Layered electromagnetic shielding packaging structure and packaging structure manufacturing method

A packaging structure and electromagnetic shielding technology, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as difficulty in meeting the individual shielding requirements of electronic products and cumbersome packaging processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

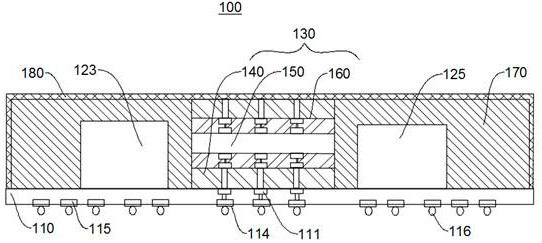

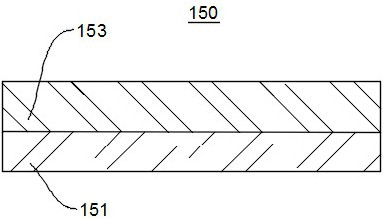

[0051] Please refer to figure 1 , the present embodiment provides a layered electromagnetic shielding packaging structure 100, including a module substrate 110, a shielding device 130 and a plurality of chips, the plurality of chips are arranged on the module substrate 110 at intervals, and at least two adjacent chips A shielding device 130 is provided between them. In this embodiment, the multiple chips include a second chip 123 and a third chip 125, the shielding device 130 includes a bottom shielding layer 140, an intermediate layer 150, and a top shielding layer 160 stacked, and the module substrate 110 is provided with a first contact. The point 111 is connected to a second ground point (not shown in the figure), the bottom shielding layer 140 is electrically connected to the first ground point 111 , and the top shielding layer 160 is electrically connected to the second ground point. The module substrate 110 is provided with a first package body 170 for plastic sealing ...

no. 2 example

[0063] An embodiment of the present invention provides a method for manufacturing a packaging structure, which mainly includes the following steps:

[0064] S100: Fabricate the shielding device 130. Wherein, the shielding device 130 includes a bottom shielding layer 140 , a middle layer 150 and a top shielding layer 160 .

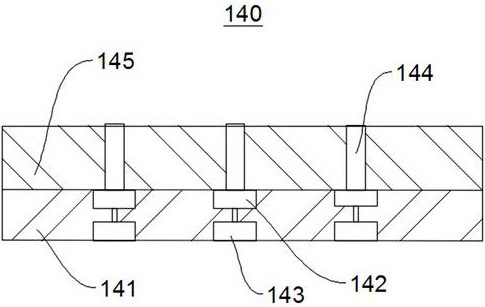

[0065] Please refer to Figure 5 , combined with figure 1 , S110: the steps of making the bottom shielding layer 140 and the top shielding layer 160 respectively include:

[0066] A first substrate 141 is provided, a first pad 142 is provided on the front side of the first substrate 141, a second pad 143 is provided on the reverse side of the first substrate 141, and the first pad 142 and the second pad 143 pass through the first substrate 141 The internal circuit is electrically connected. A metal post 144 is disposed on the first pad 142 , and the metal post 144 is used to electrically connect with the first ground point 111 or the second ground point. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com