Modified carbon fiber, and preparation method and application thereof

A technology of modifying carbon and carbon fiber, which is applied in the direction of electrical components, magnetic/electric field shielding, shielding materials, etc., can solve the problems of poor dispersion and easy agglomeration, and achieve the effects of improving electrical conductivity, enhancing roughness, and enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

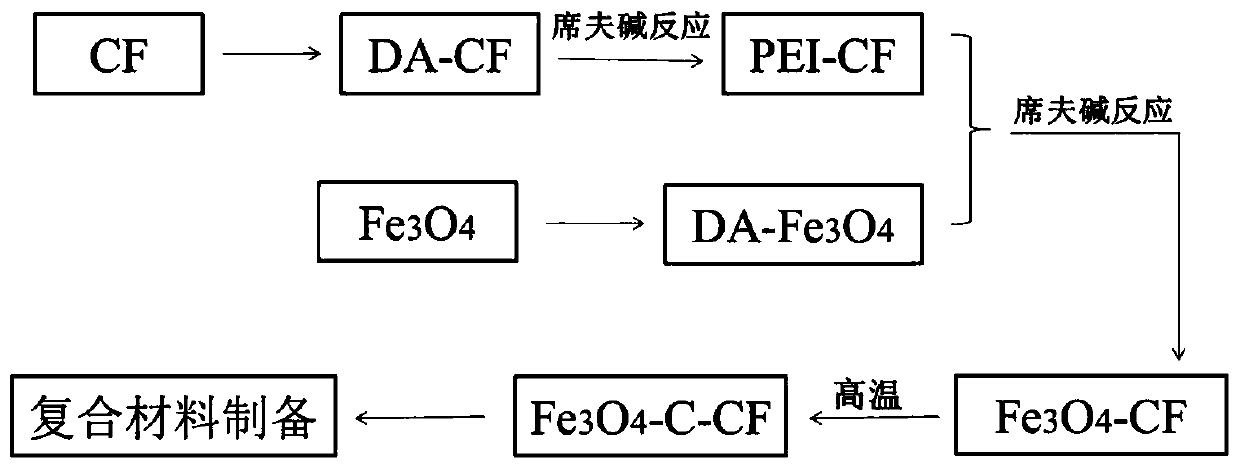

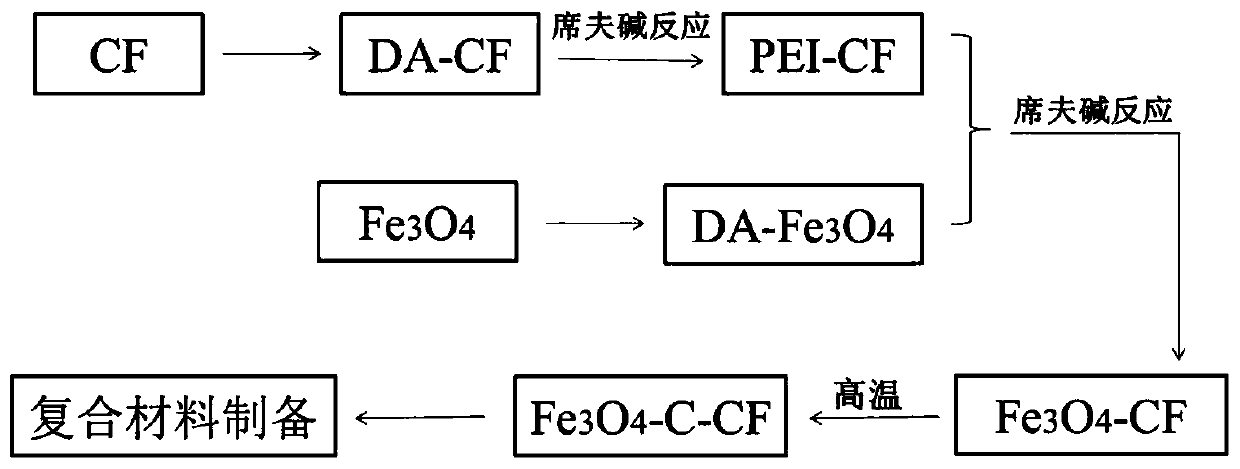

[0056] The present invention also provides a kind of preparation method of modified carbon fiber, comprises the following steps:

[0057] a) Immersing dopamine-modified carbon fibers into a solution containing substance A to obtain substance A-dopamine-modified carbon fibers;

[0058] The substance A is a compound or polymer containing an active amino group;

[0059] b) under alkaline conditions, the substance A-dopamine-modified carbon fiber and dopamine-modified filler are mixed and reacted in the liquid phase to obtain filler-modified carbon fiber;

[0060] The dopamine-modified filler includes dopamine-modified magnetic particles and / or dopamine-modified carbon nanomaterials;

[0061] c) Carrying out carbonization treatment on the filler-modified carbon fibers to obtain modified carbon fibers.

[0062] In the modified carbon fiber preparation method provided by the present invention, firstly provide dopamine modified carbon fiber, the dopamine modified carbon fiber is co...

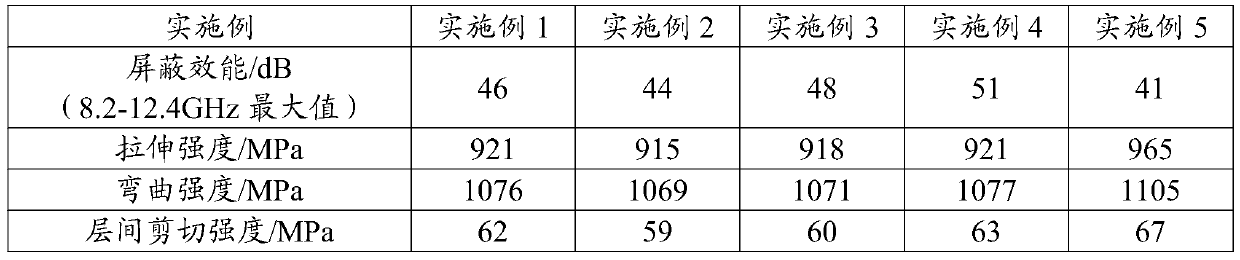

Embodiment 1

[0088] according to figure 1 The process shown in the preparation of composite materials specifically includes the following steps:

[0089] (1) Add dopamine (DA) into the Tris-HCl buffer solution with a pH value of 8.5 to prepare a DA / Tris-HCl buffer solution with a DA concentration of 1 mg / mL and stir evenly; then the desized carbon fiber fabric (CF ) immersed in DA / Tris-HCl buffer solution at room temperature for 12 hours; then washed three times with deionized water and dried at 80-100°C to prepare dopamine-modified carbon fibers (DA-CF).

[0090] (2) Add DA-CF to 1 mg / mL polyethyleneimine solution, and immerse at room temperature for 2 hours to obtain polyethyleneimine-modified carbon fiber (PEI-CF).

[0091] (3) Dopamine (DA) is added to the Tris-HCl buffer solution with a pH value of 8.5 to prepare a DA / Tris-HCl buffer solution with a DA concentration of 1 mg / mL and stir evenly; then ferric iron tetroxide nanoparticles Add to DA / Tris-HCl buffer at room temperature to ...

Embodiment 2

[0096] (1) Add dopamine (DA) into the Tris-HCl buffer solution with a pH value of 8.5 to prepare a DA / Tris-HCl buffer solution with a DA concentration of 2 mg / mL and stir evenly; then the desized carbon fiber fabric (CF ) immersed in DA / Tris-HCl buffer solution at room temperature for 24-36h; then washed three times with deionized water and dried at 80-100°C to prepare dopamine-modified carbon fibers (DA-CF).

[0097] (2) Add DA-CF to 2 mg / mL polyethyleneimine solution, and soak at room temperature for 1-2h to obtain polyethyleneimine-modified carbon fiber (PEI-CF).

[0098] (3) Dopamine (DA) is added to the Tris-HCl buffer solution with a pH value of 8.5 to prepare a DA / Tris-HCl buffer solution with a DA concentration of 2 mg / mL and stir evenly; Add it to DA / Tris-HCl buffer solution to prepare a mixed solution with a Ni concentration of 1 mg / mL, ultrasonicate at 200 W for 60 minutes, then magnetically stir the mixed solution at room temperature for 24 hours; finally wash with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com