Protection method of high-corrosion-resistance airborne aluminum-based LRM module

A high-corrosion-resistant, aluminum-based technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of poor corrosion resistance of the natural conductive oxide film layer, achieve good manufacturability, improve electromagnetic shielding performance Corrosion resistance, the effect of simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

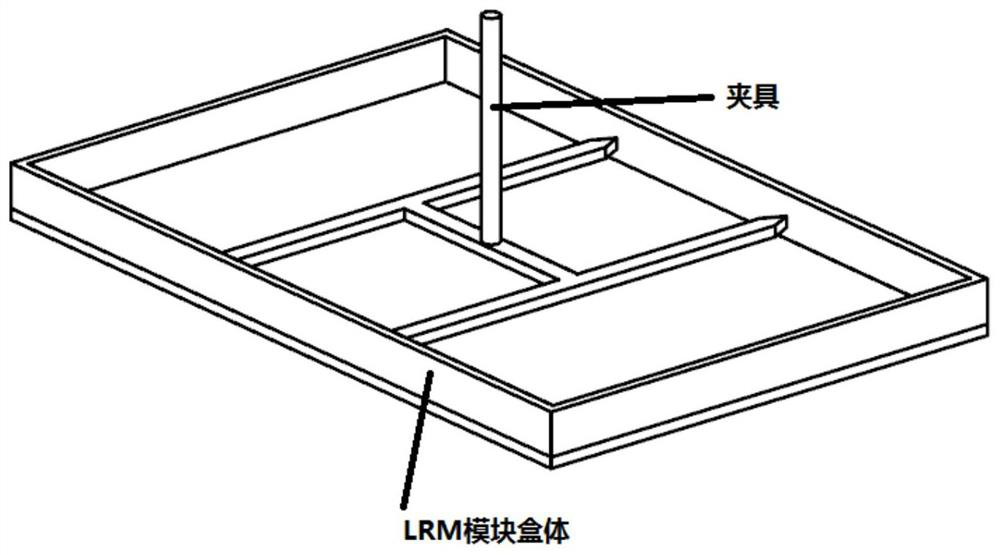

[0014] refer to figure 1 .According to the present invention, in combination with the structural form of the LRM module parts, select a suitable mounting method and hanger, install the LRM module parts on the hanger during the oxidation process, and fix the LRM module parts; put the mounted LRM module parts into Pre-treatment in the degreasing-alkaline etching solution to remove oil and scale on the surface of the product, and then pickling solution is selected according to the material of the LRM module parts for pickling, sulfuric acid is used for anti-rust aluminum, and hydrofluoric acid is used for silicon-containing materials to remove Floating ash, loose substances and impurities on the surface of the product, and use three-stage flowing water to clean the LRM module parts, and put the cleaned product into a plastic tank, PP / PVC tank or 304 stainless steel tank. Oxidation treatment, the oxidation time is within 4 to 6 minutes. The oxidized LRM module parts are washed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com