Graphene silver nanowire composite slurry and preparation method thereof

A technology of silver nanowires and composite slurry, which is applied in fireproof coatings, conductive coatings, antifouling/underwater coatings, etc., can solve the problems of non-environmental protection, easy aggregation of silver powder, pollution, etc., and achieve far-infrared heating effect Improved performance, improved electrical conductivity, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

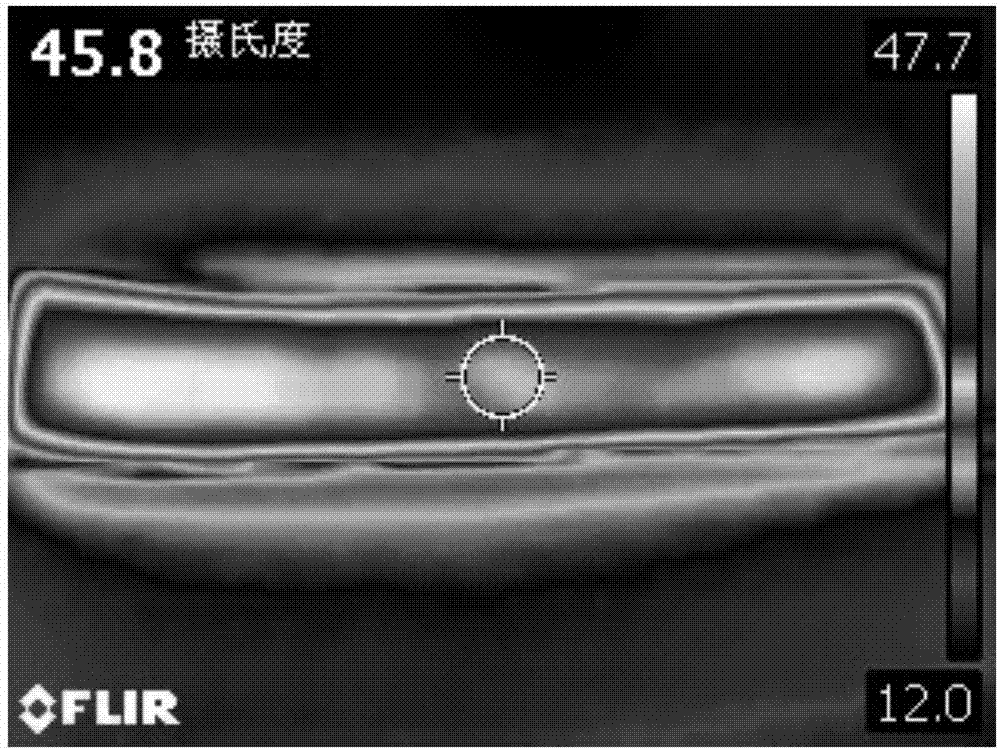

Image

Examples

Embodiment 1

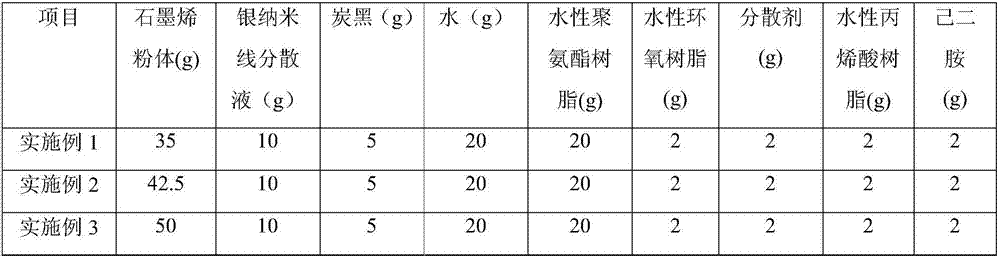

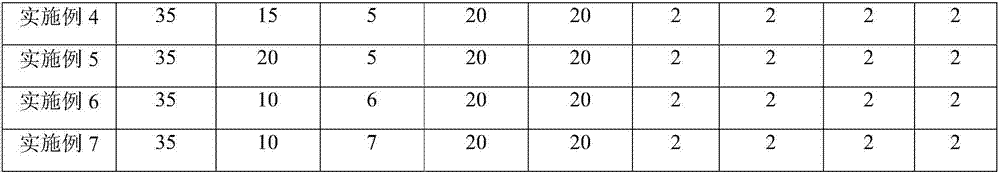

[0036] The present embodiment prepares graphene silver nanowire composite slurry according to the following steps:

[0037] a. According to the ratio, take 35g of graphene powder, 5g of carbon black, 2g of dispersant hydroxypropyl methylcellulose and 30g of water, stir and mix for 0.5h, then ultrasonically disperse for 1h, then add 20g of water-based polyurethane resin, and put it in a ball mill Disperse by high-speed ball milling, and finally filter through a 250-mesh mesh cloth to obtain mixed slurry A;

[0038] b. Add 10g of 10mg / mL silver nanowire dispersion (100nm in diameter, 50-100μm in length), 2g of water-based epoxy resin and 2g of water-based acrylic resin into a vacuum mixer for vacuum defoaming and mixing evenly to obtain a mixed solution B;

[0039] c. Add the mixed slurry A to the vacuum mixer, and under continuous stirring, add a pH buffer to adjust the pH to 8, then add the mixed solution B and 2 g of the curing agent hexamethylenediamine in sequence, and cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com