Dedicated digit controlled machine tool for processing roll surface pattern and its operation method

A CNC machine tool and pattern technology, applied in metal processing machinery parts, digital control, metal processing equipment, etc., can solve the problems of uneven pattern of anti-skid walking platform steel plate, difficult to meet demand, poor processing accuracy, etc., to achieve apparent quality Good, high production efficiency, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

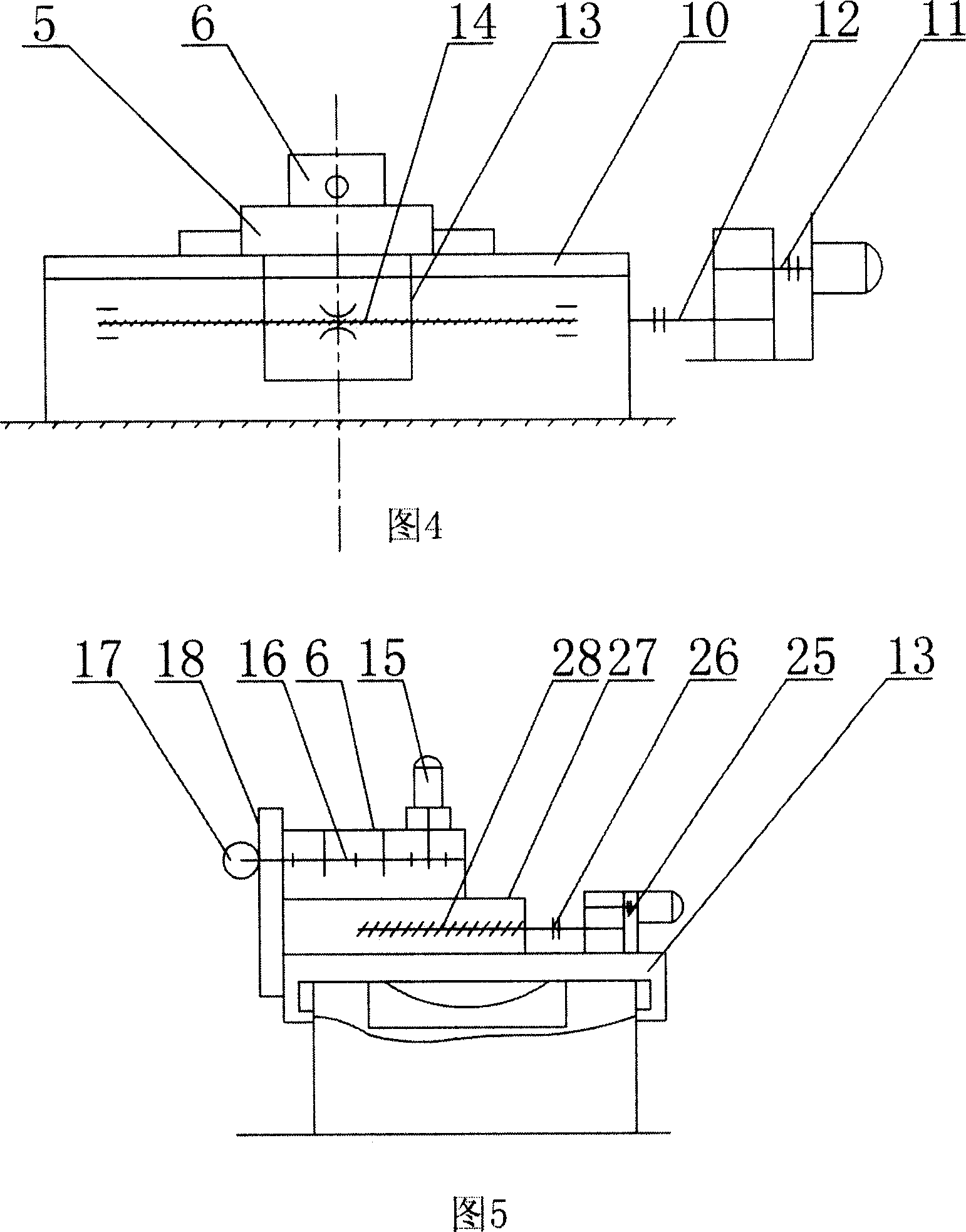

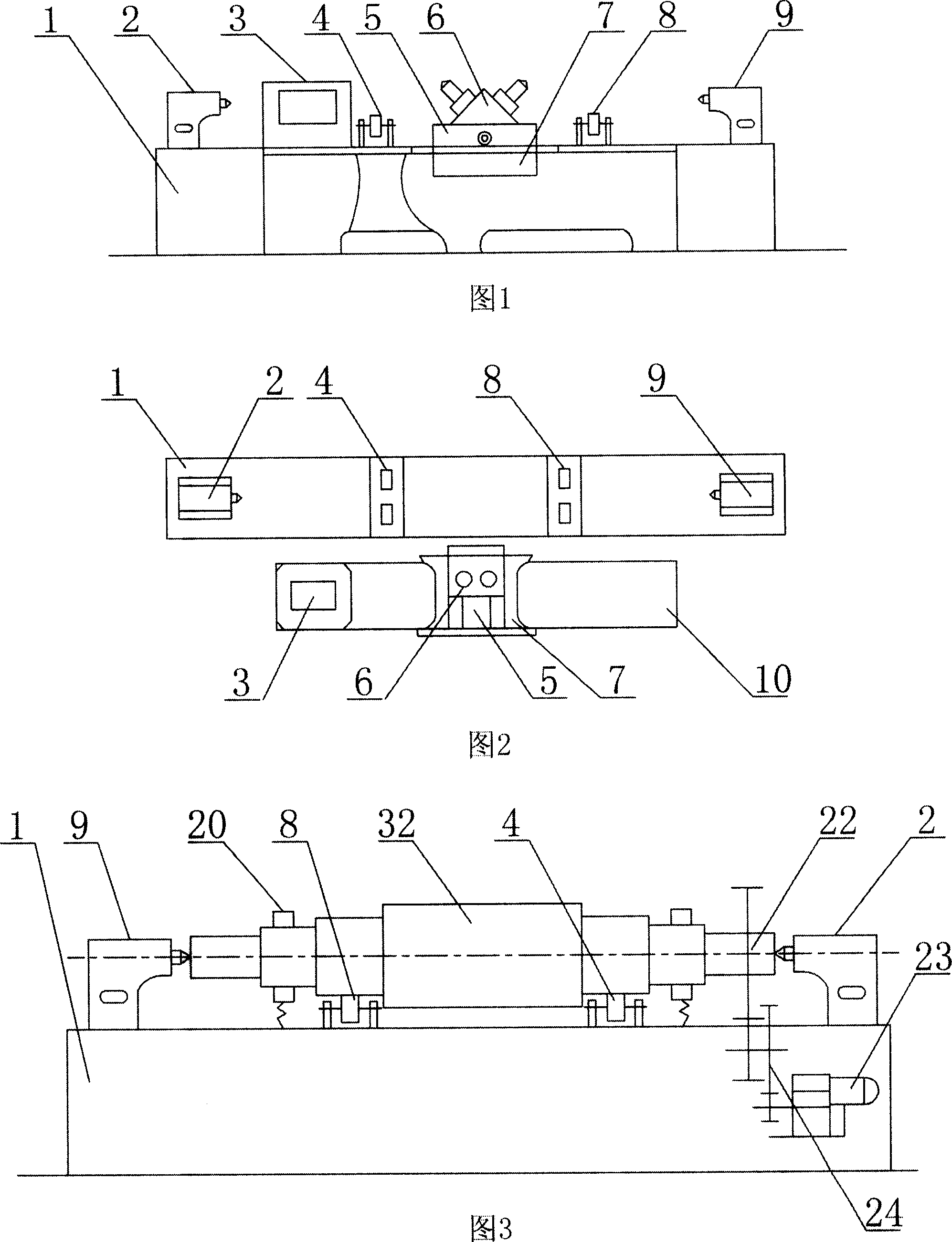

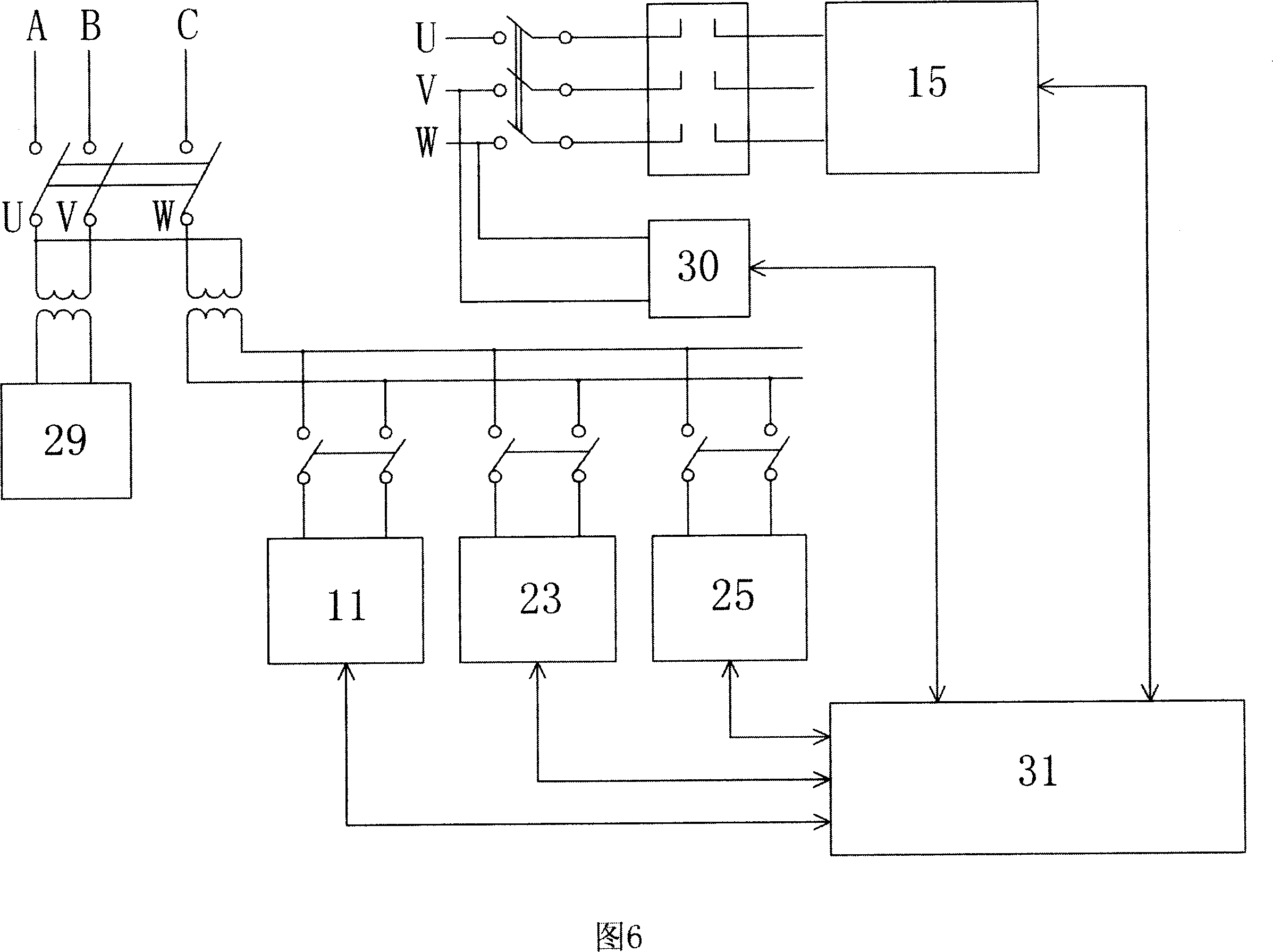

[0033] As shown in Fig. 1, Fig. 2, Fig. 3, according to a kind of special-purpose numerical control machine tool that is used for processing roll surface pattern of the present invention, comprise numerical control device 3, machine tool power system, it is characterized in that by the machine tool table 1 that is arranged side by side And machine tool guide rail 10, be installed on the circular milling cutter driving mechanism on this machine tool guide rail 10, be located at the left and right roller support 4,8 on the machine tool workbench 1, be located at the left and right roller support 4 on the machine tool workbench 1 , Electromagnetic locking device 19,20 of 8 both sides, is located at the indexing mechanism in the machine tool workbench 1, is located at the left machine tool tailstock 2 on the left side of the left roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com