A kind of dual functional layer polymer composite material and preparation method thereof

A dual-function, composite material technology, applied in the field of polymer composite materials, can solve the problems of inability to protect the wiring harness system, lack of electromagnetic wave shielding, and limit the application of polymer shape memory materials, so as to improve the shielding effect and meet the electromagnetic shielding requirements. The effect of excellent heat and humidity resistance and salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

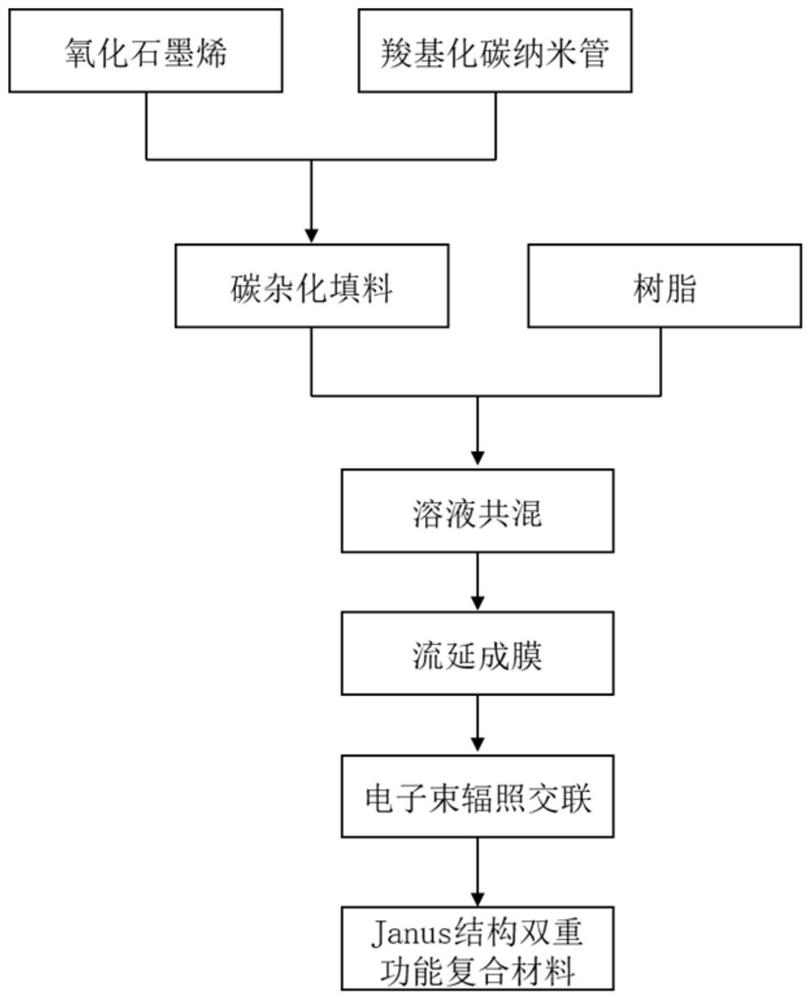

Method used

Image

Examples

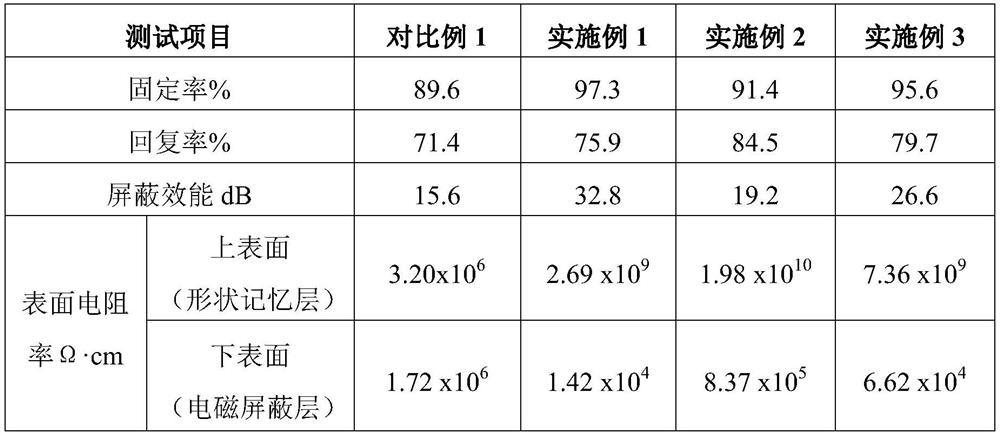

Embodiment 1

[0027] First, 0.5 g of graphene oxide (Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, brand: TNGO-10) was dispersed in 50 g of deionized water, ultrasonicated for 2 h to form a uniform dispersion, and the pH was adjusted to 5 with hydrochloric acid, and then Add 0.05g of γ-aminopropyltriethoxysilane into 0.25g of ethanol to make it dissolve with stirring, add it to the above dispersion liquid, and react at 70°C for 6h. Cool to room temperature, centrifuge and wash 5 times with deionized water to remove unreacted coupling agent. The chemically modified graphene oxide was obtained by freeze-drying at a pressure of 10 Pa and a temperature of -55° C. for 48 hours.

[0028] Add 0.5 g of carboxylated single-walled carbon nanotubes (Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, brand: TNSSC) and 50 g of thionyl chloride solvent into the reaction kettle, ultrasonicate at room temperature for 3 h, and then react at 90 ° C for 24 h. After room tem...

Embodiment 2

[0032] First, disperse 0.5g of graphene oxide (Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, brand: TNGO-10) in 250g deionized water, ultrasonic 0.5h to form a uniform dispersion, adjust the pH to 4 with hydrochloric acid, and then Add 0.025g of γ-aminopropyltriethoxysilane into 0.25g of ethanol to stir and dissolve it, add it to the above dispersion liquid, and react at 25°C for 24h. Cool to room temperature, centrifuge and wash 3 times with deionized water to remove unreacted coupling agent. The chemically modified graphene oxide was obtained by freeze-drying at a pressure of 10 Pa and a temperature of -55° C. for 24 hours.

[0033] Add 0.5 g of carboxylated double-walled carbon nanotubes (Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, brand: TNDC) and 100 g of thionyl chloride solvent into the reaction kettle, ultrasonicate at room temperature for 1 h, then react at 60 ° C for 12 h, and drop to After room temperature, filter, wash wit...

Embodiment 3

[0037] First, 0.5 g of graphene oxide (Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, brand: TNGO-10) was dispersed in 50 g of deionized water, ultrasonicated for 2 h to form a uniform dispersion, and the pH was adjusted to 5 with hydrochloric acid, and then Add 0.05g of γ-aminopropyltriethoxysilane into 0.25g of ethanol to make it dissolve with stirring, add it to the above dispersion liquid, and react at 70°C for 6h. Cool to room temperature, centrifuge and wash 5 times with deionized water to remove unreacted coupling agent. The chemically modified graphene oxide was obtained by freeze-drying at a pressure of 10 Pa and a temperature of -55° C. for 48 hours.

[0038] Add 0.5 g of carboxylated multi-walled carbon nanotubes (Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, brand: TNSMC1) and 50 g of thionyl chloride solvent into the reaction kettle, ultrasonicate at room temperature for 3 h, then react at 90 ° C for 24 h, down to After room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com