Method using iodine solution to treat lithium surface and application of method to solid-state battery

A solid-state battery, metal lithium technology, used in lithium batteries, battery electrodes, secondary batteries, etc., can solve the problems of metal lithium instability, electrical contact loss, etc., and achieve the effect of good stability and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

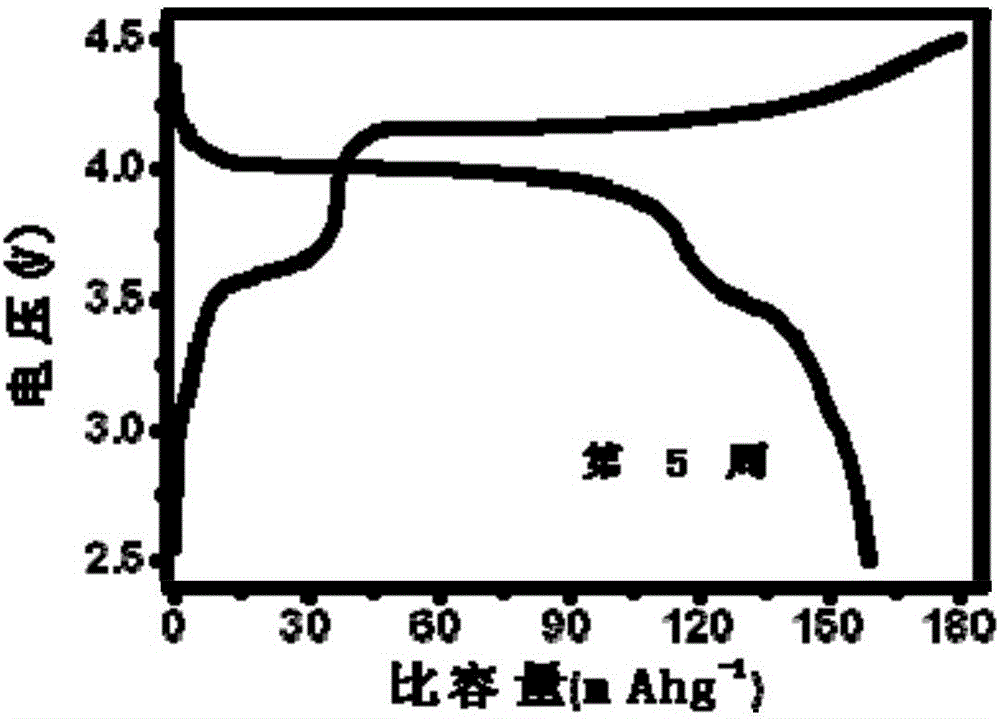

Embodiment 1

[0026] A method for treating the surface of metallic lithium with an iodine solution and its application in solid-state batteries. The assembly of solid-state batteries includes the preparation of surface-treated lithium metal electrodes, the preparation of composite solid electrolytes, the preparation of positive electrodes, and the assembly of solid-state batteries. The specific implementation process of iodine solution treatment metal lithium surface method and its application in solid-state battery is as follows:

[0027] 1. Preparation of lithium-boron alloy negative electrode treated with iodine:

[0028] The solute used in the preparation of the solution is iodine particles, and the solvent is tetrahydrofuran; the lithium negative electrode material used is a Li-B alloy sheet with a lithium content of 55%.

[0029] Concrete preparation steps are as follows:

[0030] a) Weigh 100 mg of iodine granules and place them in a reagent bottle, then add 4.9 g of tetrahydrofura...

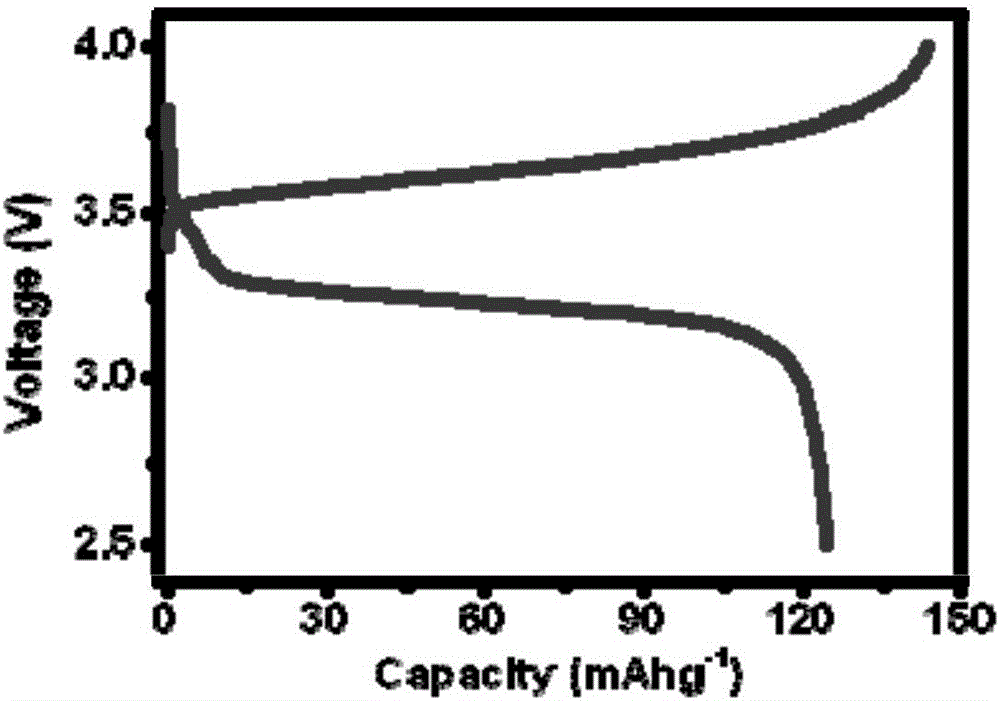

Embodiment 2

[0051] A method for treating the surface of metallic lithium with an iodine solution and its application in solid-state batteries. The assembly of solid-state batteries includes the preparation of surface-treated lithium metal electrodes, the preparation of composite solid electrolytes, the preparation of positive electrodes, and the assembly of solid-state batteries. The specific implementation process of iodine solution treatment metal lithium surface method and its application in solid-state battery is as follows:

[0052] 1. Preparation of lithium-boron alloy negative electrode treated with iodine:

[0053] The preparation method is the same as that of the surface-treated lithium metal electrode used in Example 1.

[0054] 2. Preparation of composite electrolyte:

[0055] The organic component of the composite electrolyte uses PEO as a polymer with a molecular weight of 100,000. The solvent for dissolving PEO is THF, and the electrolyte is LiTFSI. The inorganic component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com