Polishing paste used for sapphire round-rod bakelite wheel and preparation method thereof

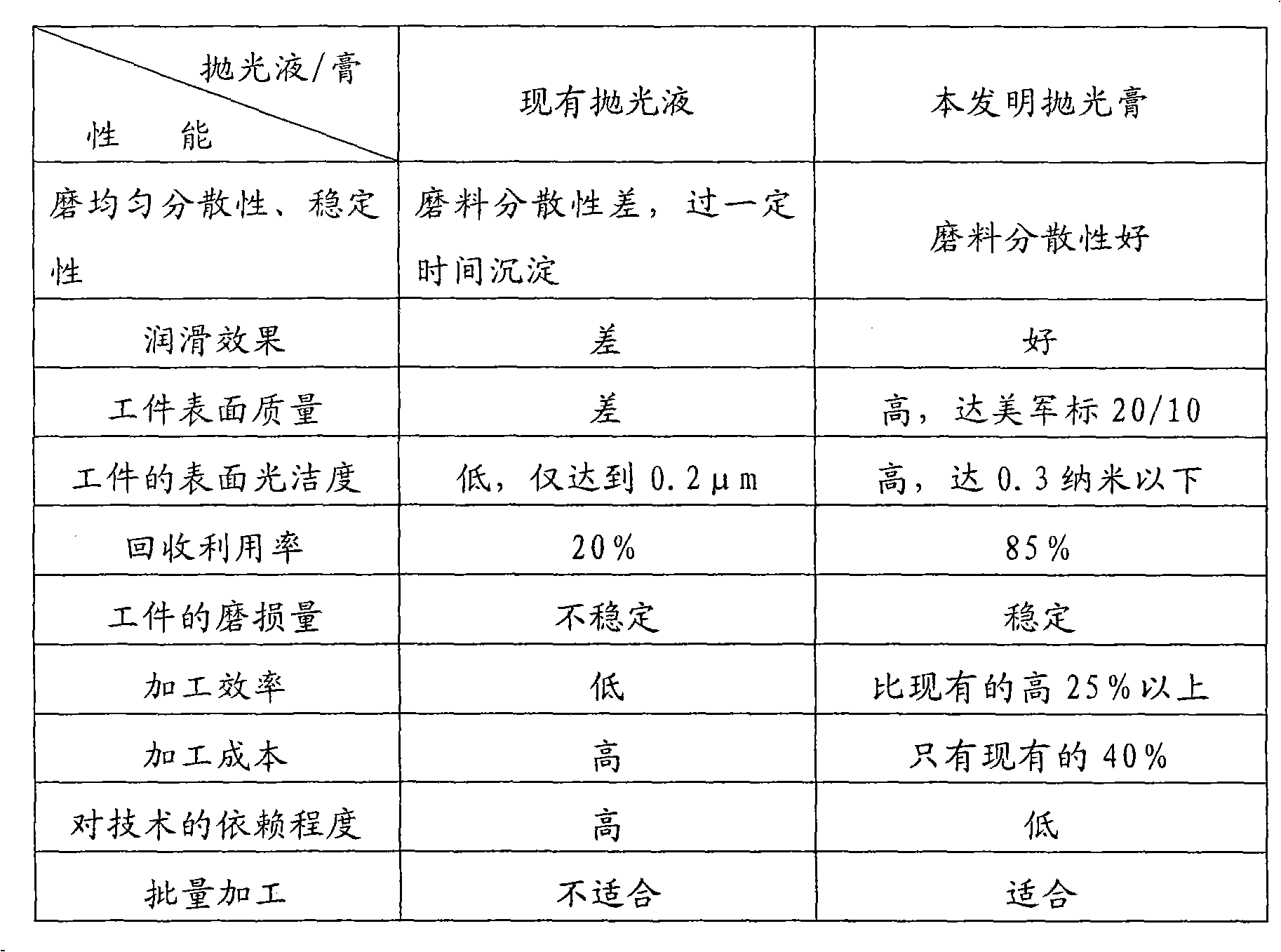

A polishing paste and sapphire technology, applied in the field of polishing paste, can solve the problems of high experience and technical requirements of production workers, uneven abrasive concentration, high processing cost, and achieve high quality and surface finish, low experience and technical level, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The required components of the polishing paste are configured according to Table 2, wherein the vegetable oil of this embodiment is salad oil.

[0028] Table 2

[0029] serial number

Vaseline (g)

vegetable oil (g)

1

3

180

135

2

4

240

180

3

5

300

200

4

6

360

270

[0030] Preparation method of polishing paste:

[0031] (1) Weighing: Put a layer of clean white paper on the electronic balance, take the nano-diamond powder with a medicine spoon and place it on the white paper, and accurately weigh the nano-diamond powder as described in Table 2.

[0032] (2) Baking: Put the white paper containing the nano-diamond powder together on a heating platform, bake at a temperature of 100° C. for 120 minutes, and then take it out and cool it in the air for 30 minutes.

[0033] (3) Grinding: grind in a medium-sized agate mortar, grind and di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com