Synthesis method of polycarboxylic efficient concrete water reducer for high-performance prefabricated parts

A high-efficiency water-reducing agent and polycarboxylic acid-based technology, which is applied in the field of high-molecular polycarboxylic acid addition-copolymerization type high-efficiency water-reducing agent and its synthesis, can solve the problems of inability to meet high-performance prefabricated components, and achieve significant economic benefits and social benefits, good apparent quality and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

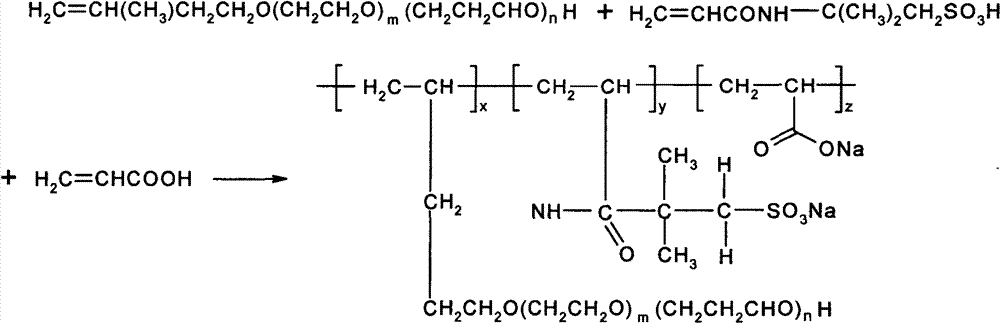

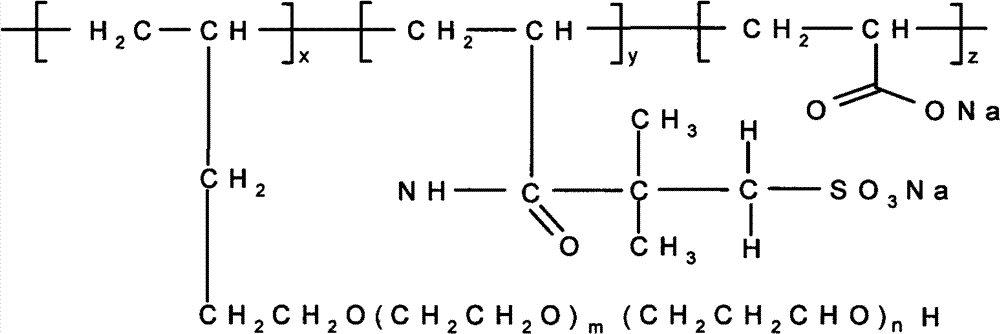

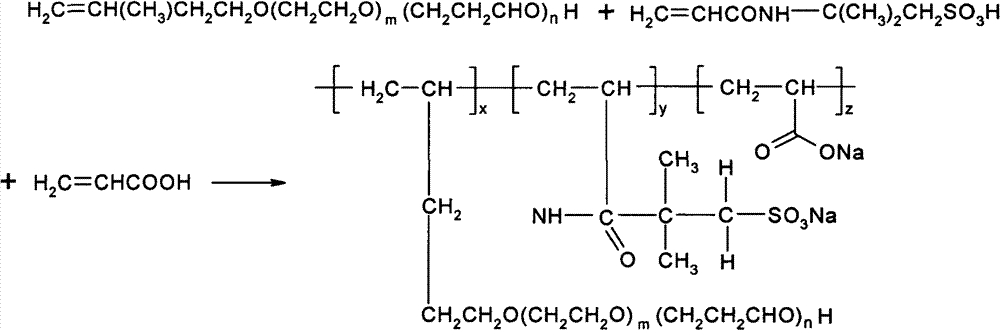

Method used

Image

Examples

Embodiment 1

[0021] In a 1000ml flask equipped with a thermometer and a stirrer, first add 200g of pure water, when the temperature rises to 50-60°C, add 375g of methyl alkenyl polyoxyethylene ether polyoxypropylene ether and 3g of hydrogen peroxide, heat up and stir to 60-60°C At 65°C, add solution A (0.5g ascorbic acid + 1g thioglycolic acid + 100-150g water) and solution B (30g acrylic acid + 5g 2-acrylamide-2 methylpropanesulfonic acid + 10- 20g); the time for adding liquid A is 4-4.5 hours, and the time for adding liquid B is 3.5-4 hours. After the dropwise addition, keep warm for 1-3 hours to make the reaction complete. After cooling, neutralize with sodium hydroxide to pH=5.5±0.5, add water to adjust to the specified concentration, and obtain a colorless transparent viscous liquid with a solid content of about 40%. , to adjust the air content.

[0022] It is measured that when the dosage is 0.5% of the cement mass, the fluidity of the slurry is more than 200mm, and the concrete wat...

Embodiment 2

[0024] In a 1000ml flask equipped with a thermometer and agitator, first add 200g of pure water, when the temperature rises to 50-60°C, add 375g of methyl alkenyl polyoxyethylene ether polypropylene ether and 3g of hydrogen peroxide, heat up and stir to 60-65°C At ℃, use a constant pressure dropping funnel to add solution A (1g ascorbic acid + 1.5g thioglycolic acid + 100-150g water) and solution B (30g acrylic acid + 5g 2-acrylamide-2 methylpropanesulfonic acid + 10-20g water) ); the time for adding liquid A is 4-4.5 hours, and the time for adding liquid B is 3.5-4 hours for 2-acrylamido-2 methylpropanesulfonic acid. After the dropwise addition, keep warm for 1-3 hours to make the reaction complete. After cooling, neutralize with sodium hydroxide to pH=5.5±0.5, add water to adjust to the specified concentration, and obtain a colorless transparent viscous liquid with a solid content of about 40%. , to adjust the air content.

[0025] When the measured mixing amount is 0.5% of...

Embodiment 3

[0027] In a 1000ml flask equipped with a thermometer and agitator, first add 200g of pure water, when the temperature rises to 50-60°C, add 375g of methyl alkenyl polyoxyethylene ether polypropylene ether and 3g of hydrogen peroxide, heat up and stir to 60-65°C At ℃, use a constant pressure dropping funnel to add solution A (1g ascorbic acid + 2g thioglycolic acid + 100-150g water) and solution B (30g acrylic acid + 5g 2-acrylamide-2 methylpropanesulfonic acid + 10-20g water) ; Control the time of adding liquid A to be 4-4.5 hours, and the time of adding liquid B to be 3.5-4 hours. After the dropwise addition, keep warm for 1-3 hours to make the reaction complete. After cooling, neutralize with sodium hydroxide to pH=5.5±0.5, add water to adjust to the specified concentration, and obtain a colorless transparent viscous liquid with a solid content of about 40%. , to adjust the air content.

[0028] When the measured mixing amount is 0.5% of the cement mass, the fluidity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com