Electrolytic-biological anaerobic reactor and technique thereof

An anaerobic reactor and reactor technology, which are applied in the fields of anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of difficult operation and management of processes and difficult control of biological processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

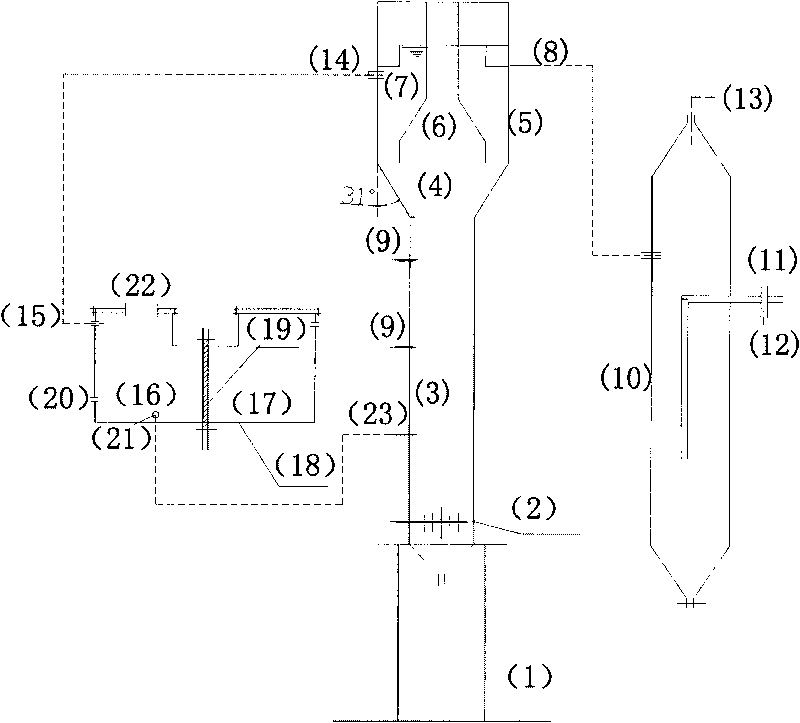

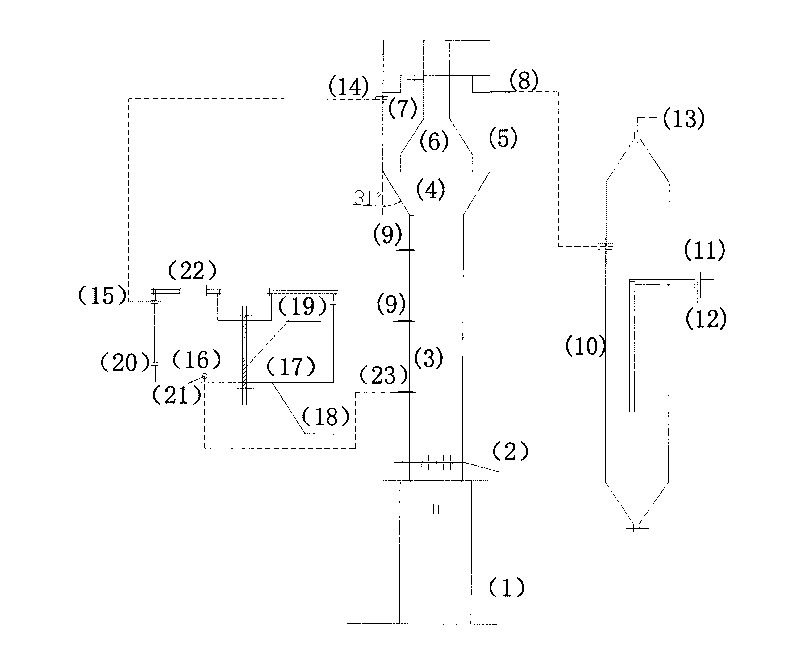

[0024] As shown in the drawings, the electrolysis-biological anaerobic reactor is equipped with a reactor body on the reactor bracket 1, and the reactor body is sequentially provided with a reactor water inlet 2, an upflow reaction chamber 3, a gradual Expansion chamber 4, sludge settling chamber 5, a three-phase separator 6 is arranged in the middle of the sludge settling chamber 5, an overflow weir 7 and a reactor return outlet 14 are arranged on the upper part of the sludge settling chamber 5, and the overflow weir 7 is provided with The overflow weir outlet 8 is provided with a sampling port 9 in the upflow reaction chamber 3, and the electrolyzer 18 is divided into an anode tank 16 and a cathode tank 17 by a cation exchange membrane 19, and the anode tank 16 is provided with an electrolyzer water inlet 15, sampling Port 20, electrolyzer water outlet 21, wire inlet 22, reactor backflow outlet 14 is connected with electrolyzer water inlet 15, electrolyzer water outlet 21 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com