Wet smelting method for preparing natural rubber/nanometer silicon dioxide rubber compound

A nano-silica, natural rubber latex technology, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve the problems of low content of natural emulsifier, damage to stability, and high production cost of concentrated natural rubber latex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

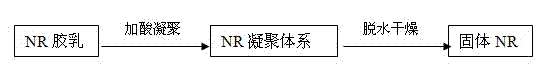

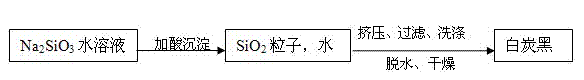

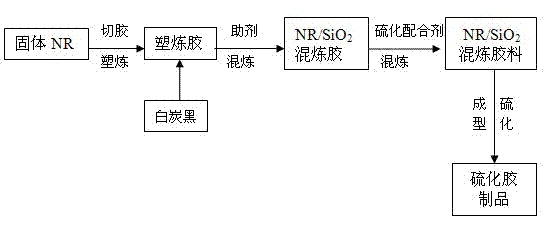

[0039] (1) The basic operation process of preparing natural rubber / nano-silica compound by in-situ generation-wet milling method

[0040] Determination of mass percent concentration of fresh natural rubber latex and SiO of silica sol 2 content. Add fresh natural rubber latex containing 100g of NR dry solids into a stainless steel beaker with a volume of 2 liters equipped with a stirrer and a water bath automatic temperature control heating device, add a predetermined amount of clean water to dilute it to the required concentration, and set aside . Add a predetermined amount of clean water and a treatment agent into a stainless steel beaker with a volume of 2 liters, add a predetermined amount of silica sol containing nano-silica during stirring, and stir evenly to form a silica sol with a desired concentration of nano-silica aqueous solution. Add the diluted natural rubber latex into the aqueous silica sol solution during stirring, heat in a water bath after stirring for 10...

example 1-1

[0046] Wet milling conditions: NR dry solid content 100g, diluted fresh natural rubber latex NR dry solid mass percentage concentration 20%; silica sol type / particle size: alkaline sodium salt / 7~9nm, alkaline sodium salt / 10nm , Alkaline monocrystalline silicon / 10nm, Alkaline sodium salt / 30nm, Alkaline ammonium salt / 5~15nm, Neutral / 8~15nm and Acidic / 10nm, the amount of silica sol converted to nano silica is 70g, silica sol SiO in aqueous solution 2 The mass percent concentration is 15%; the type / amount of treatment agent: diethylene glycol / 7g; the reaction temperature is 80°C, and the reaction time is 1 hour; the type / amount / concentration of coagulant: calcium chloride / 2.1g / 5%.

[0047] Basic vulcanization formula 1 (parts by mass): NR 100 (calculated as dry rubber), nano-silica 70, stearic acid 2.0, ZnO 5.0, accelerator DM 1.3, accelerator TT 0.2, anti-aging agent 4010NA 1.5, sulfur 2.2.

[0048] Table 1-1 is the relationship between the type of silica sol and its particle si...

example 1-2

[0052] Wet milling conditions: the amount of NR dry solids is 100g, the mass percentage concentration of NR dry solids diluted with fresh natural rubber latex is 20%; the type / particle size of silica sol: alkaline sodium salt / 7~9nm, silica sol is converted to nanometer The amount of silicon oxide is 70g, the SiO of the silica sol aqueous solution 2 Mass percent concentration 15%; treatment agent type / amount: OP-10 / 7g, AE0-9 / 7g, ethylene glycol / 7g, diethylene glycol / 7g, triethylene glycol / 7g, 1,2-propanediol / 7g , butylene glycol / 7g and neopentyl glycol / 7g; reaction temperature 80°C, reaction time 1 hour; flocculant type / amount / concentration calcium chloride / 2.1g / 5%.

[0053] Basic vulcanization formula 1 (parts by mass): NR 100 (calculated as dry rubber), nano-silica 70, stearic acid 2.0, ZnO 5.0, accelerator DM 1.3, accelerator TT 0.2, antioxidant 4010NA 1.5, sulfur 2.2.

[0054] Table 1-2 is the relationship between the type of treatment agent and the physical and mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com