Graphene oxide-ferroferric oxide magnetic liquid-cement based composite material and preparation method thereof

A composite material and graphene technology, which is applied in the field of graphene oxide-ferric oxide ferrofluid-cement-based composite materials and its preparation, can solve the problems that it is difficult to achieve uniform distribution of graphene and cannot be used to stir evenly. Achieve the effect of compact structure, good electromagnetic shielding performance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

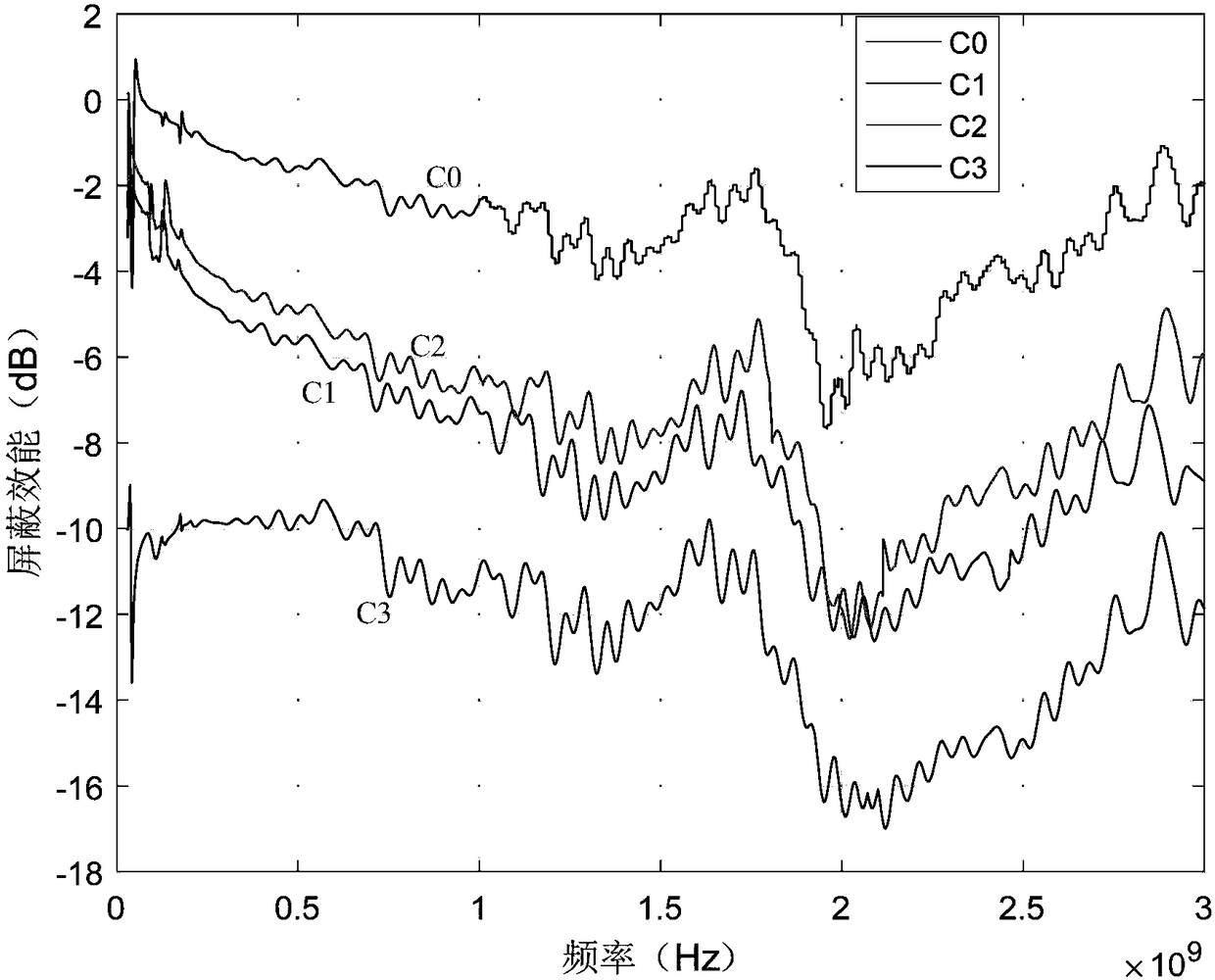

Embodiment 1

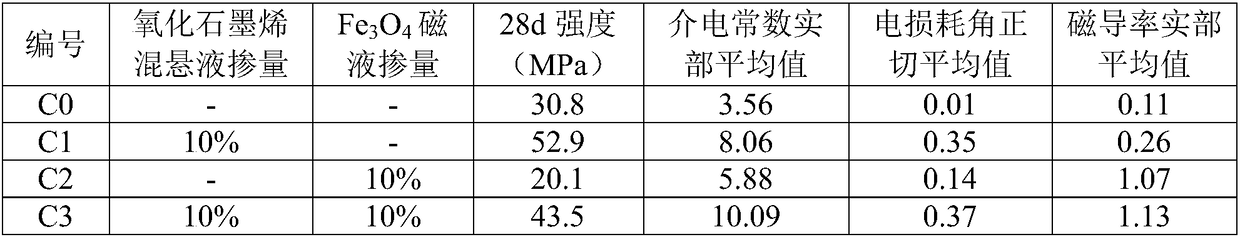

[0035] Step A: Prepare ordinary cement-based composite material, numbered C0. Use ordinary 325 Portland cement with a water-cement ratio of 0.5. Weigh 500g of cement and 250g of water. Pour the cement powder into the slurry mixer. After stirring for 10 seconds, pour in water and continue stirring for 2 minutes. Pour the stirred cement slurry into the mold, smooth the surface, remove the mold after standing for 24 hours, put it in a standard curing box (20°C, 98% humidity) for 28 days, and take it out for use.

[0036]Step B: Prepare graphene oxide-cement based composite material, numbered C1. Ordinary 325 Portland cement is used, the water-cement ratio is 0.4, 500g of cement, 200g of water, and 50g of graphene oxide suspension are weighed. Pour the cement powder into the slurry mixer, and after stirring for 10 seconds, pour in water, continue stirring for 2 minutes, pour in the graphene oxide suspension, and stir for 1 minute. Pour the cement slurry that has been stirred int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com