Surface grinding and electrolytic composite processing device, system and method

A composite machining and surface grinding technology, applied in the field of grinding and electrolytic composite machining, can solve the problems of hindering electrochemical reaction, the processing method can not meet the needs of actual engineering, and the machining accuracy is difficult to guarantee, so as to reduce the surface roughness of the workpiece. , low-cost processing, the effect of improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

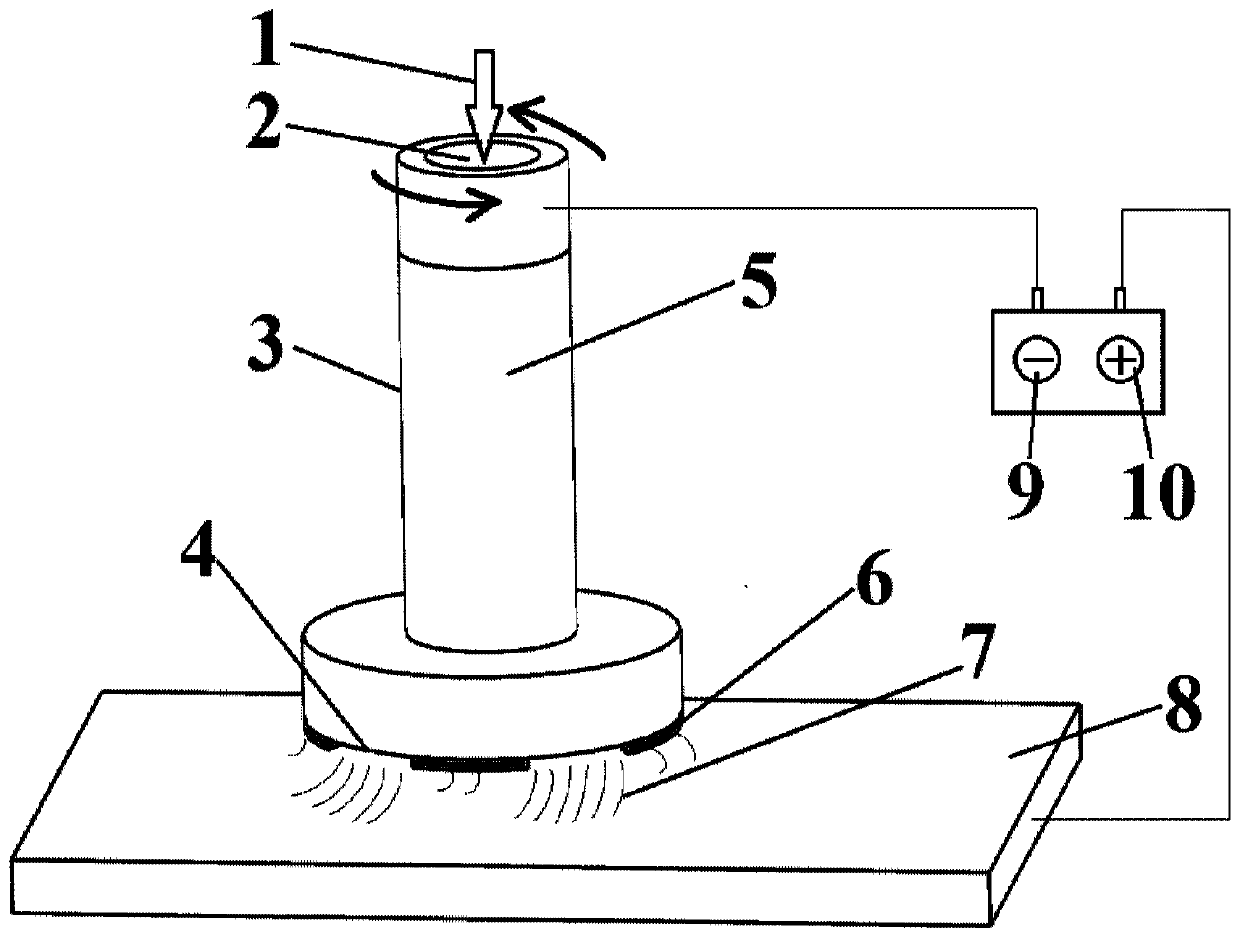

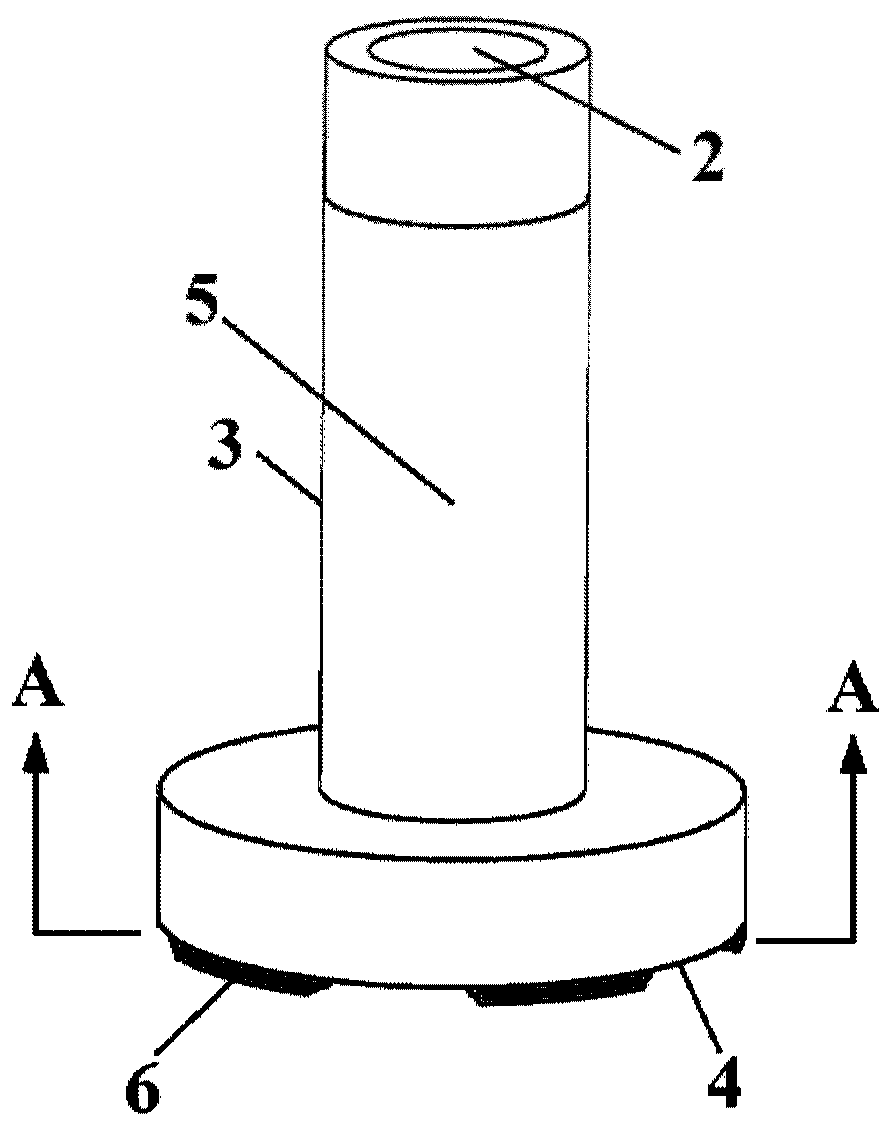

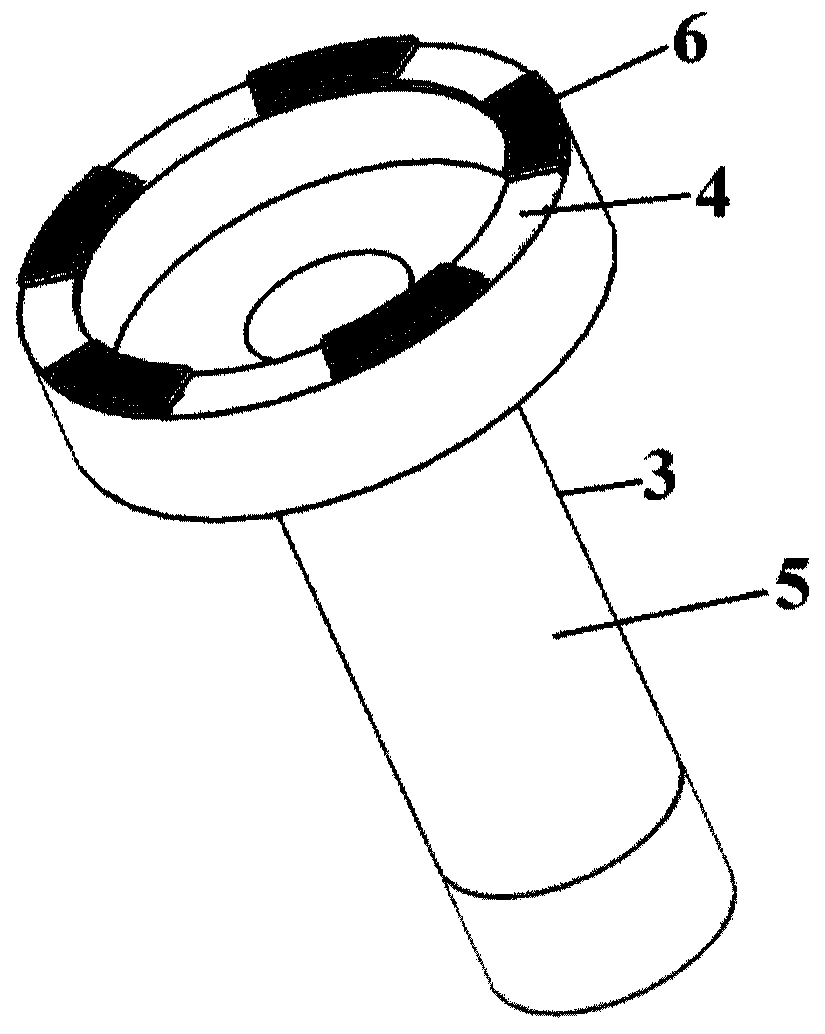

[0052] Such as figure 1 Shown is a schematic diagram of the surface grinding and electrolytic composite processing system, the cup-shaped grinding wheel 5 (ie, the grinding body) is connected to the negative electrode 9 of the power supply as the electrolytic machining cathode, and the workpiece 8 to be processed (ie, the workpiece) is connected to the positive electrode of the power supply 10 as the electrolytic machining anode; The bottom of the cup-shaped grinding wheel 5 is inlaid with a diamond grinding wheel block 6 (ie, a grinding block), which can carry out plane grinding.

[0053]The cup-shaped grinding wheel 5 and the workpiece 8 to be processed form a cavity, but because the grinding wheel block 6 embedded in the bottom of the cup-shaped grinding wheel 5 is higher than the electrolysis area 4, a gap is formed in the lower part of the electrolysis area 4, and most of the electrolyte can flow from the Flow out from this gap, pass through the electrolytic machining are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com