Method for machining optical lens with three radii

A technology of optical lenses and processing methods, which is applied in optical surface grinders, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to realize batch processing of multiple radius parts, inability to realize processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

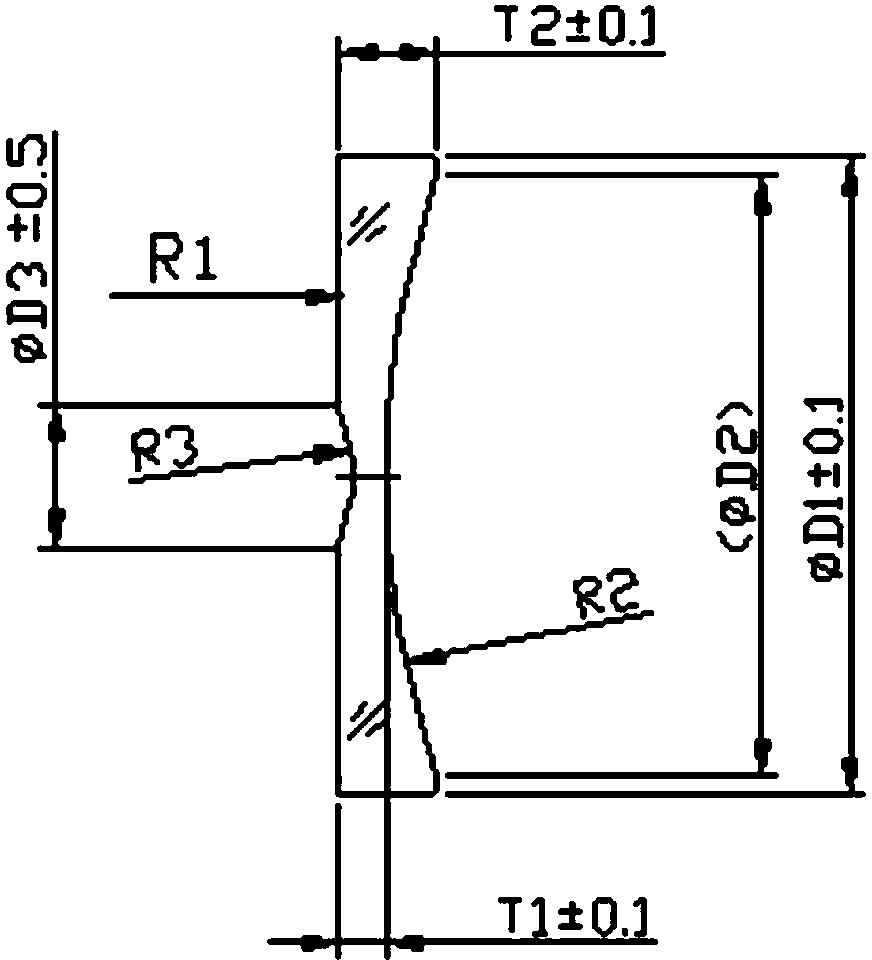

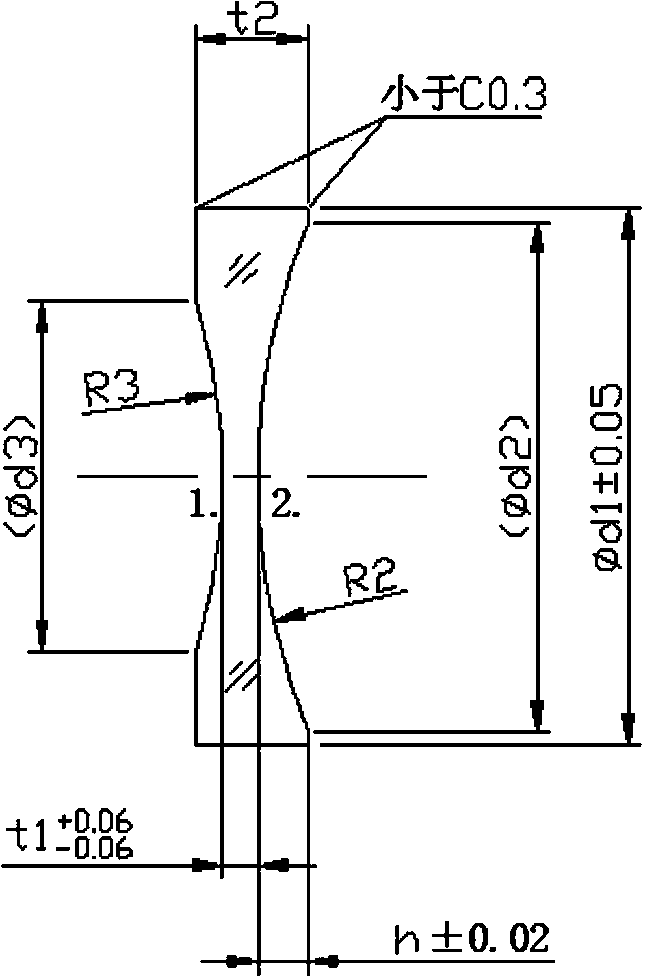

[0014] Such as figure 1 , 2 The finished drawing of optical lens products with 3 radii shown, and its specific processing flow:

[0015] Milling - fine grinding - edging - polishing - milling - fine grinding - polishing - coating; the 3 radius optical lens products are processed twice according to the above processing technology,

[0016] Among them, the first processing: realize the grinding processing of R2 and R3 surfaces, and at the same time, the center thickness and arc height meet the control requirements. Due to the very small diameter of the R3 surface (see figure 1 , 2 ), in order to realize the processing of this radius, the thickness of the blank should be increased by more than 0.7mm, and the diameter can reach a relatively large value during milling and grinding, generally 22~28mm, which can not only process this diameter, but also ensure the milling of the R1 surface during the secondary process Grinding, fine grinding allowance.

[0017] The secondary proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com