Conductive silicone rubber with electromagnetic shielding performance and manufacturing method

An electromagnetic shielding, conductive silicon technology, applied in the field of conductive silicone rubber and its preparation, to achieve the effects of reducing material consumption, excellent electromagnetic shielding performance, high electrical conductivity and magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

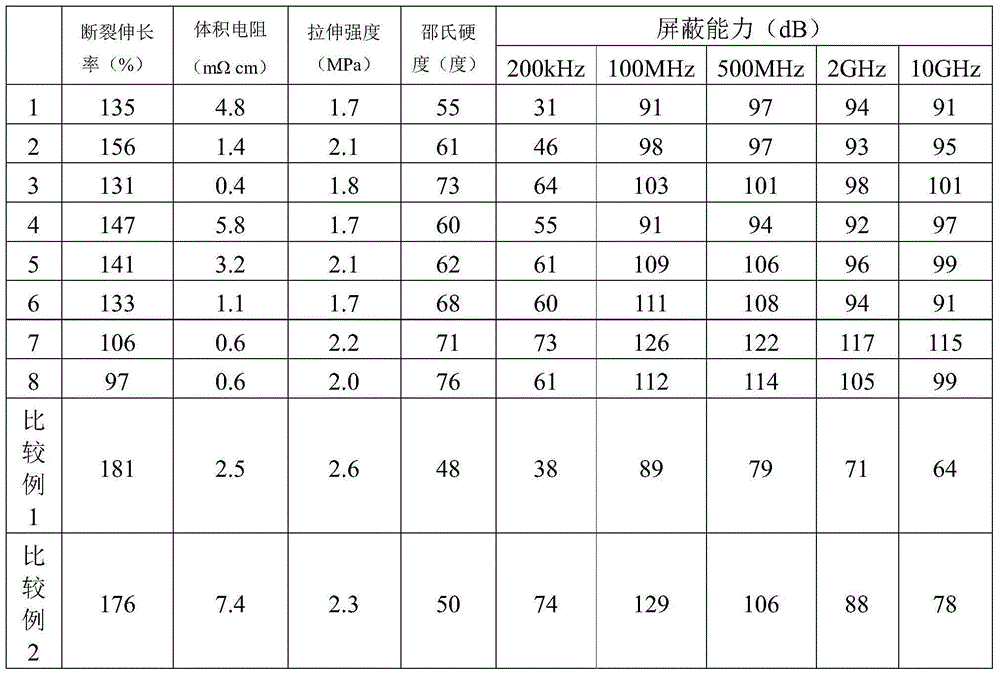

Examples

Embodiment 1

[0034] 1) Mix hydroxyl silicone rubber, isocyanate, silver-plated nickel powder and silver-plated copper powder in a ratio of 100:1:300:300 on a double-roller mill for 1 hour at a temperature of 80°C;

[0035] 2) Put the composite material kneaded in step 1 into a flat vulcanizer at 100° C. and 8 MPa for compression molding.

Embodiment 2

[0037] 1) Mix hydroxyl silicone rubber, isocyanate, silver-plated nickel powder and silver-plated copper powder in a ratio of 100:4:300:450 on a double-roll mill for 1 hour at a temperature of 100°C;

[0038] 2) Put the composite material kneaded in step 1 into a flat vulcanizing machine at 120° C. and 5 MPa for compression molding.

Embodiment 3

[0040] 1) Mix hydroxyl silicone rubber, isocyanate, silver-plated nickel powder and silver-plated copper powder in a ratio of 100:8:300:600 on a double-roller mill for 0.5h at a temperature of 120°C;

[0041] 2) Put the composite material kneaded in step 1 into a flat vulcanizer at 180° C. and 5 MPa for compression molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com