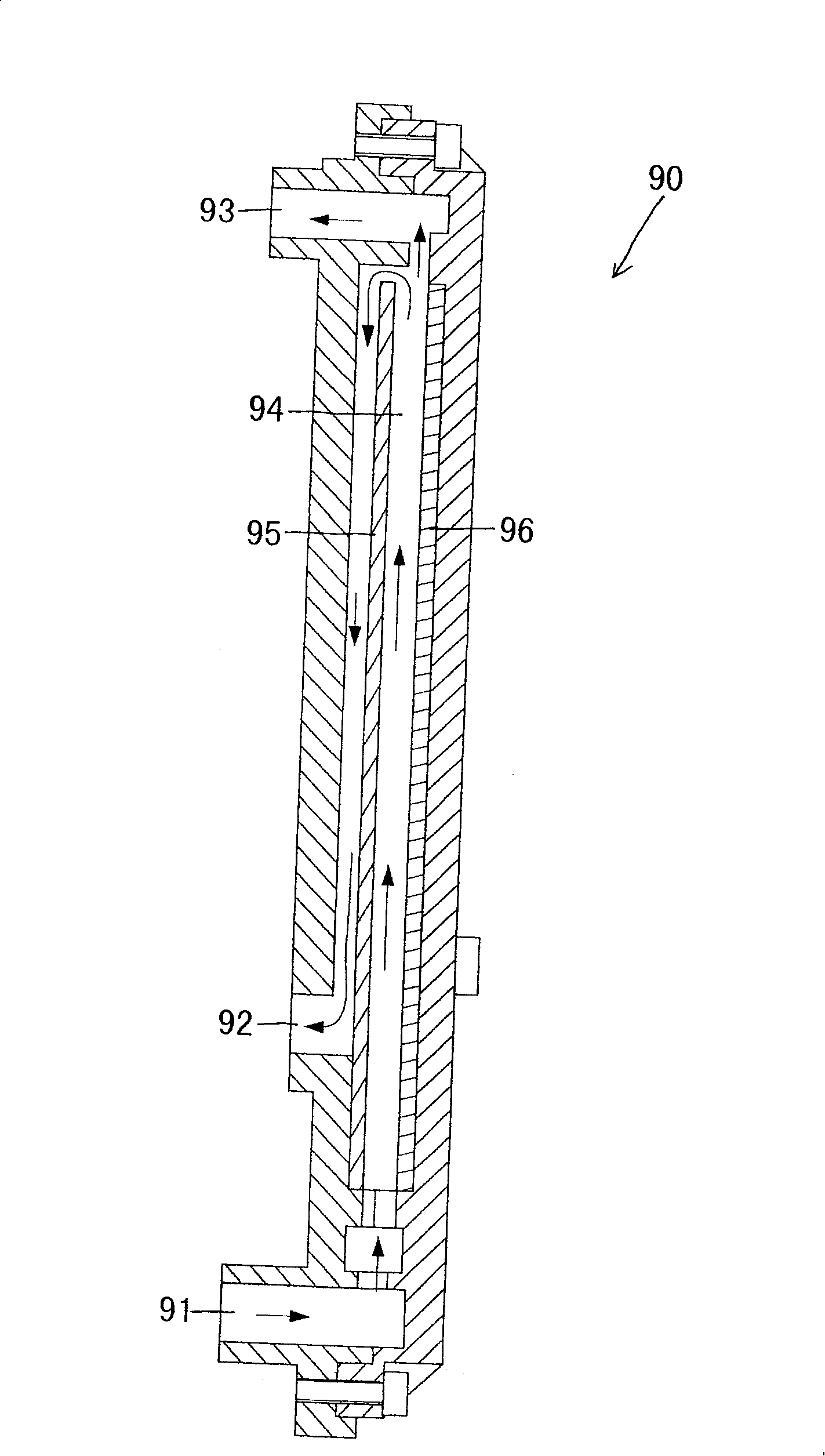

[0159] Embodiment 2, please refer to FIG. 10, which shows the three-dimensional combination and the three-dimensional combination cross-sectional view of the second embodiment of the present invention. As shown in FIG. 12 , it is a three-dimensional exploded schematic view of Embodiment 2 of the present invention. And FIG. 13 is a cross-sectional schematic diagram of Embodiment 2 of the present invention. The electrolytic cell is mainly composed of a first shell 10', a second shell 20', an anode electrode plate 30', a cathode electrode plate 40', an acidic water outlet 50', an alkaline water outlet 60', an electrolytic water machine 70' consisting of:

[0160] The inner surface of the first housing 10' is provided with a frame-shaped groove 11', which can be used to set the water-stop bead Q', and at the same time, it is used for positioning when combined with the second housing 20', and the locking components and the second housing can be used around it. The body 20' is clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com