Patents

Literature

36results about How to "Has ion conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

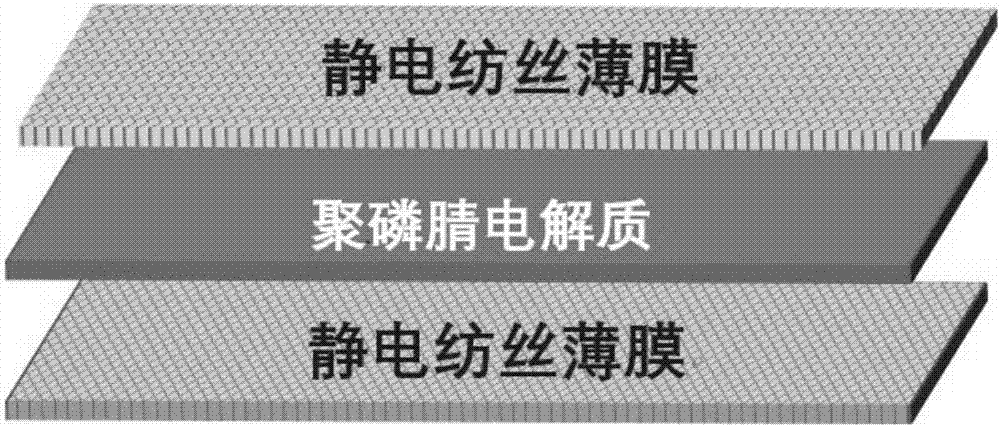

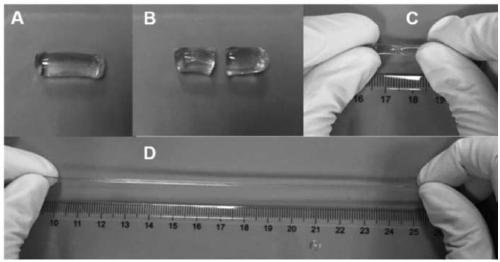

Solid electrolyte with double conducting ion networks and preparation method of solid electrolyte

ActiveCN106898811AImprove mechanical propertiesImprove film formationSolid electrolytesSecondary cellsSolid state electrolytePolyphosphazene

The invention relates to solid electrolyte with double conducting ion networks and a preparation method of the solid electrolyte, and solves the technical problem that existing polyphosphazene solid electrolyte is poor in mechanical property and low in conductivity. The solid electrolyte consists of a porous film and a polyphosphazene electrolyte material, wherein the porous film consists of a polymer, inorganic solid electrolyte and lithium salt; the porous film is a framework of the polyphosphazene electrolyte; and the polyphosphazene electrolyte is a carrier of lithium ions. The invention simultaneously provides a preparation method of the solid electrolyte. The solid electrolyte can be widely used in the field of preparation of the electrolyte.

Owner:BEIJING UNIV OF CHEM TECH

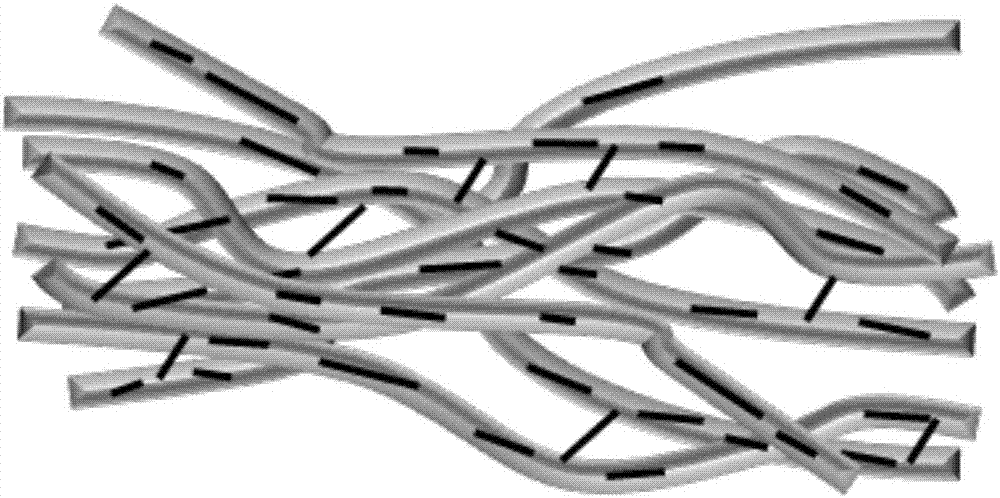

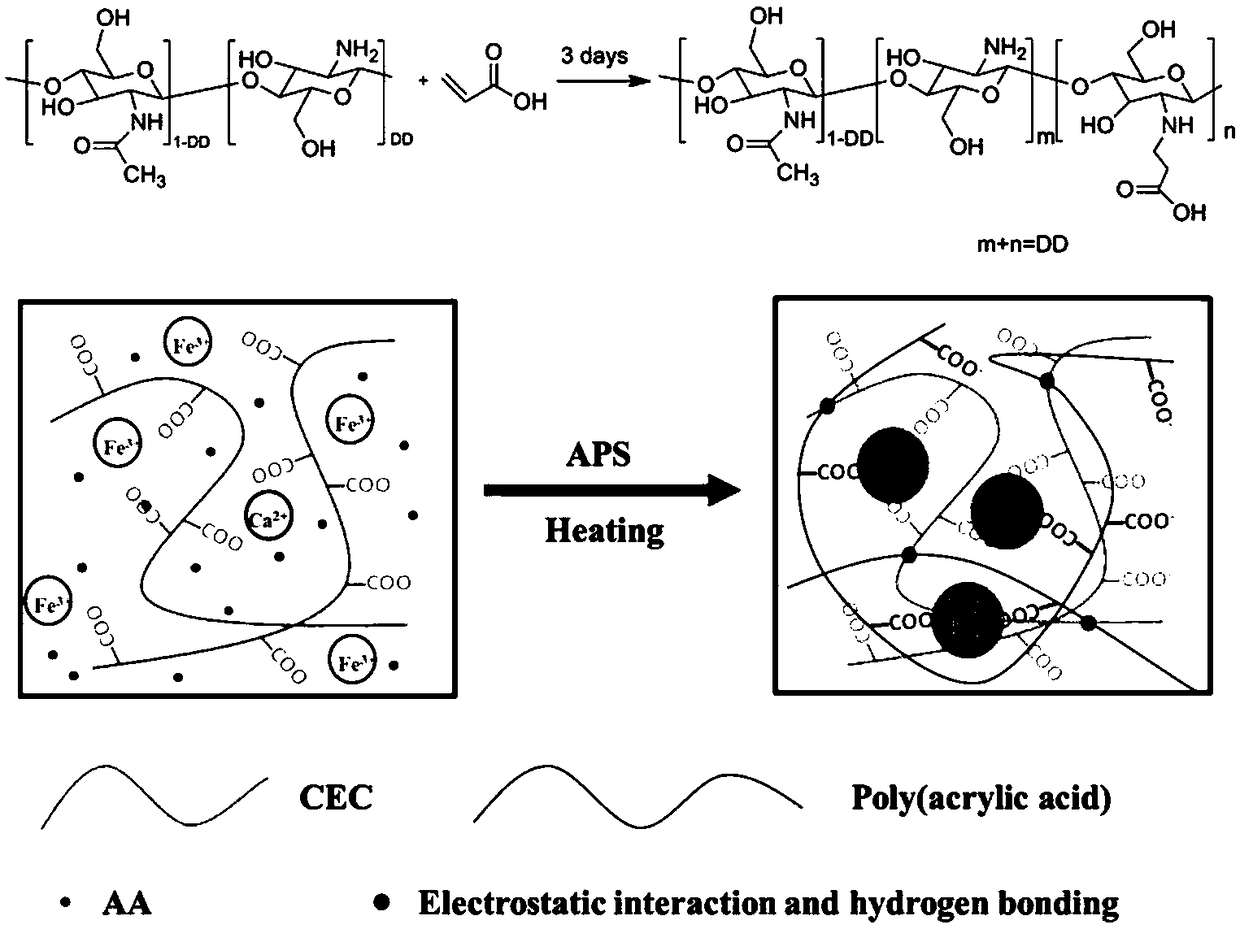

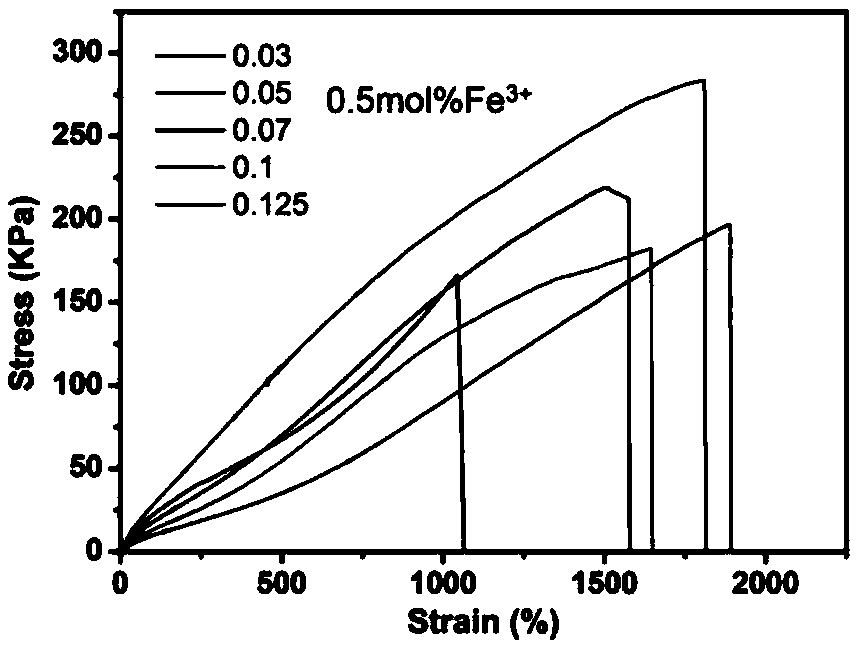

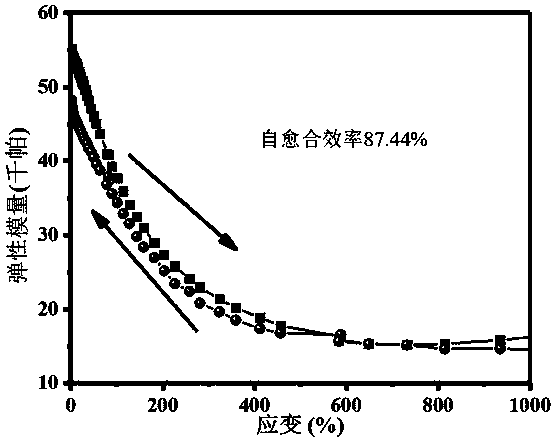

High-toughness self-repairing physical hydrogel based on dual ion coordination and preparation method thereof

ActiveCN109054051AImprove mechanical propertiesExcellent self-healing performanceSelf-healing hydrogelsNitrogen gas

The invention discloses high-toughness self-repairing physical hydrogel based on dual ion coordination and a preparation method thereof. The physical hydrogel has multi-crosslinking sites. The preparation method of the high-toughness self-repairing physical hydrogel comprises the following steps: dissolving N-carboxyethyl chitosan (CEC), acrylic acid (AA), an FeCl3 water solution and a CaCl2 watersolution into de-ionized water according to a certain ratio and carrying out ultrasonic treatment to obtain a uniform and transparent solution; then carrying out vacuum deoxygenation on the solution;adding an ammonium persulfate (APS) water solution and a catalyst N,N,N',N'-tetramethyldiethylamine (TEMED) in sequence under the protection of nitrogen gas; reacting for at least 4h under the condition of 30 to 50 DEG C, so as to prepare the physical hydrogel. The physical hydrogel provided by the invention has excellent mechanical properties and self-repairing properties; metal ions are introduced so that the gel has certain ionic conductivity; furthermore, an application range of the chitosan based self-repairing hydrogel is expanded; the high-toughness self-repairing physical hydrogel ishopefully applied to fields including wearable flexible electronic devices, soft-bodied robots, biomedicines, aerospace and the like.

Owner:ZHEJIANG UNIV

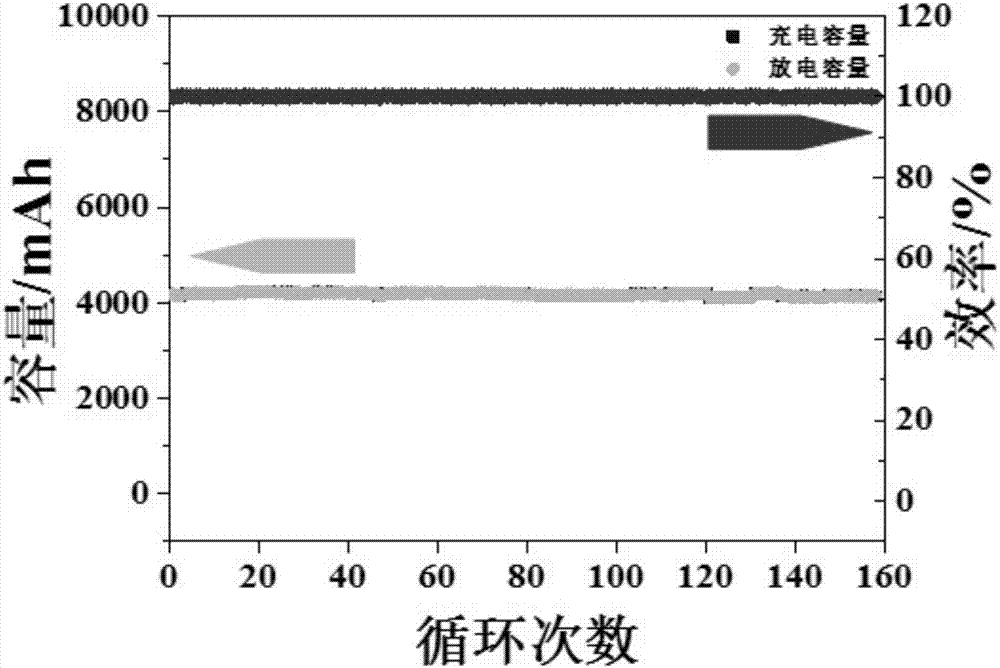

High-energy lithium battery cathode slurry and preparation method thereof

InactiveCN109888264AGood dispersionHas ion conductivityElectrode manufacturing processesSecondary cellsElectrical batteryHigh energy

The invention discloses high-energy lithium battery cathode slurry, and relates to the technical field of lithium battery production. The slurry mainly aims at solving the problems that the existing cathode slurry has poor viscosity, has insufficiently uniform smearing, and has a direct influence on the performance of a battery. The slurry comprises the following raw materials: a cathode active substance, a conductive agent, an adhesive agent, a defoaming agent, a high-polymer additive, a dispersing additive, a thickening agent, a flame retardant, a buffer solution and the balance of solvent.The invention further discloses a preparation method of the high-energy lithium battery cathode slurry. The high-polymer additive has ionic conductivity, so that the ionic conductivity of a cathode material can be improved; the charge transfer resistance can be reduced; and the rate capability of a lithium ion battery can be improved. The thickening agent is added by combination, so that various components can fully exert effects; the thickening agent can keep the stability of a molecular structure in a long-time standing process, and can keep the performance of the slurry stable; and agglomeration and sedimentation can be avoided.

Owner:山东高质新能源检测有限公司

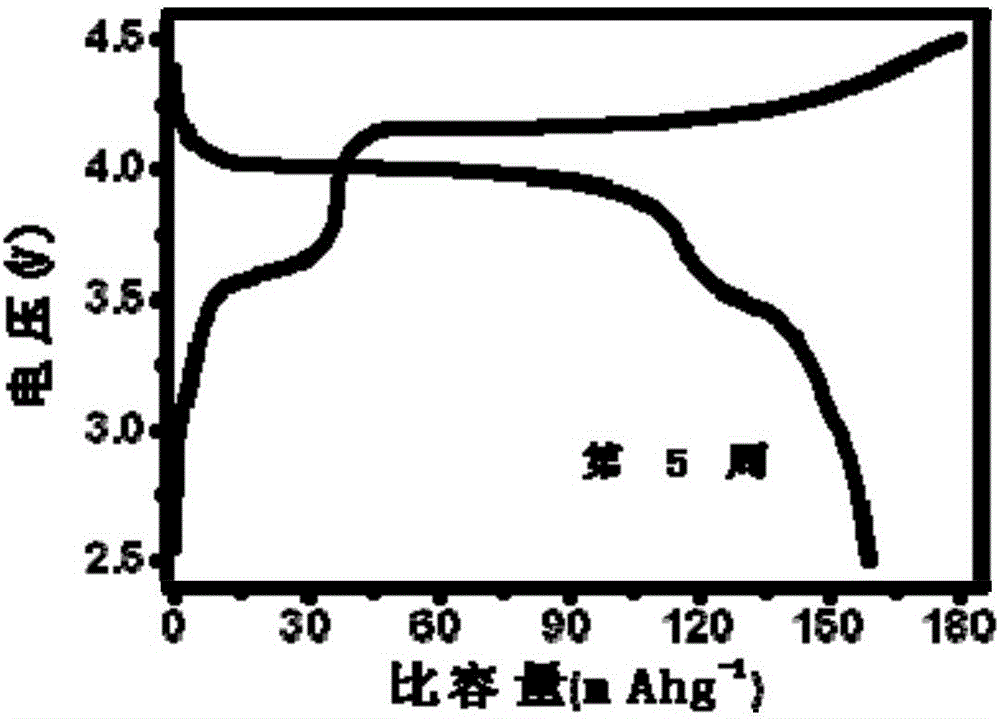

Method using iodine solution to treat lithium surface and application of method to solid-state battery

InactiveCN106784636AGood stability and compatibilityHas ion conductivityChemical electrode manufacturingLi-accumulatorsBatch processingIodine solutions

The invention relates to a method using an iodine solution to treat a lithium surface and application of the method to a solid-state battery and belongs to the technical field of chemical power supplies. The method is characterized in that cathode materials used during lithium electrode production are pure lithium or boron alloy sheets and are cut and pressed into an electrode plate; a solvent for dissolving iodine is tetrahydrofuran, and the weight percentage concentration of the iodine solution is 0.5-30%; the electrode plate is submerged into the iodine solution, and residual liquid is dried through drying to obtain the surface-treated lithium cathode plate. The application of the method to the solid-state battery is characterized in that solid-state battery assembling includes preparing the surface-treated lithium cathode, preparing composite solid electrolyte, preparing an anode and assembling the solid-state battery, and the surface-treated lithium cathode preparation uses the method. The method is simple, evident in effect, applicable to the large-scale and batch processing of lithium cathode surfaces, and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

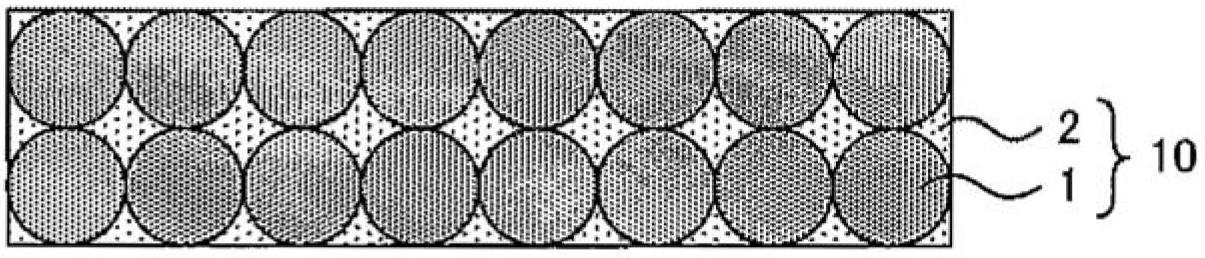

High-safety lithium ion battery anode material and preparation method thereof

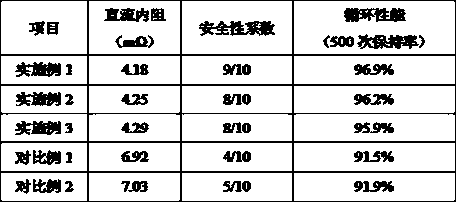

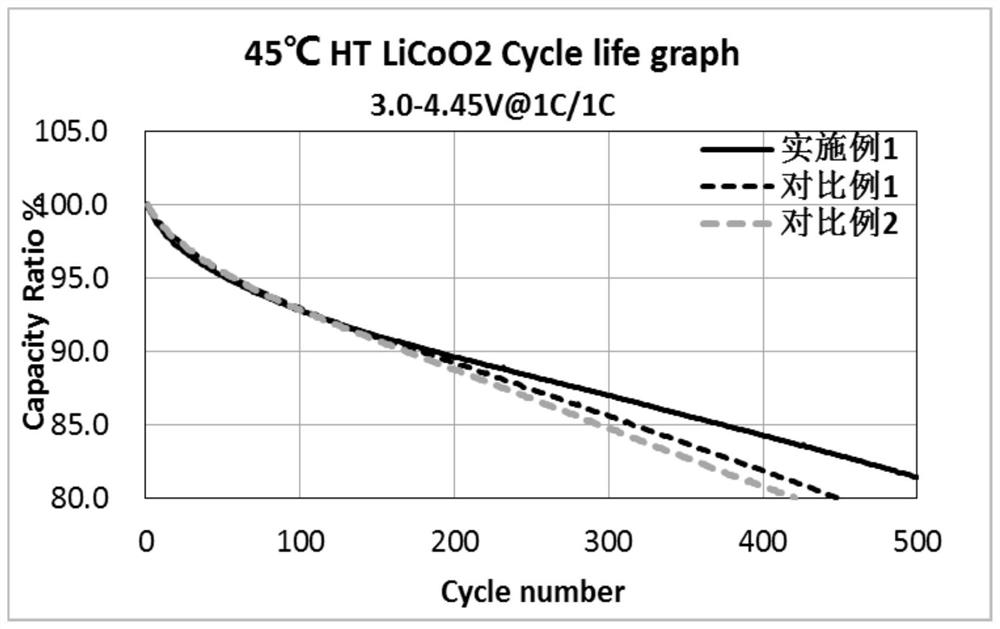

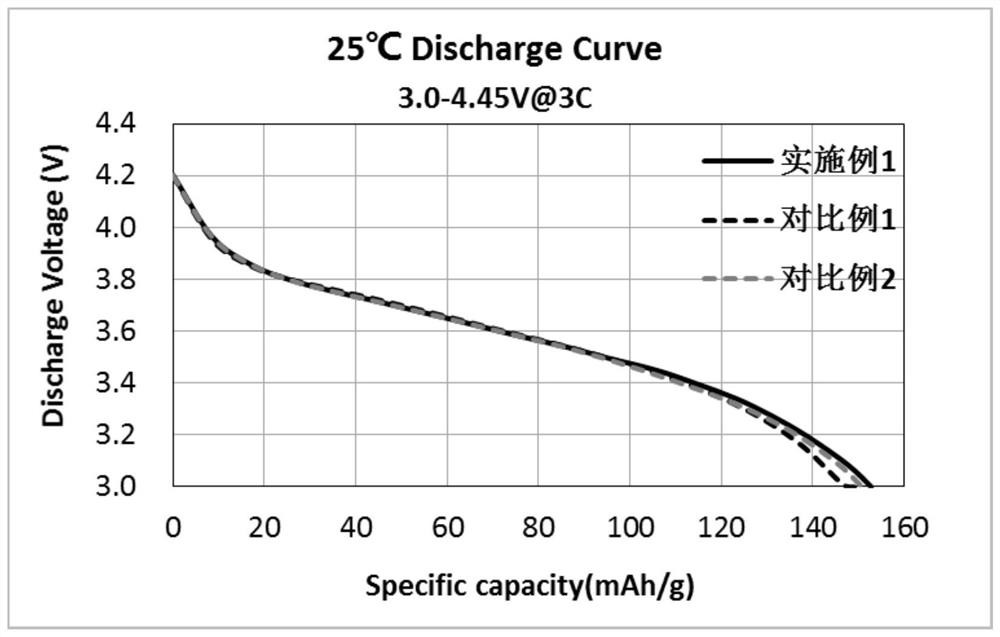

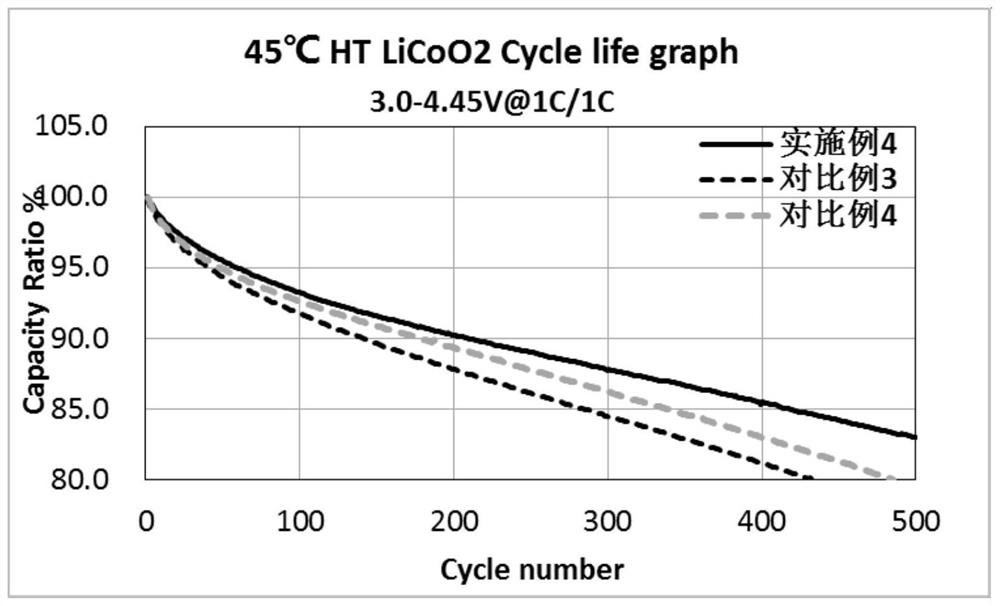

The invention discloses a high-safety lithium ion battery anode material and a preparation method thereof and relates to the field of preparation of battery materials, in particular to the field of ananode material of lithium ion batteries. The anode material is characterized by consisting of a core, a middle layer and an outer layer and adopts a core-shell structure; the middle layer consists ofa functional compound containing nitrogen or phosphorus and a binder; the outer layer consists of asphalt, lithium metaaluminate, carbon nanotubes and a binder. The defects of the lithium ion batteries in the safety performance at present are overcome, the safety performance of the material is improved through coating modification of the material surface, and meanwhile, the rate performance and cycle performance of the material are both considered.

Owner:内蒙古欣源石墨烯科技股份有限公司

Lithium-ion battery positive pole piece and preparation method thereof

InactiveCN112151807AImprove thermal stabilityImprove high temperature cycle life and high temperature storage capacity retentionElectrode carriers/collectorsElectrode collector coatingElectrically conductiveOrganosolv

The invention discloses a lithium-ion battery positive pole piece which comprises a current collector and a positive active material layer coating the surface of the current collector, the positive active material layer mainly comprises a positive active material, a conductive agent, additives and a binder, and the additives are aluminum phosphate and lithium phosphate. The preparation method comprises the following steps: (1) uniformly mixing the positive electrode active material, the binder, the conductive agent, the aluminum phosphate, the lithium phosphate and an organic solvent to obtainpositive electrode slurry; and (2) coating the surface of the current collector with the positive pole slurry, and drying to obtain the positive pole piece of a lithium-ion battery. The aluminum phosphate and the lithium phosphate are introduced into the positive active material layer of the positive pole piece of the lithium-ion battery at the same time to serve as the additives, and the comprehensive electrical properties such as high-temperature cycle, high-temperature storage performance and rate capability of the battery are synergistically improved.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

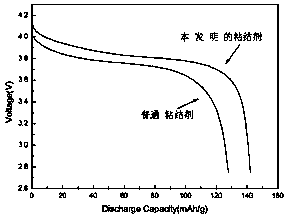

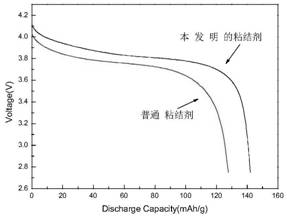

Cathode slurry of lithium ion batteries on production line and preparation method of cathode slurry

InactiveCN107394187AIncrease productivityImprove conductivityElectrode manufacturing processesSecondary cellsDispersityProduction line

The invention belongs to the technical field of lithium ion batteries and particularly relates to cathode slurry of the lithium ion batteries on a production line and a preparation method of the cathode slurry. The cathode slurry comprises 179 parts of cathode active substance, 4 parts of conductive agent and 17 parts of lithium polyacrylate, wherein the lithium polyacrylate is used as the adhesive. Compared with a traditional adhesive, the lithium polyacrylate has ionic conductivity and can integrally the conductivity of the cathode slurry. The cathode slurry is prepared by a subsection ball milling method, the materials are sufficiently stirred to avoid slurry settling, and accordingly the dispersing performance of the cathode slurry is increased greatly. The cathode slurry has the advantages that the cathode slurry is good in dispersity, moderate in viscosity, good in conductivity, low in cost, green, environmentally friendly and widely applicable to the production line for producing lithium ion batteries, the process of the cathode slurry is optimized, and the production efficiency of the lithium ion batteries can be increased while the overall performance of the produced lithium ion batteries can be increased.

Owner:GUANGDONG UNIV OF TECH

Normal-temperature molten salt, electrode, cell, agent for preventing charge-up, and method for observing sample

ActiveCN102656150AImprove ionic conductivityTo prevent cut-offFuel and primary cellsOrganic chemistryHalogenMolten salt

The invention relates to a normal-temperature molten salt, an electrode, a cell, an agent for preventing charge-up, and a method for observing sample. An object of the present invention is to provide an ambient temperature molten salt having excellent electron conductivity in addition to ion conductivity. The present invention attains the object by providing an ambient temperature molten salt comprising a first imidazolium salt having a cationic segment represented by the general formula (1) and an anionic segment represented by MX 4 (where M is a transition metal and X is a halogen); and a second salt having a cationic segment as a monovalent cation and an anionic segment as a halogen.

Owner:TOYOTA JIDOSHA KK

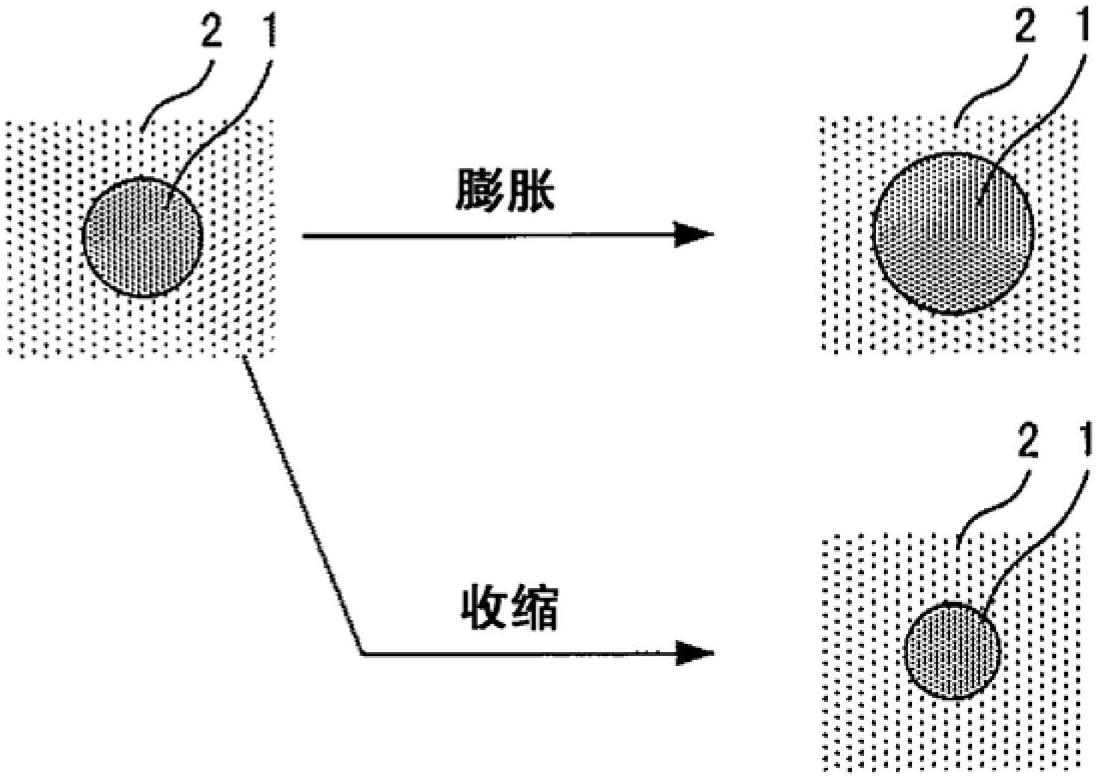

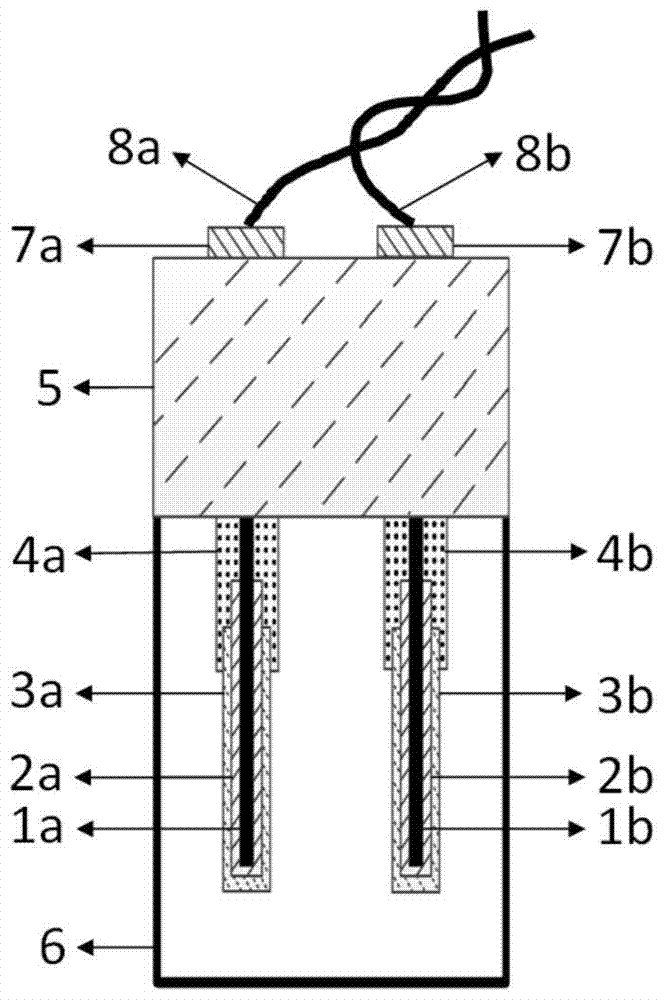

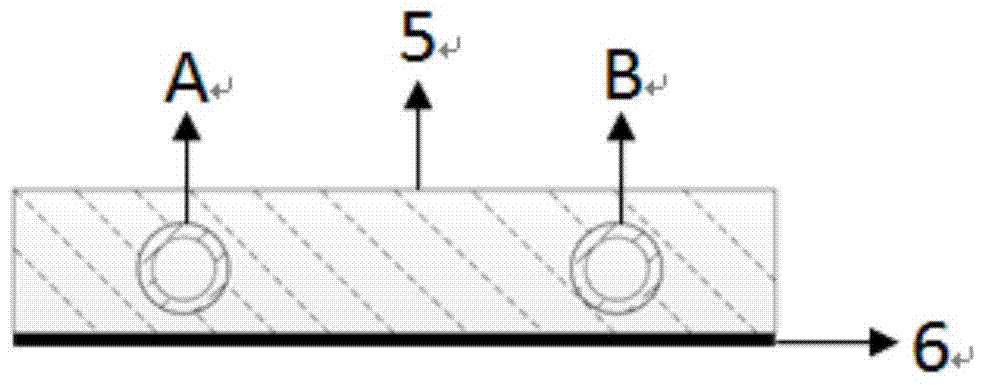

Composite binder for solid-state lithium batteries and preparation method thereof

ActiveCN109860595AHas ion conductivityImprove adhesionNon-macromolecular adhesive additivesCell electrodesOrganic solventElectrical conductor

The invention discloses a composite binder for solid-state lithium batteries and a preparation method thereof. The compound binder consists of a high-molecular polymer, lithium salt and an inorganic ceramic fast ion conductor; and the preparation method is to use an organic solvent to dissolve the high-molecular polymer, the lithium salt and the inorganic ceramic fast ion conductor, and generate the organic-inorganic composite binder complexed with the lithium salt and the inorganic fast ion conductor under a certain temperature and stirring. The binder has strong cohesive and adhesive force and high ionic conductivity, and can be used for the preparation of positive and negative pole pieces of solid-state lithium batteries, so that the internal resistance of the pole pieces can be reduced, and the rate performance and cycle life of the solid-state lithium batteries can be enhanced.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

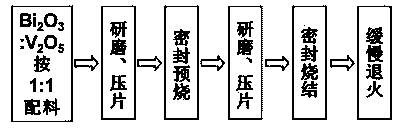

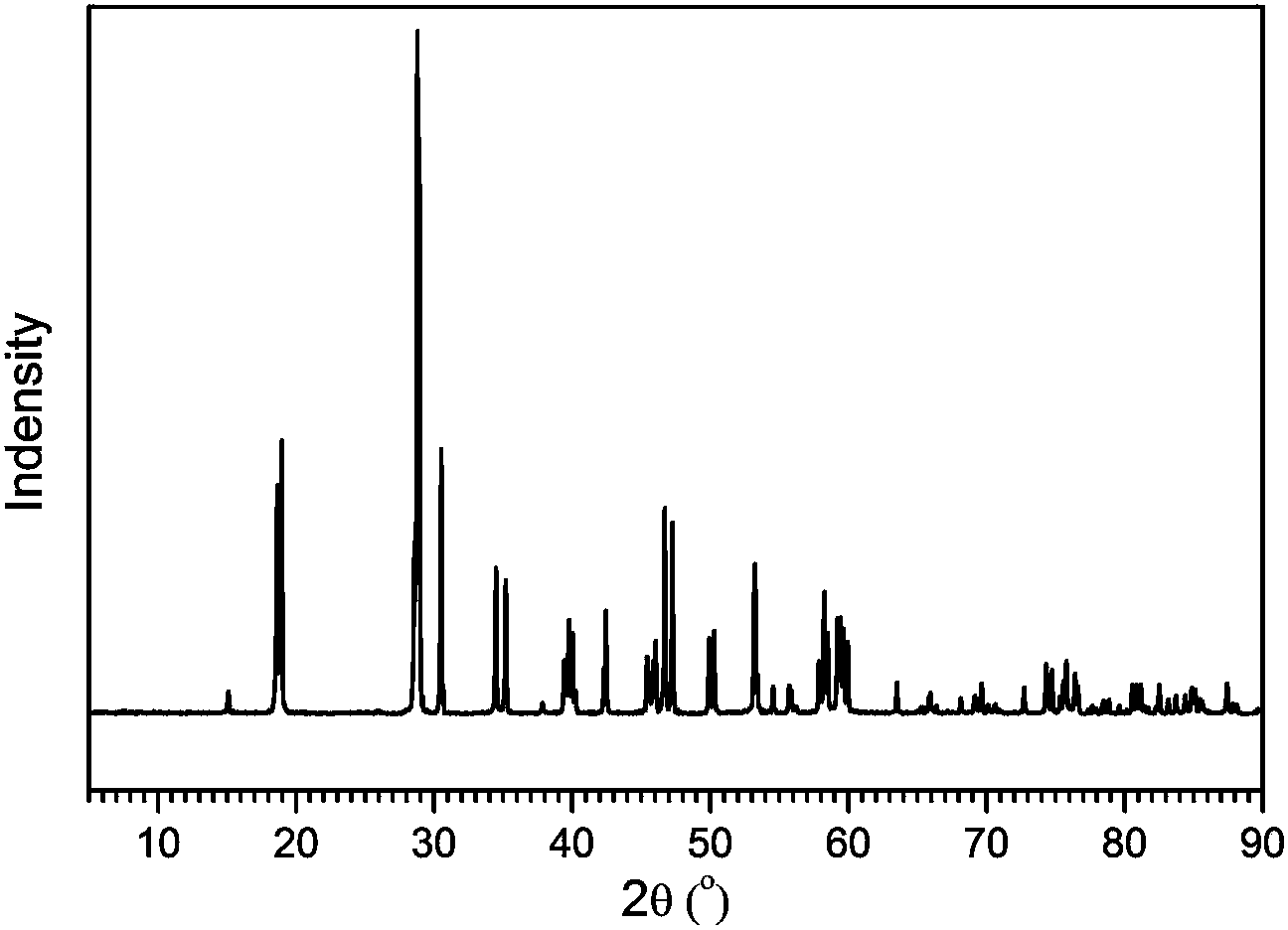

Bismuth vanadate functional ceramic and preparation method thereof

The invention relates to a bismuth vanadate functional ceramic and a preparation method thereof. For the bismuth vanadate functional ceramic, the chemical component is BiVO4, the compactness is more than 97%, the dielectric constant is 60 and the dielectric loss is less than 0.005. The preparation method of the bismuth vanadate functional ceramic comprises the following steps: by taking Bi2O3 and V2O5 powder as raw materials, mixing and preforming the raw materials, putting in a closed mold, and carrying out primary sintering; after sintering is completed, grinding into powder and preforming again; then putting into the closed mold again and carrying out secondary sintering; after the sintering is completed, controlling the cooling speed to be less than or equal to 3.3 DEG C / min, and cooling to room temperature so as to obtain the bismuth vanadate functional ceramic.

Owner:CHEM & CHEM ENG GUANGDONG LAB

Preparation method of polydopamine-coated sodium ion battery positive electrode material

PendingCN114204028AImprove cycle performancePlay a protective effectSecondary cellsPositive electrodesElectrolytic agentPhysical chemistry

A preparation method of a polydopamine-coated sodium ion battery positive electrode material comprises the following steps: 1, preparing an MxFeyMnz (OH) 2 precursor through a coprecipitation method, 0 < x < = 0.5, 0 < = y < = 0.33, 0 < z < = 0.5, x + y + z = 1, and M is a transition metal ion; 2, mixing the precursor and a sodium source according to a molar ratio of 1: (1-1.1); the preparation method comprises the following steps: mixing the raw materials, sintering at a high temperature of 850-1100 DEG C for 10-20 hours to obtain the positive electrode material with the general formula of NaaMxFeyMnzO2, and a is more than 0.67 and less than 1.1; 3, adding the positive electrode material into the dispersing solvent, stirring and dispersing to obtain a first turbid liquid, and enabling the concentration of the positive electrode material in the first turbid liquid to be 0.1-0.5 g / mL; when the pH value of the first suspension is stabilized at 8-12, adding dopamine hydrochloride, and reacting for 10-30 hours at normal temperature and normal pressure in a dry environment to obtain a second suspension; and 4, filtering, washing and drying the second suspension to obtain the polydopamine-coated sodium ion battery positive electrode material. The coating layer is high in uniformity and excellent in storage performance in air, the thickness of the polymer coating layer is adjustable, the side reaction of the positive electrode material in electrolyte can be effectively inhibited in the circulation process, and the circulation stability of the sodium ion battery is improved.

Owner:南通金通储能动力新材料有限公司

Material applicable to anode bonding and preparation method thereof

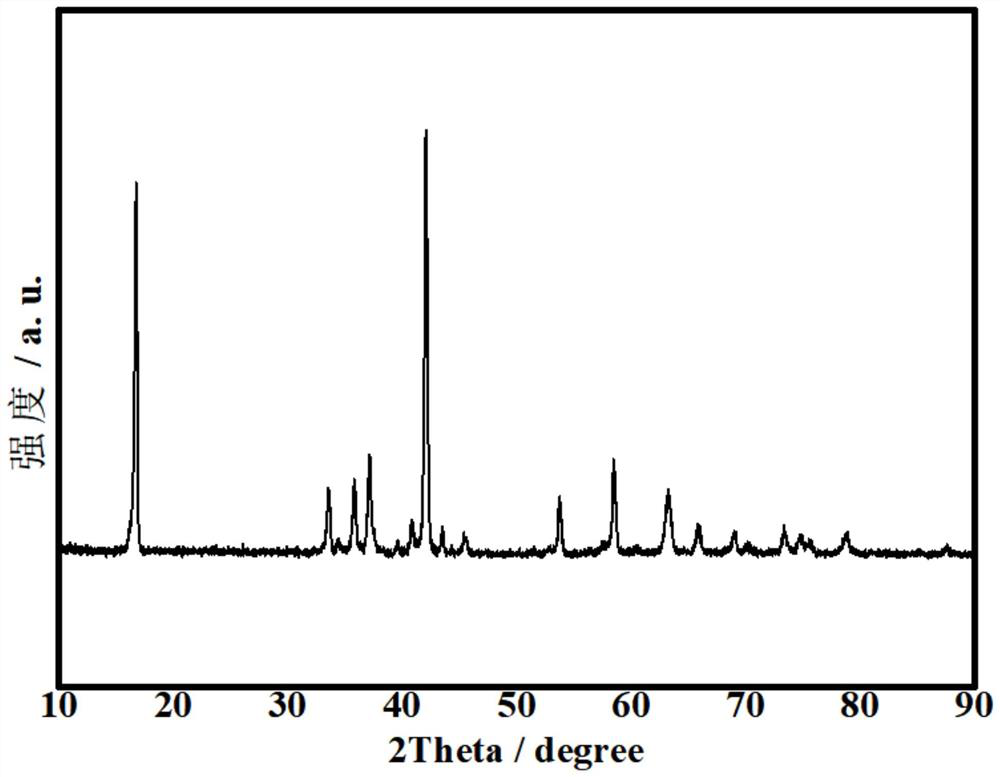

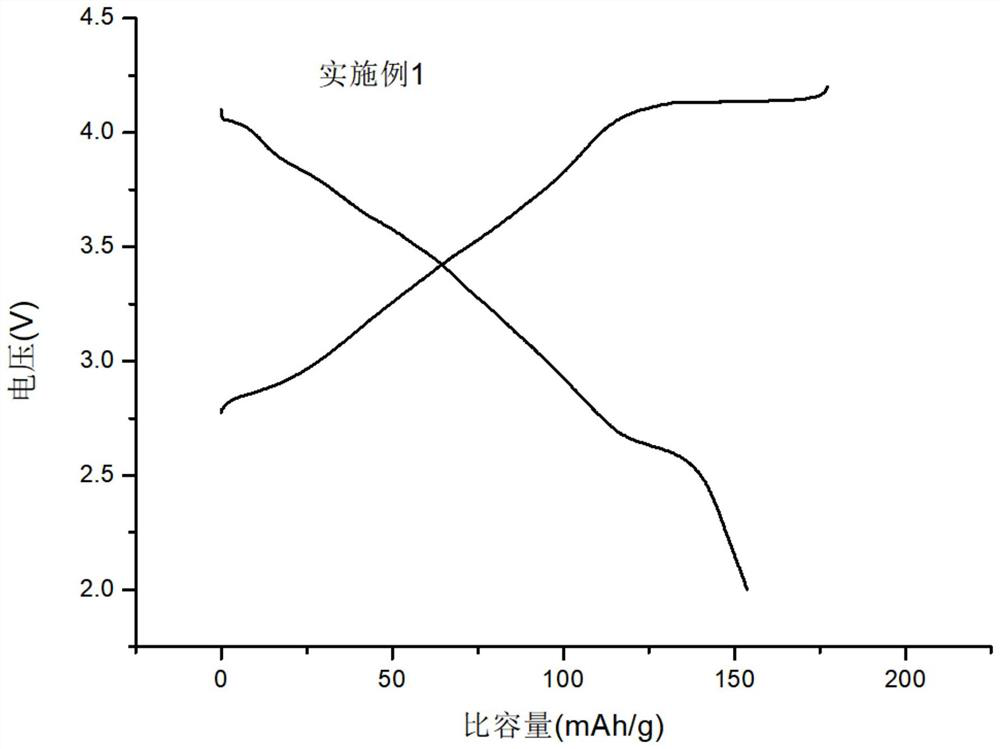

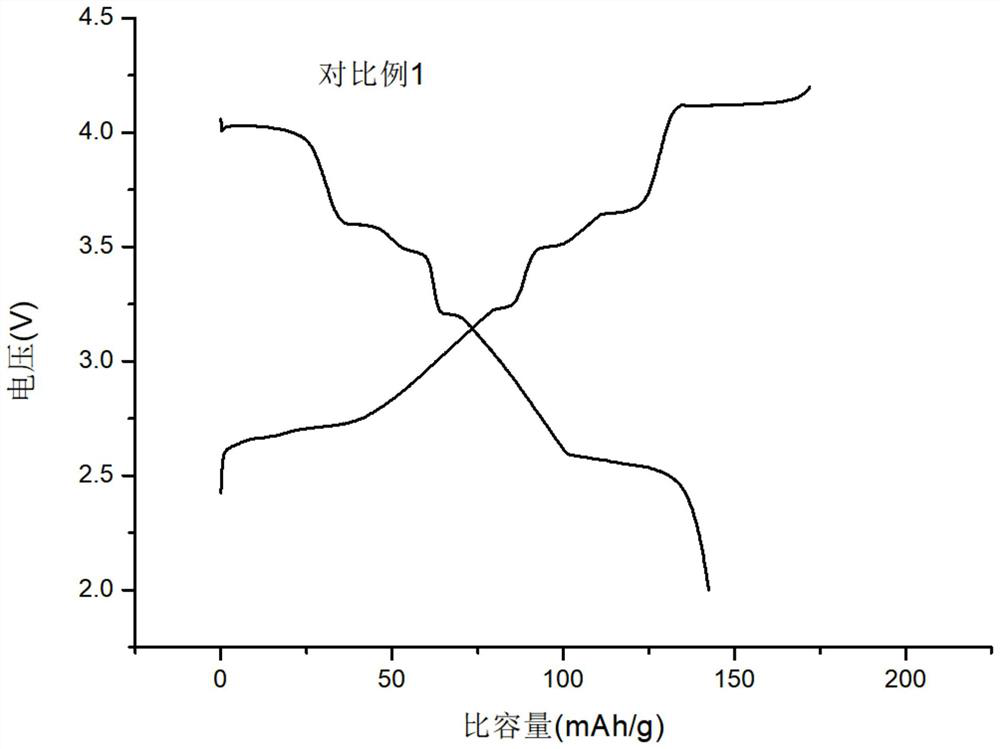

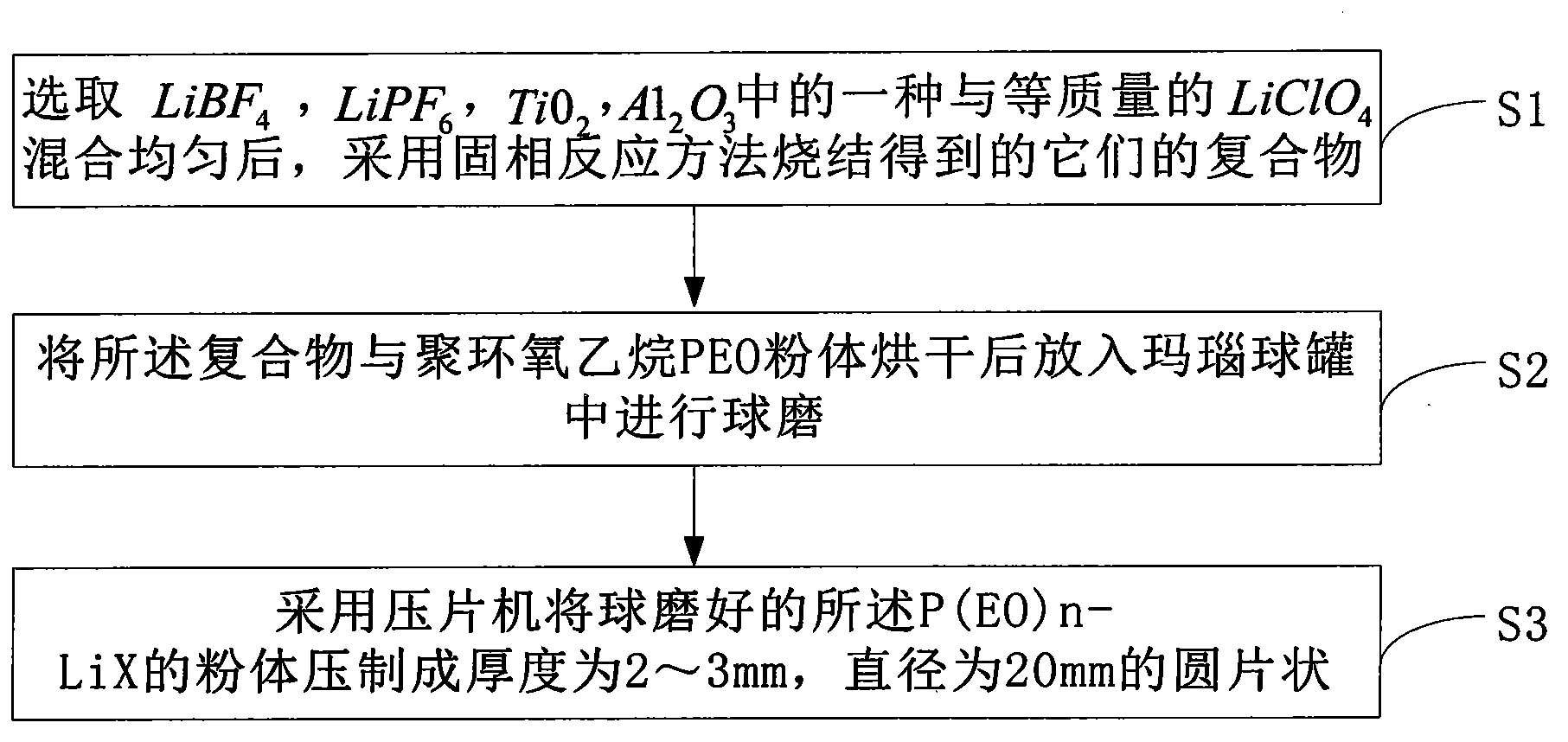

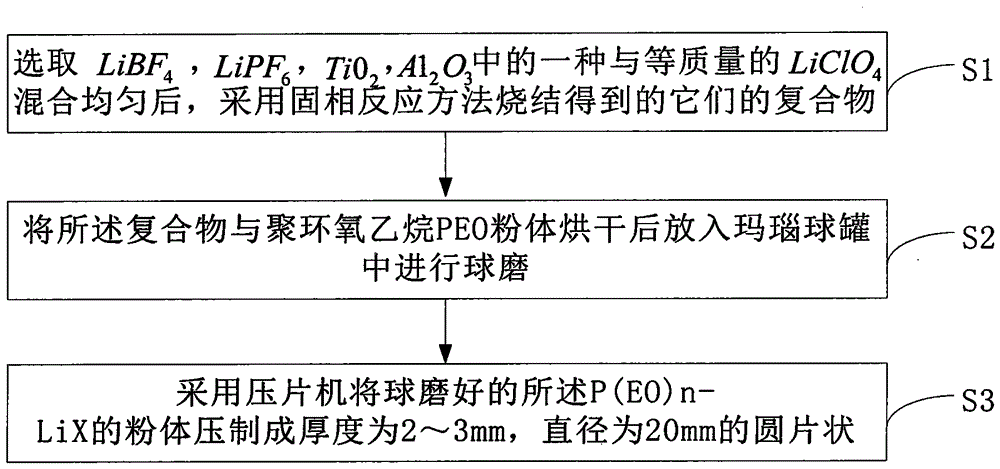

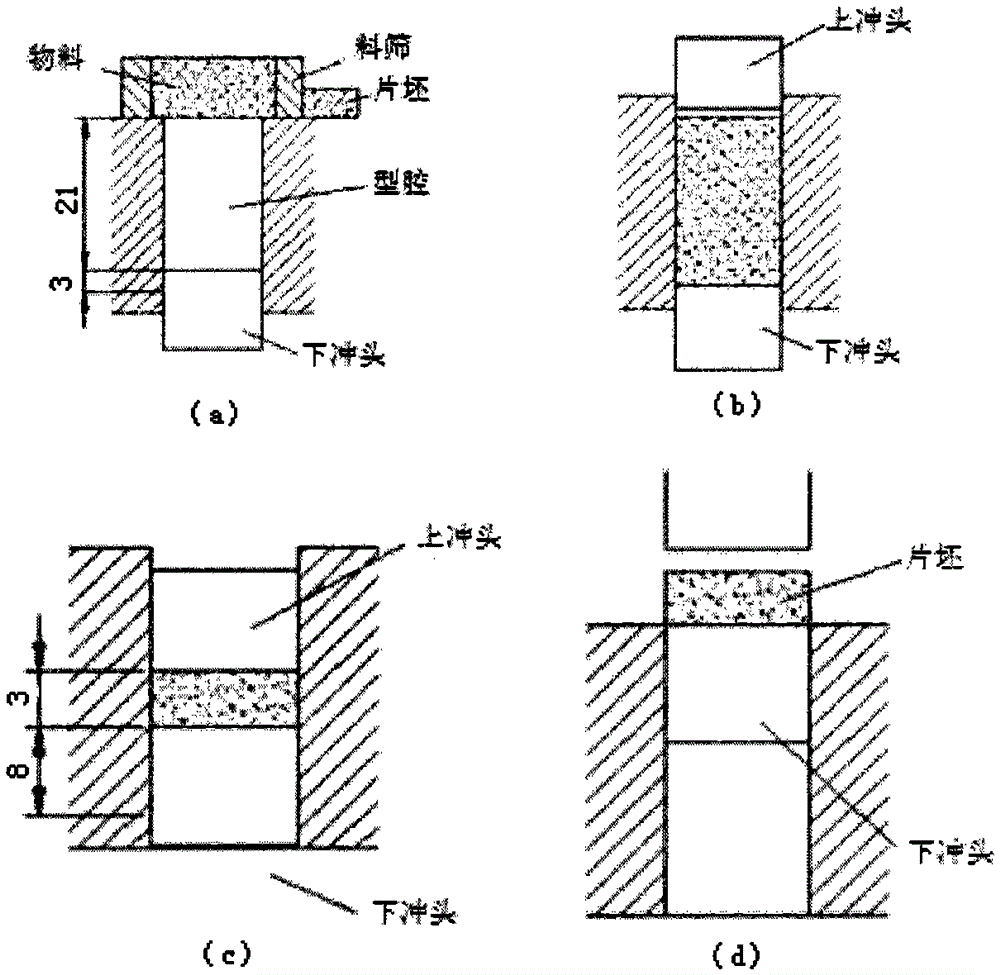

The embodiments of the invention provide a material applicable to anode bonding and a preparation method thereof and relate to the field of material preparation. Due to the application of the material, the preheating temperature during anode bonding encapsulation can be lowered, the residual stress of sealing can be reduced, and the quality of microelectronic device encapsulation is improved. The preparation method comprises the steps: uniformly mixing one of LiBF4, LiPF6, TiO2 and Al2O3 and an equal amount of LiClO4, and sintering by adopting a solid-phase reaction method, so as to obtain a complex; and baking the complex and polyethylene oxide (PEO) powder, and then, putting into an agate ball tank for ball milling, thereby preparing the macromolecular solid electrolyte material applicable to anode bonding.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

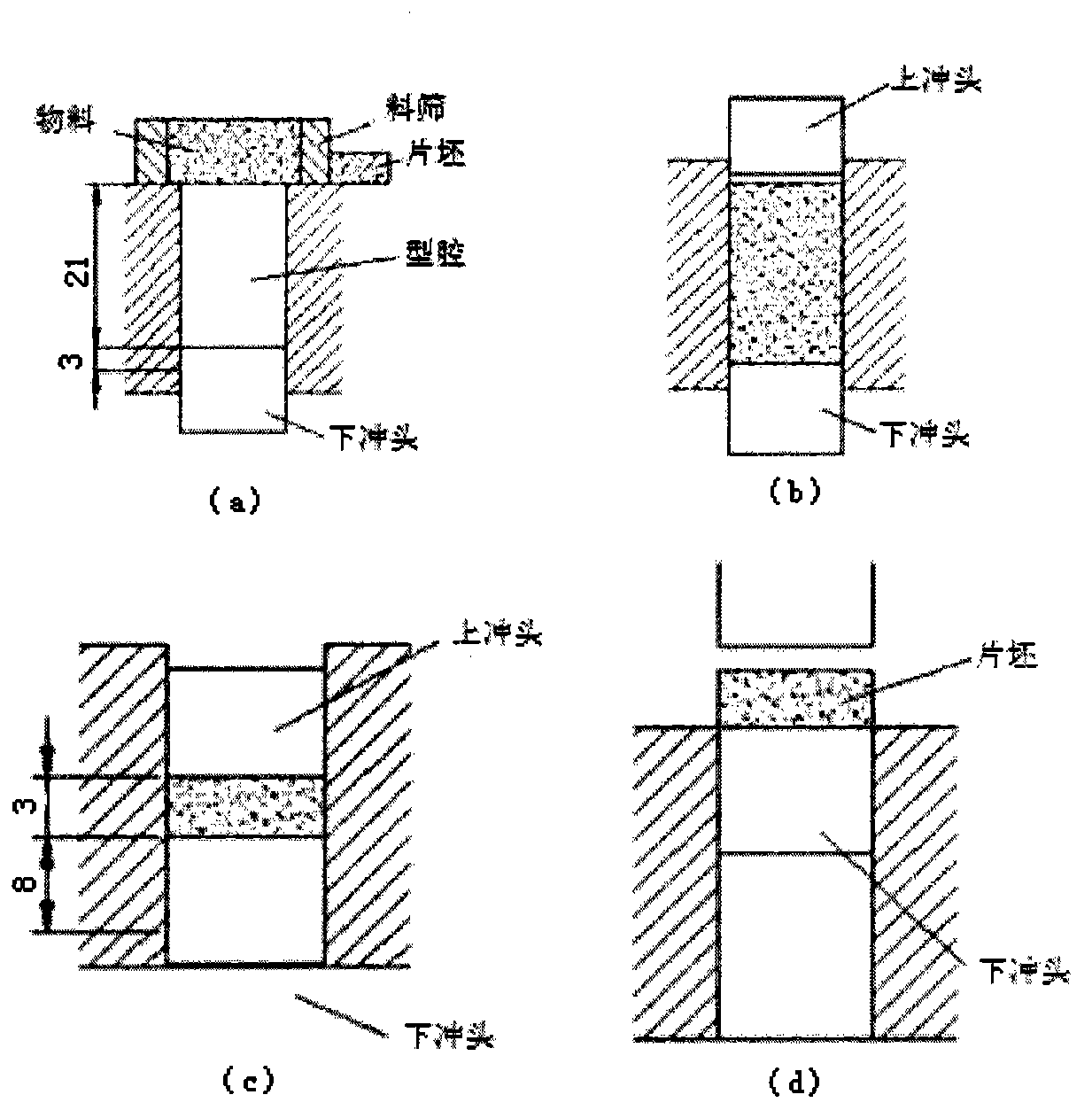

Preparation method of polyacrylonitrile/ionic liquid/polyaniline conducting composite material

The invention discloses a preparation method of a polyacrylonitrile / ionic liquid / polyaniline conducting composite material, which comprises the following steps: (1) adding aniline into 1-butyl-3-methylimidazolyl hexafluorophosphate, and stirring uniformly to obtain a mixed liquid; (2) putting polyacrylonitrile powder into a high-speed mixer, slowly adding the mixed liquid in the step (1), and stirring for 1-3 hours to obtain a mixture; (3) putting the mixture in the step (2) into a mold, and carrying out hot pressing in a flat vulcanizing bed for 10-30 minutes to obtain a polyaniline-monomer-containing polyacrylonitrile sheet; and (4) immersing the sheet in the step (3) into an acid-doped water solution, reacting for 2-10 hours, cleaning the material with water after the reaction finishes, and drying to obtain the polyacrylonitrile / ionic liquid / polyaniline composite conducting material. According to the method, the aniline and ionic liquid plasticizer 1-butyl-3-methylimidazolyl hexafluorophosphate are blended to synergically plasticize the polyacrylonitrile, and then, melting is performed to prepare the product.

Owner:ZHONGYUAN ENGINEERING COLLEGE

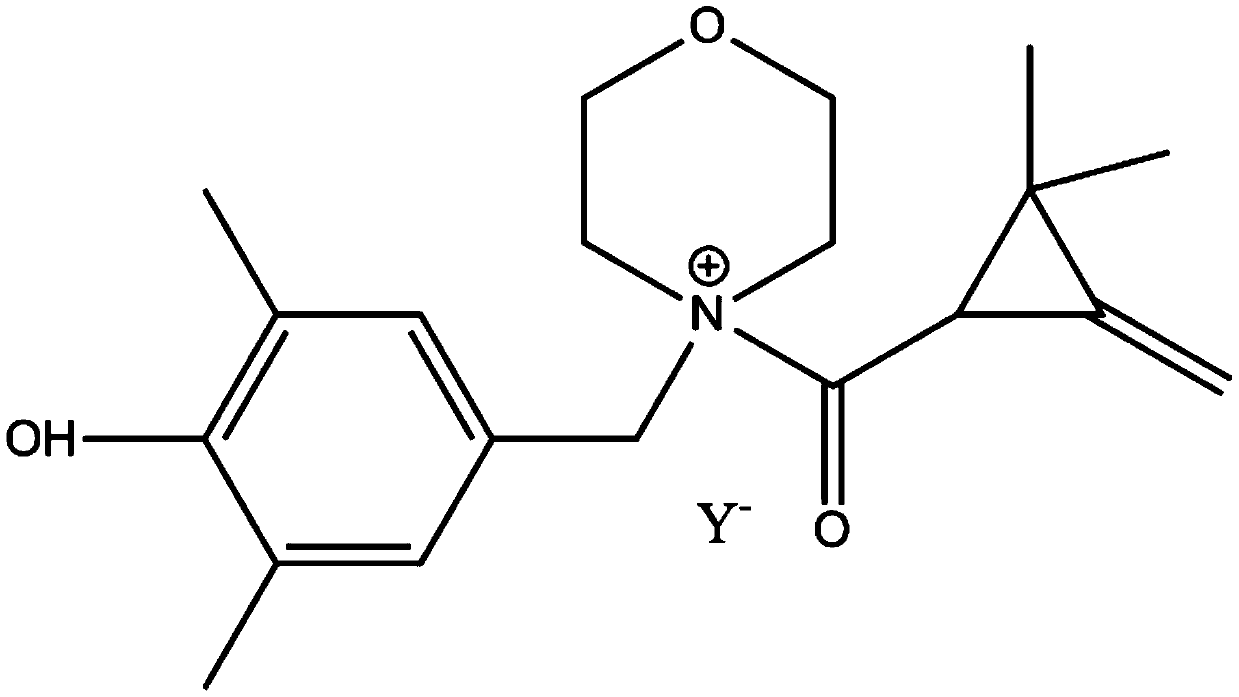

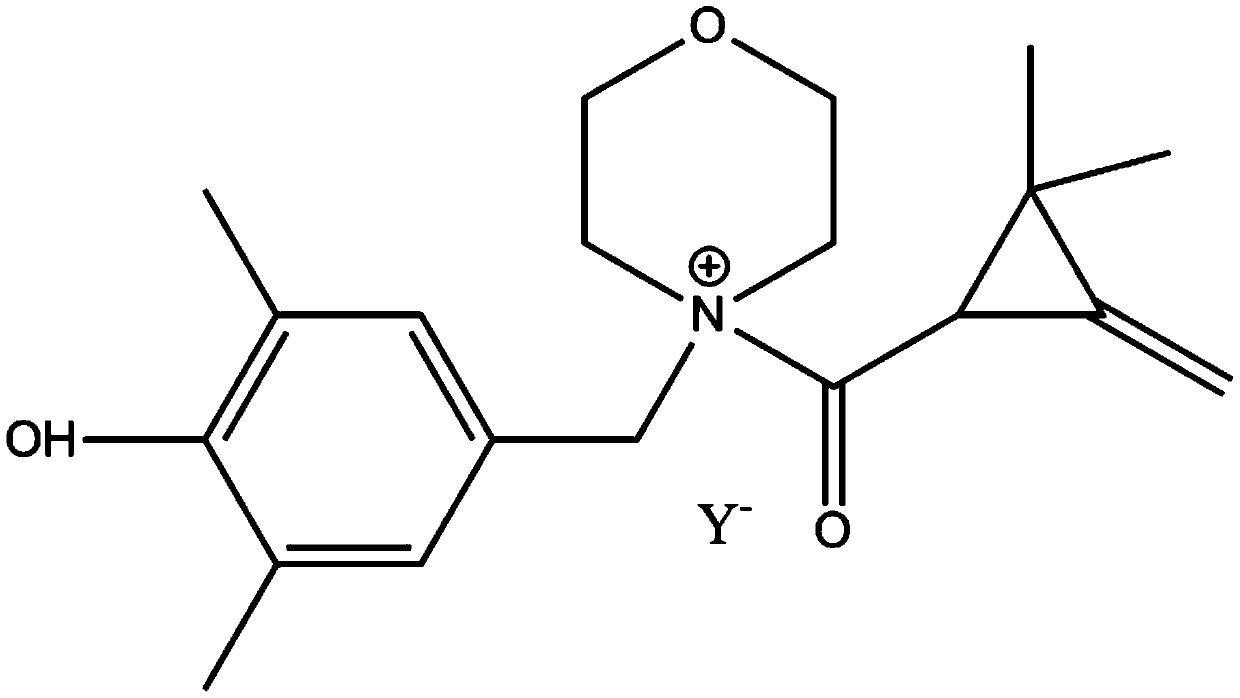

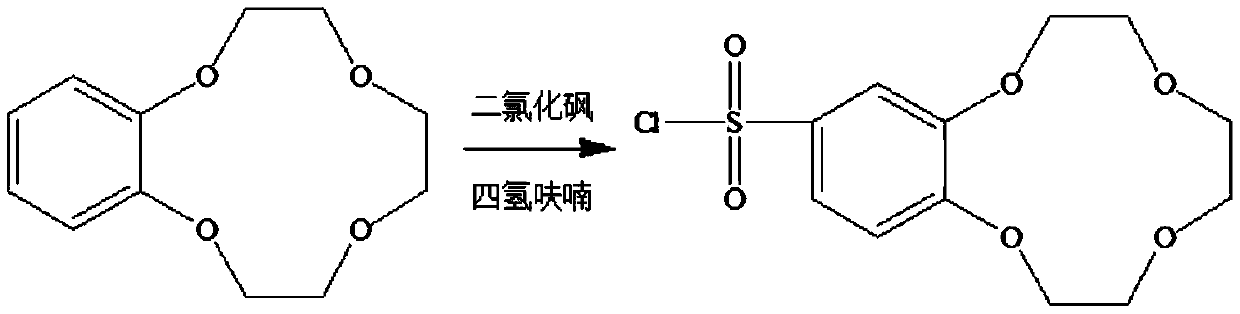

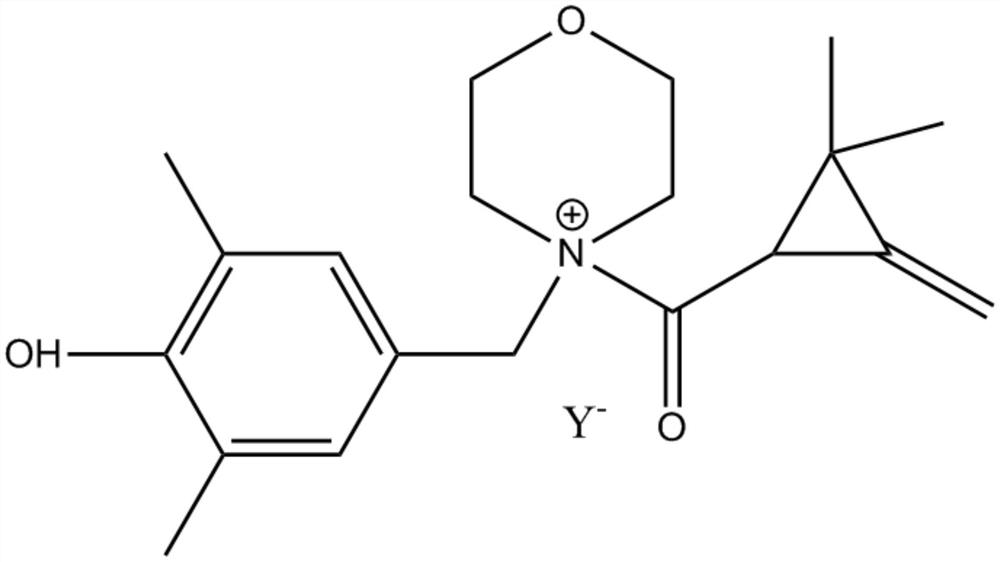

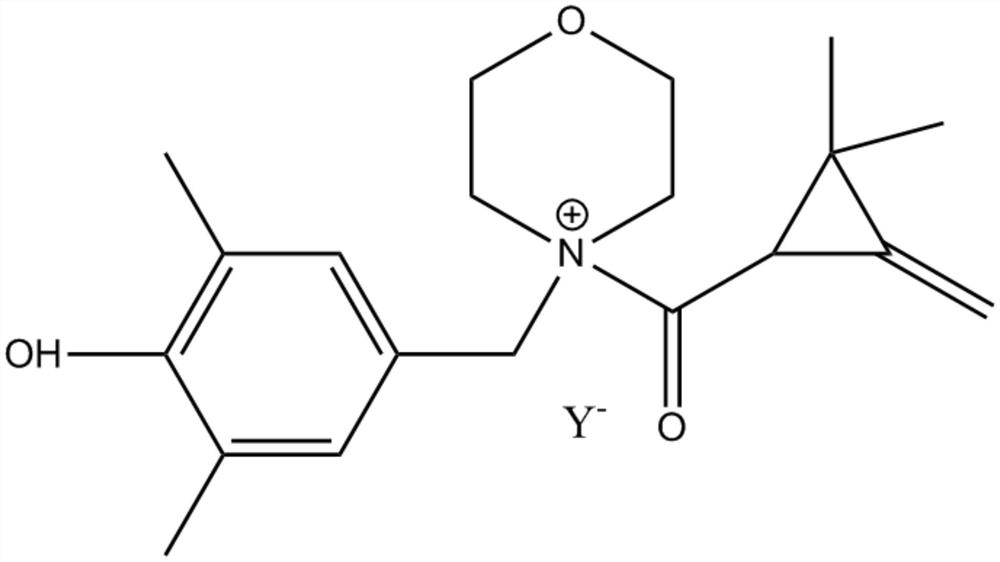

Multifunctional lubricating oil additive and application thereof

ActiveCN110423639AImprove anti-wear performanceIntermolecular tightnessOrganic chemistryAdditivesMorpholineOil additive

The invention discloses a multifunctional lubricating oil additive. The multifunctional lubricating oil additive is prepared from the following raw materials in part by weight: 50-100 parts of morpholine ionic liquid, 0.8-7.5 parts of a clearing agent, 1.2-2.6 parts of an antirust agent, 7-16 parts of an antioxidant and 0.2-3.8 parts of a foam inhibitor. The multifunctional lubricating oil additive is applied to a steel / steel or steel / aluminum friction pair, thus the antifriction and abrasion-resistant performance of the lubricating oil additive in the friction pair is significantly improved,meanwhile, the extreme pressure bearing performance of the lubricating oil additive is improved, and the friction pair is small in loss and long in service life.

Owner:广东顺德菲尔特润滑科技有限公司

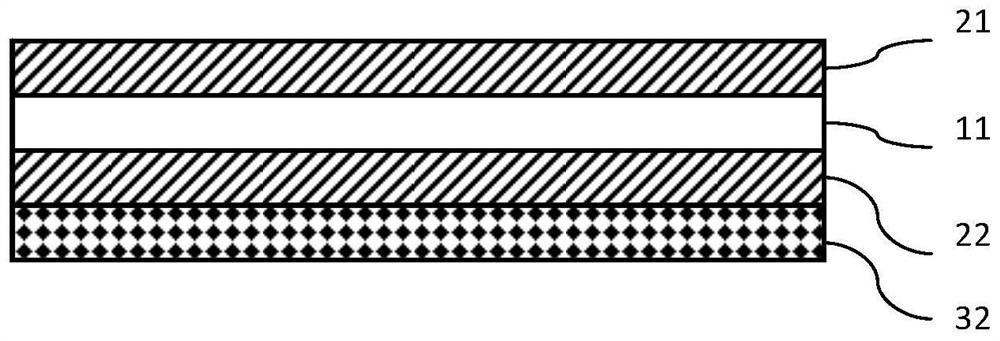

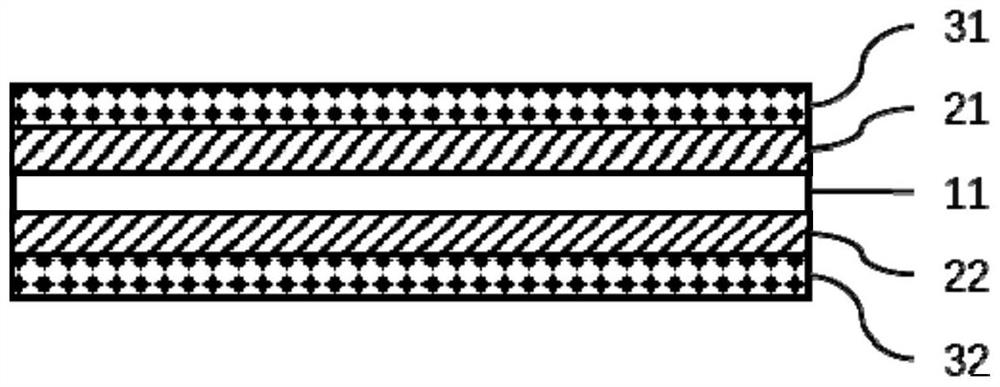

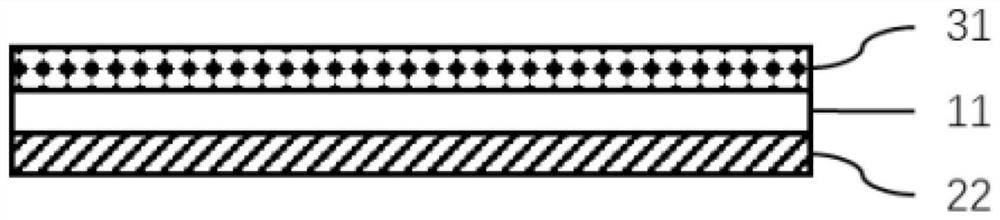

Lithium battery composite diaphragm as well as preparation method and application thereof

PendingCN114464960AImprove stabilityImproved magnification performanceLi-accumulatorsCell component detailsSolid state electrolyteElectrical battery

The invention discloses a lithium battery composite diaphragm as well as a preparation method and application thereof. The lithium battery composite diaphragm comprises a base membrane and an oxide solid electrolyte coating layer, the oxide solid electrolyte coating layer comprises oxide solid electrolyte particles. The preparation method comprises the following steps: adding a dispersing agent into a solvent, fully stirring, adding oxide solid electrolyte particles, uniformly grinding to prepare slurry A, continuously adding a thickening agent, a binder and a wetting agent, and fully stirring to prepare slurry B; and coating a base membrane with the slurry B, baking to form an oxide solid electrolyte coating, and rolling to obtain the composite diaphragm. The surface of the base membrane is coated with the oxide solid electrolyte layer to form the composite diaphragm, and the composite diaphragm is adopted during battery assembly, so that the safety performance and the electrochemical performance of the battery can be improved at the same time.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD +1

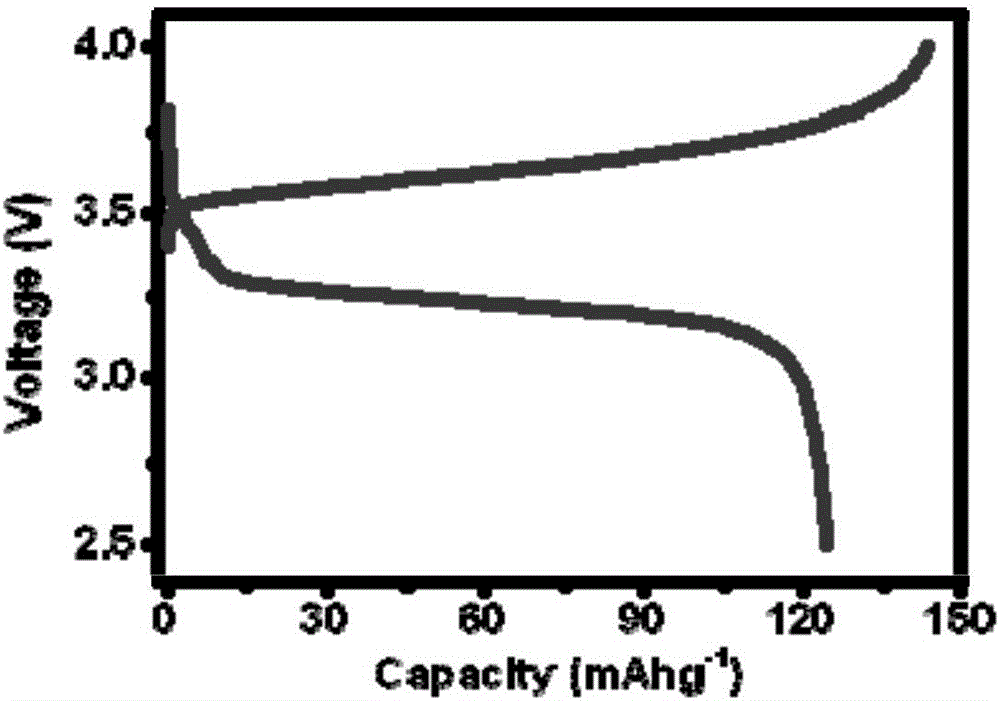

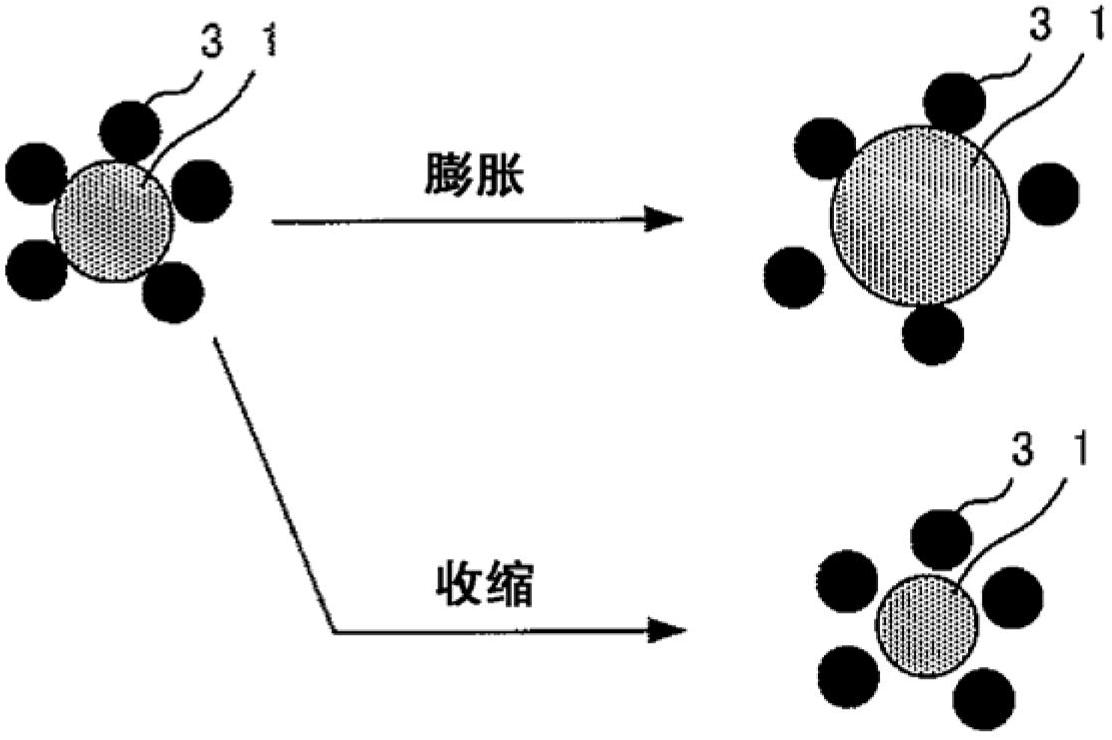

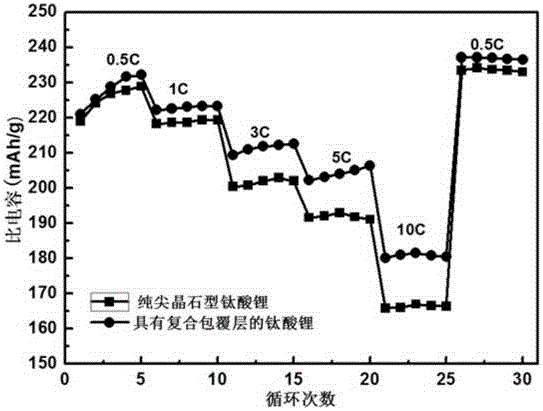

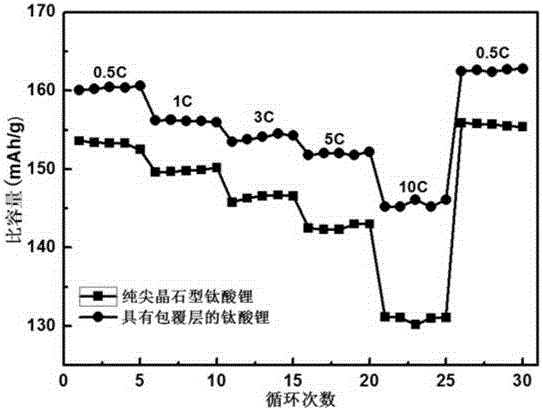

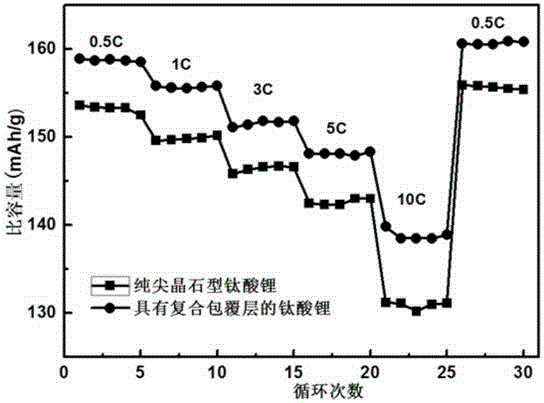

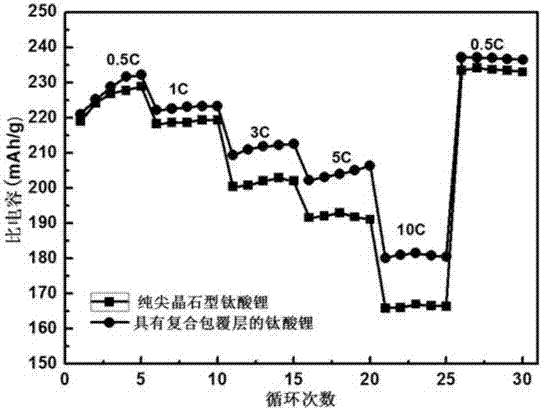

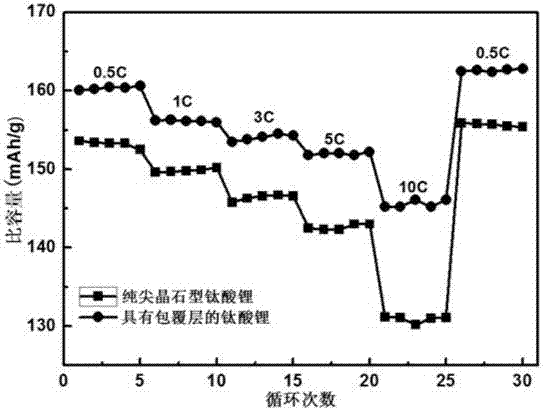

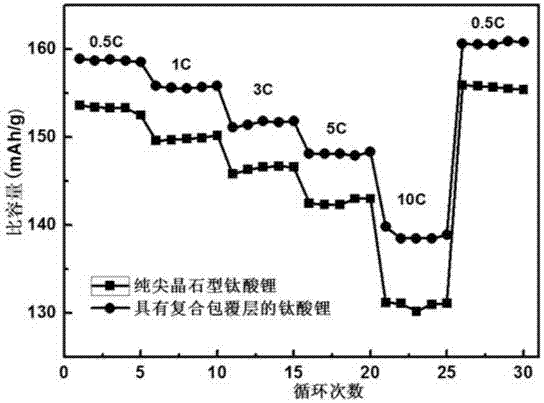

Lithium titanate composite anode material and preparation method thereof

ActiveCN105742618AIncrease capacityImproved magnification performanceCell electrodesSecondary cellsReductive decompositionSolid state electrolyte

The invention discloses a lithium titanate composite anode material and a preparation method thereof. A coating layer coats the outside of the lithium titanate material; and the coating layer is a mixture of LiAlO2 and SiOx. The LiAlO2 on the surface of the anode material has ionic conductivity; the SiOx forms a solid electrolyte in the charge and discharge processes; the LiAlO2 and the SiOx are beneficial to improvement of the capacity and the rate capability of the anode material; the composite LiAlO2 / SiOx coating layer on the surface covers surface-active sites of the lithium titanate material; and reductive decomposition of the electrolyte is inhibited, so that a gas generated when the composite anode material is used as the anode material for a lithium-ion battery is reduced; and the service lifetime is effectively prolonged. The method is an effective path which can improve the capacity and the rate capability of the lithium titanate composite anode material, can prolong the cycle lifetime and can inhibit gas production of the lithium titanate composite anode material; and the method is friendly to environment, simple in process, low in cost and suitable for large-scale production, and has a wide market prospect.

Owner:SHANDONG ZHAOWEN NEW ENERGY TECH CO LTD

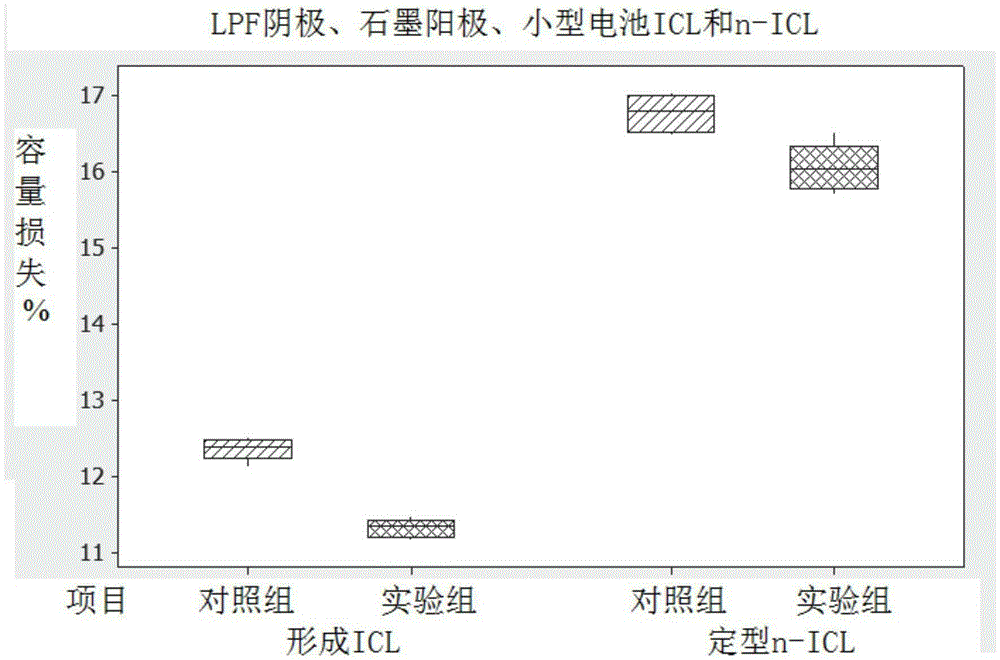

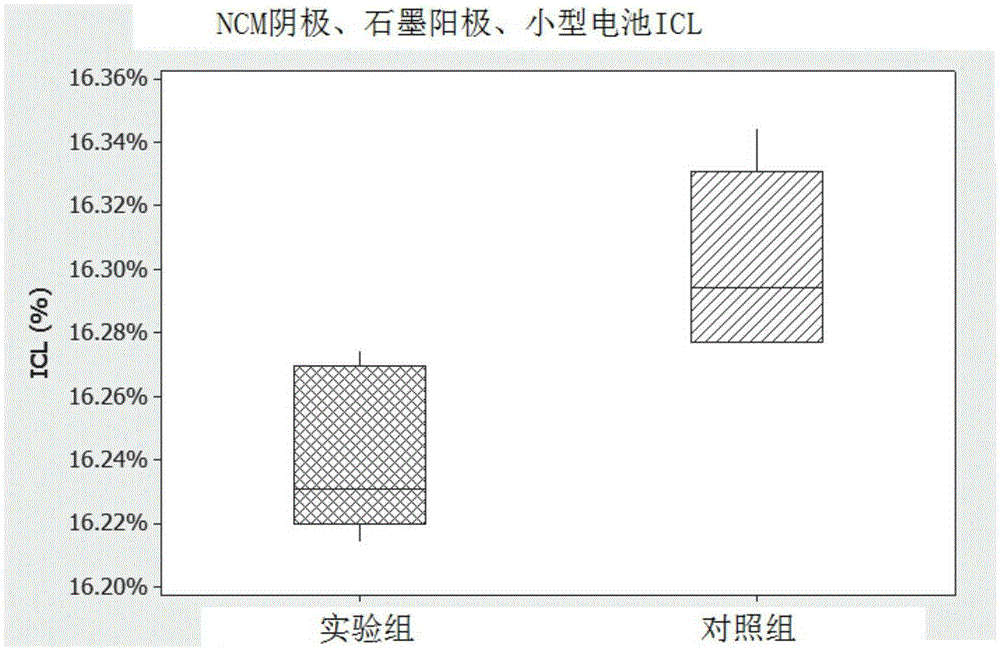

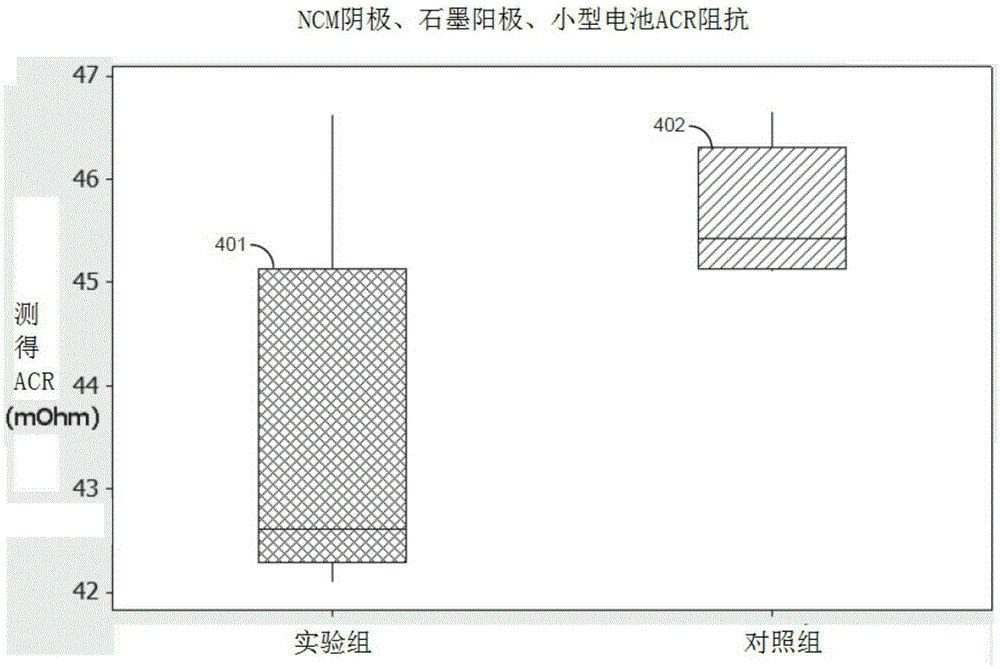

Electrolyte Formulation For Reduced Gassing Wide Temperature Range Cycling

InactiveCN105591150AImprove charge and discharge cycle efficiencyReduce gasCell electrodesFinal product manufactureRechargeable cellAqueous electrolyte

A rechargeable battery cell having a specific combination of anode, cathode and electrolyte formulation is provided. The electrolyte formulation includes an additive system and a salt system. The additive system includes a first additive containing a sulfonyl group, an anti-gassing agent, and a second additive. The salt system includes a lithium salt and a co-salt. The disclosed electrolyte formulation has reduced gassing and improved performance over a wide temperature range.

Owner:A123 SYSTEMS LLC

A functionalized polymer-coated ionic liquid lubricating oil additive and its preparation method and application

ActiveCN110655967BImprove anti-wear performanceImprove extreme pressure performanceAdditivesBulk chemical productionSulfonatePolymer science

The present invention discloses a functional polymer covering liquid liquid lubricant additive, which is a polymer polymer layer on the surface of the ionic liquid on the surface of the ionic liquid, and through the polymer polymer on the polymer polymerThe surface modifier of the layer modifies the carbon -carbon dual -bond sirrius coupling agent is composed of the modified sulfonate layer of the surface of the polymer polymer layer by the cross -linked branches.The functional polymers of the present invention cover the ionic liquid liquid lubricating oil additive in the steel / steel friction vice, which significantly improves the decrease and abrasion resistance of lubricant additives in the friction sideline.Small friction and side loss and long service life.The present invention also disclosed the preparation method and application of functional polymer to cover the ionic liquid lubricant additive.

Owner:圣保路石油化工(天津)股份有限公司

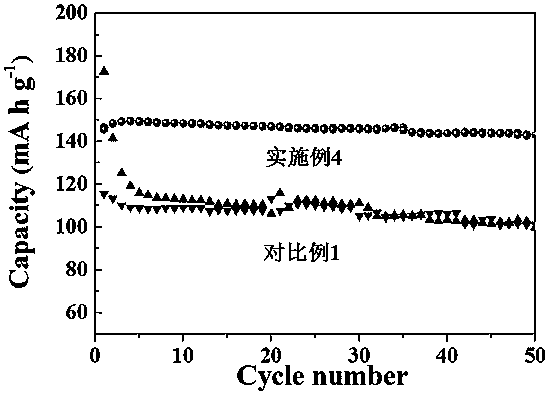

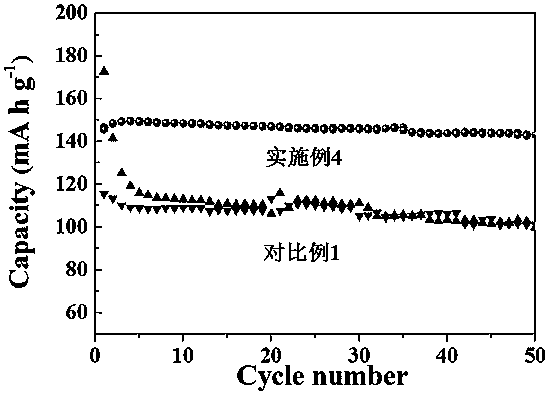

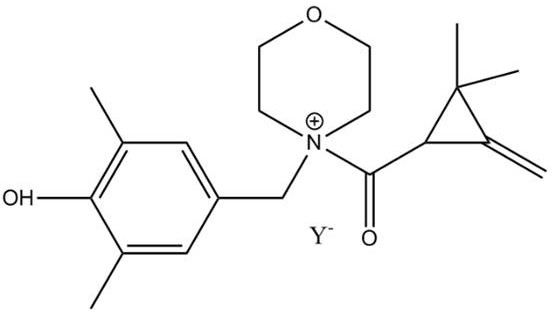

Preparation method and application of a crown ether modified polyaniline solid electrolyte membrane

ActiveCN109411807BImprove ionic conductivityReduce interface contact resistanceSolid electrolytesFinal product manufactureSulfonyl chloridePolymer science

Owner:河南电池研究院有限公司 +1

A kind of multifunctional lubricating oil additive and its application

ActiveCN110423639BImprove anti-wear performanceIntermolecular tightnessOrganic chemistryAdditivesMetallurgyMorpholine

The invention discloses a multifunctional lubricating oil additive. The additive is composed of the following raw materials in parts by weight: 50-100 parts of morpholine ionic liquid; 0.8-7.5 parts of detergent; 1.2-2.6 parts of antirust agent; 7 to 16 parts of agent; and 0.2 to 3.8 parts of foam inhibitor. The multifunctional lubricating oil additive of the present invention is applied in steel / steel or steel / aluminum friction pairs, which significantly improves the friction reduction and anti-wear performance of the lubricating oil additive in the friction pair, and at the same time improves its extreme pressure bearing performance, and the friction pair Small loss and long service life.

Owner:广东顺德菲尔特润滑科技有限公司

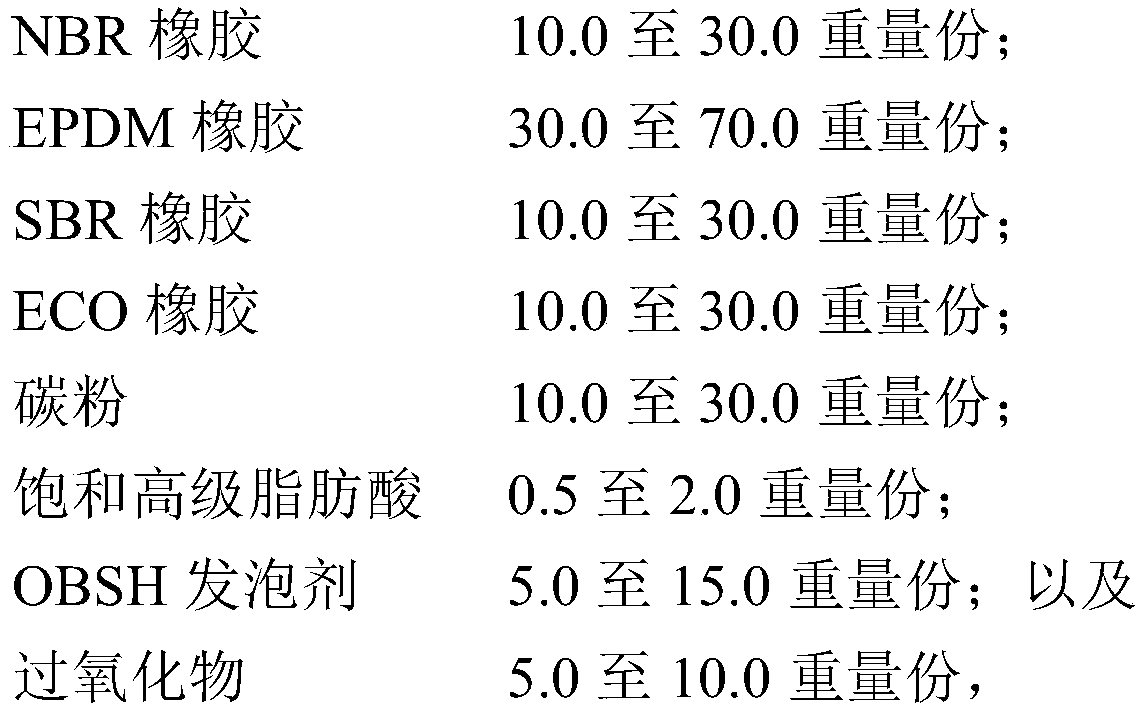

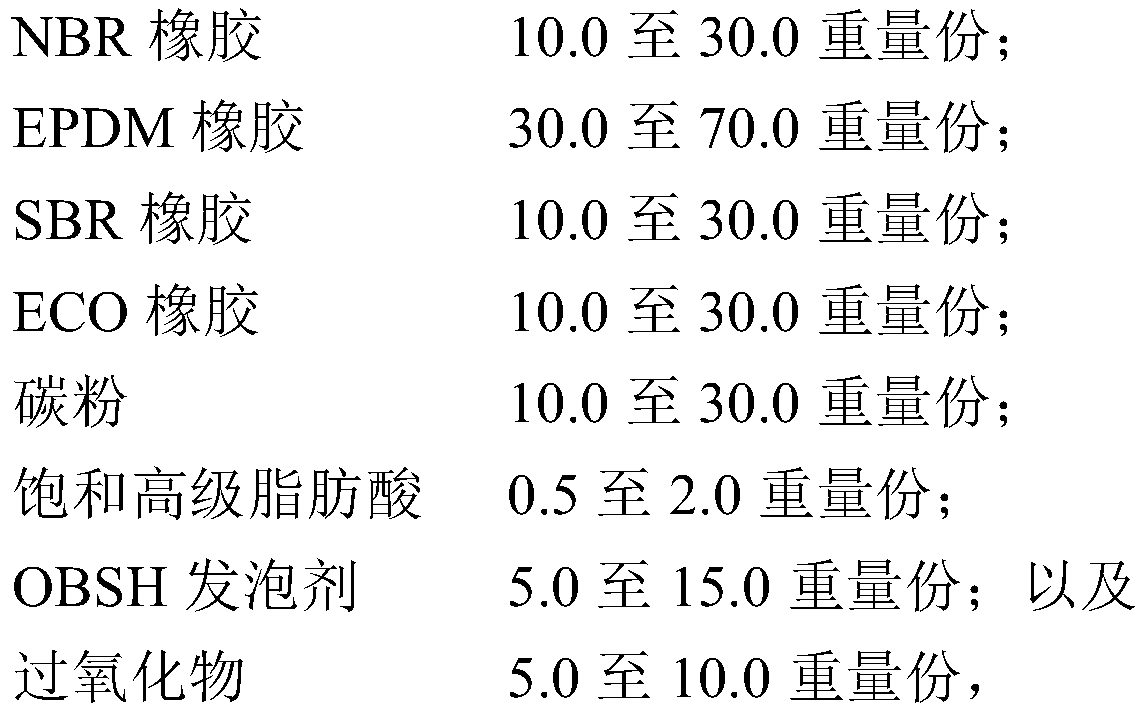

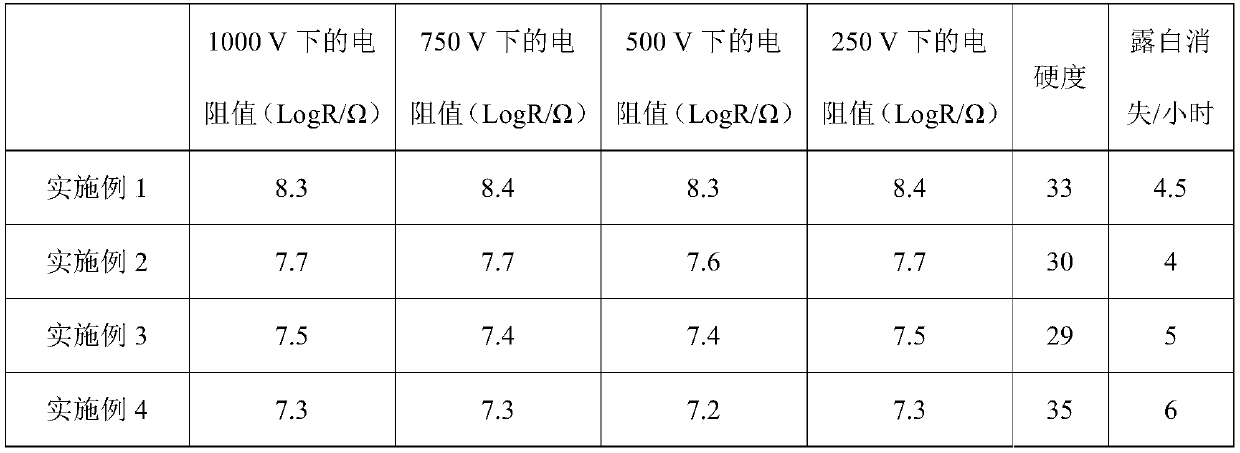

Ionic conductive rubber and preparation method thereof

InactiveCN110591240ANo pollution in the processImprove wear resistanceElectrographic process apparatusPolymer scienceProcess conditions

The invention relates to an ionic conductive rubber and a preparation method thereof. The ionic conductive rubber havs very stable resistivity, is less affected by voltage changes, and maintains goodozone resistance, and high recovery rate and resilience. According to the preparation method, the rubber with ionic conductivity can be obtained by adjusting the component ratio, and complex process conditions are not needed.

Owner:明治橡胶化成(深圳)有限公司

Preparation method of polyacrylonitrile/ionic liquid/polyaniline conductive composite material

The invention discloses a preparation method of a polyacrylonitrile / ionic liquid / polyaniline conducting composite material, which comprises the following steps: (1) adding aniline into 1-butyl-3-methylimidazolyl hexafluorophosphate, and stirring uniformly to obtain a mixed liquid; (2) putting polyacrylonitrile powder into a high-speed mixer, slowly adding the mixed liquid in the step (1), and stirring for 1-3 hours to obtain a mixture; (3) putting the mixture in the step (2) into a mold, and carrying out hot pressing in a flat vulcanizing bed for 10-30 minutes to obtain a polyaniline-monomer-containing polyacrylonitrile sheet; and (4) immersing the sheet in the step (3) into an acid-doped water solution, reacting for 2-10 hours, cleaning the material with water after the reaction finishes, and drying to obtain the polyacrylonitrile / ionic liquid / polyaniline composite conducting material. According to the method, the aniline and ionic liquid plasticizer 1-butyl-3-methylimidazolyl hexafluorophosphate are blended to synergically plasticize the polyacrylonitrile, and then, melting is performed to prepare the product.

Owner:ZHONGYUAN ENGINEERING COLLEGE

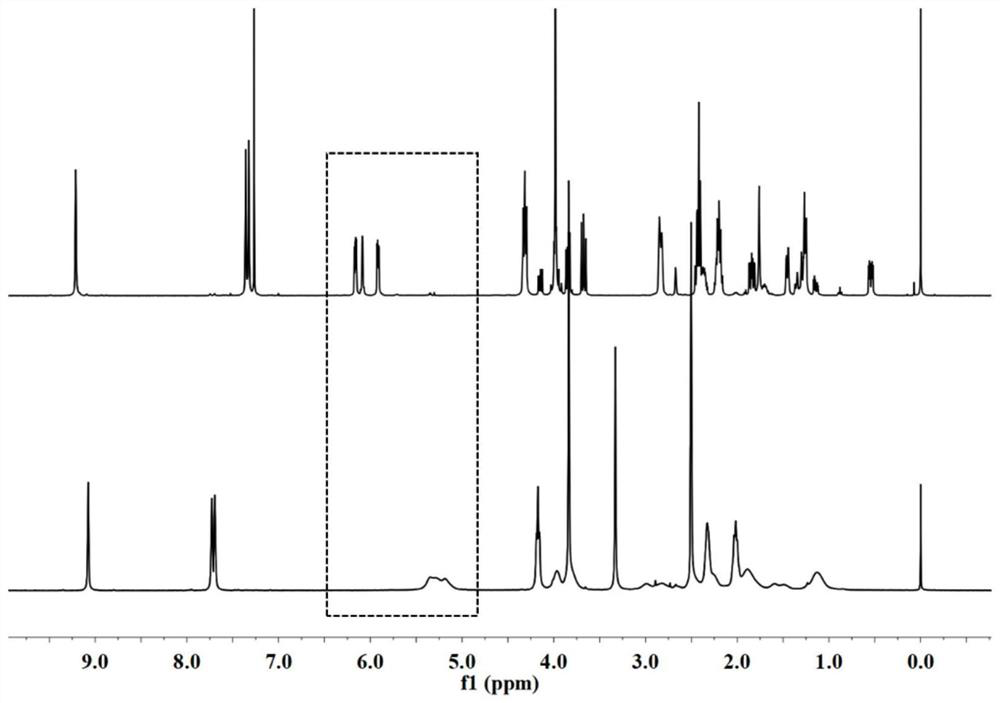

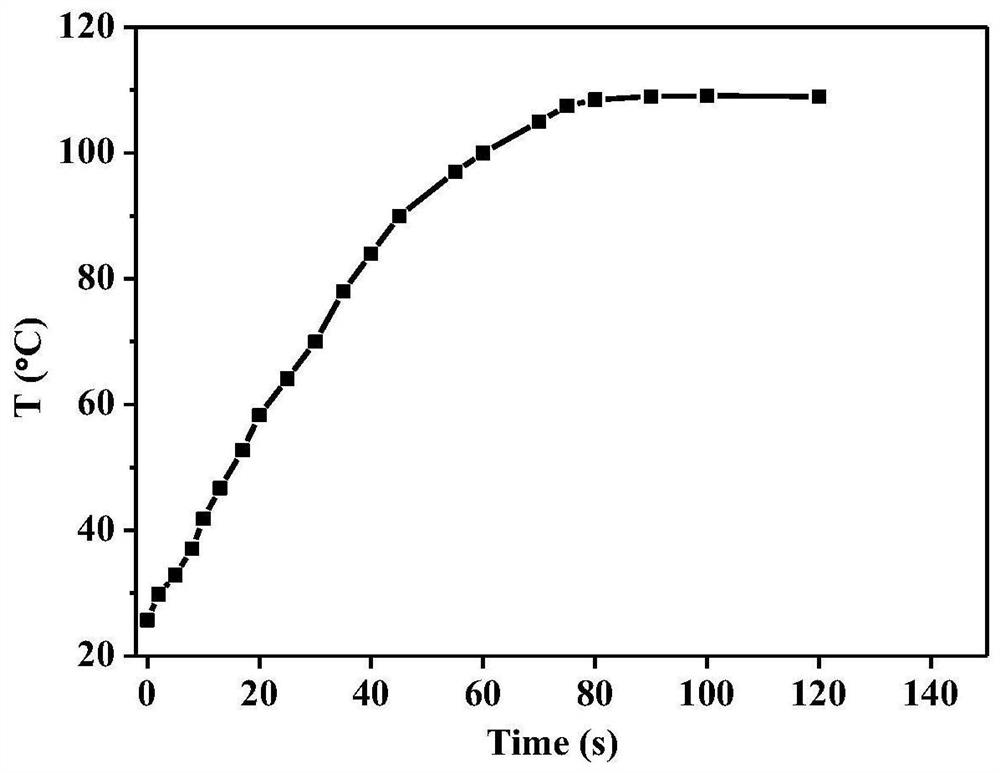

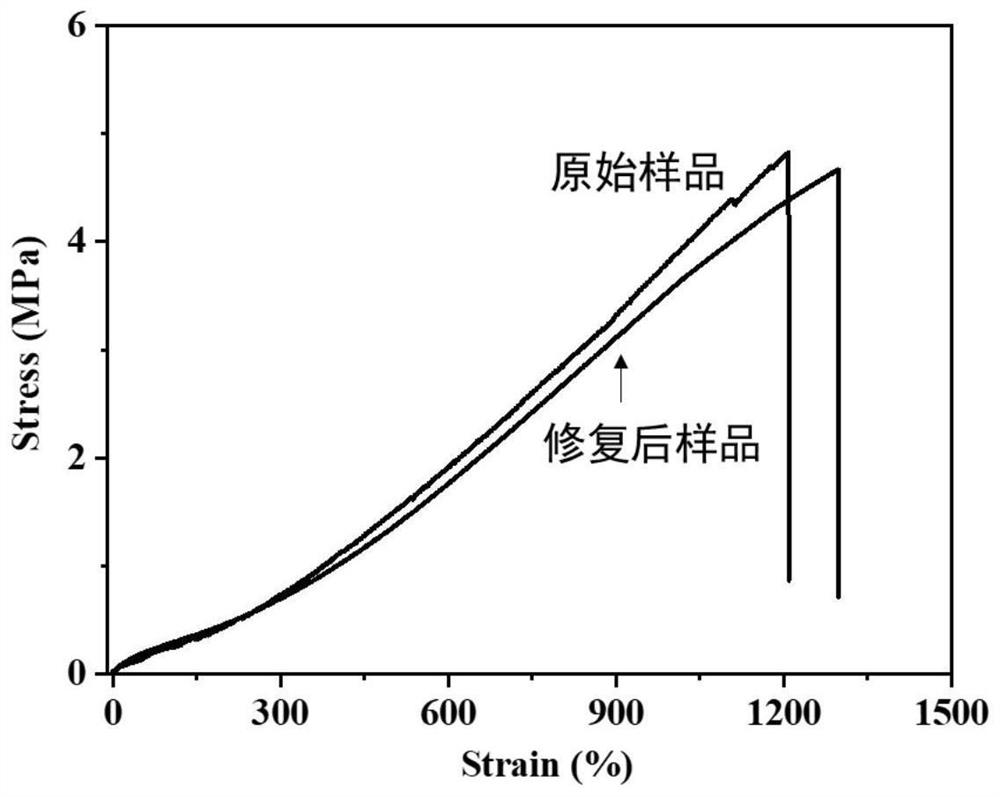

Ionic cycloolefin polymer, photo-self-repairing material based on ionic cycloolefin polymer, and preparation method and application of photo-self-repairing material

ActiveCN113861387AEfficient restorativeAtom utilization is highBulk chemical productionPolymer sciencePtru catalyst

The invention discloses an ionic cycloolefin polymer, a photo-self-repairing material based on the ionic cycloolefin polymer, and a preparation method and application of the photo-self-repairing material, and belongs to the technical field of self-repairing materials. Reversible ions exist in the structure of the prepared ionic cycloolefin polymer, and the polymer shows excellent photothermal conversion capacity under infrared light, so that the polymer has efficient repairing performance under light stimulation; and meanwhile, a Grubbs 3 ruthenium catalyst adopted in the preparation process of the self-repairing material is used for catalyzing ring-opening metathesis polymerization, and after the polymerization reaction is completed and a terminating agent is added, a Grubbs 3 derivative obtained by reacting the Grubbs 3 ruthenium catalyst with the terminating agent also has an excellent photothermal effect, so that a photothermal conversion agent does not need to be additionally added, and the application of the Grubbs 3 ruthenium catalyst is widened.

Owner:TIANJIN UNIV

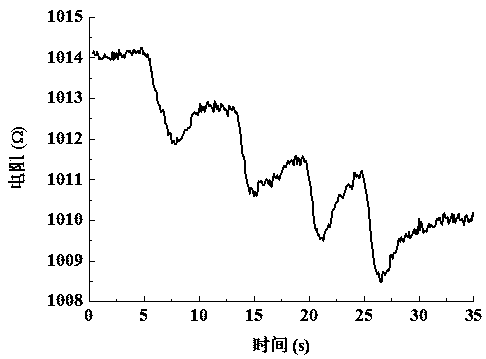

Double-network double-ion conductive transparent electronic skin sensor material and preparation method thereof

InactiveCN109400915AHas ion conductivityEnhanced conductive sensitivityDiagnostic recording/measuringSensorsDouble networkSensor materials

The invention belongs to the technical field of sensor materials, and particularly relates to a double-network double-ion conductive transparent electronic skin sensor material and a preparation method thereof. The preparation method of the double-network double-ion conductive transparent electronic skin sensor material comprises the steps that the surface of nanocellulose is wrapped with anthocyanin and then added into a guar gum glycerin aqueous solution for uniform mixing after being absorbed by iron ions; and after borax solution gelation is carried out, the double-network double-ion conductive electronic skin sensor material is prepared. According to the double-network double-ion conductive transparent electronic skin sensor material and the preparation method thereof, a nanocellulose / anthocyanin composite is utilized to enable guar gum hydrogel to have ultra-sensitive electrical conductivity, so that the guar gum hydrogel can be used as a novel electronic skin sensor material.

Owner:FUJIAN AGRI & FORESTRY UNIV

A kind of lithium titanate composite negative electrode material and preparation method thereof

ActiveCN105742618BHas ion conductivityInhibition of reductive decompositionCell electrodesSecondary cellsReductive decompositionSolid state electrolyte

The invention discloses a lithium titanate composite anode material and a preparation method thereof. A coating layer coats the outside of the lithium titanate material; and the coating layer is a mixture of LiAlO2 and SiOx. The LiAlO2 on the surface of the anode material has ionic conductivity; the SiOx forms a solid electrolyte in the charge and discharge processes; the LiAlO2 and the SiOx are beneficial to improvement of the capacity and the rate capability of the anode material; the composite LiAlO2 / SiOx coating layer on the surface covers surface-active sites of the lithium titanate material; and reductive decomposition of the electrolyte is inhibited, so that a gas generated when the composite anode material is used as the anode material for a lithium-ion battery is reduced; and the service lifetime is effectively prolonged. The method is an effective path which can improve the capacity and the rate capability of the lithium titanate composite anode material, can prolong the cycle lifetime and can inhibit gas production of the lithium titanate composite anode material; and the method is friendly to environment, simple in process, low in cost and suitable for large-scale production, and has a wide market prospect.

Owner:SHANDONG ZHAOWEN NEW ENERGY TECH CO LTD

Composite binder for solid-state lithium battery and preparation method thereof

ActiveCN109860595BHas ion conductivityImprove adhesionNon-macromolecular adhesive additivesCell electrodesOrganic solventInternal resistance

The invention discloses a composite binder for solid-state lithium batteries and a preparation method thereof. The composite binder is composed of a high molecular polymer, a lithium salt and an inorganic ceramic fast ion conductor. The preparation method is to dissolve the high molecular polymer with an organic solvent. compound, lithium salt and inorganic ceramic fast ion conductor, under certain temperature and stirring conditions, an organic-inorganic composite binder complexed with lithium salt and inorganic fast ion conductor is formed. The binder has strong cohesive force and adhesion, as well as high ionic conductivity, and is used for the preparation of positive and negative pole pieces of solid-state lithium batteries, which can reduce the internal resistance of the pole pieces and improve the rate performance of solid-state lithium batteries. and cycle life.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

All-solid-state acetylcholine sensor and preparation method thereof

ActiveCN105092668BElectronically conductiveHas ion conductivityMaterial electrochemical variablesSolid state electrolyteExternal reference

The invention discloses an all-solid-state acetylcholine sensor, which includes an external reference electrode and a selective electrode. The selective electrode includes a metal wire, a solid electrolyte layer and an acetylcholine sensitive film. One end of the metal wire is sequentially coated There is a detection end of a solid electrolyte layer and an acetylcholine sensitive film, and the acetylcholine sensitive film is coated on a part of the surface of the solid electrolyte layer; the other end of the metal wire is a bare electrical signal output end; the acetylcholine The sensitive membrane contains 2-nitrophenyl octyl ether. The all-solid-state acetylcholine sensor integrates an acetylcholine selective electrode and an external reference electrode, which is convenient for storage and use, and has the advantages of simple operation, rapid response, stable operation and long service life.

Owner:ZHEJIANG UNIV

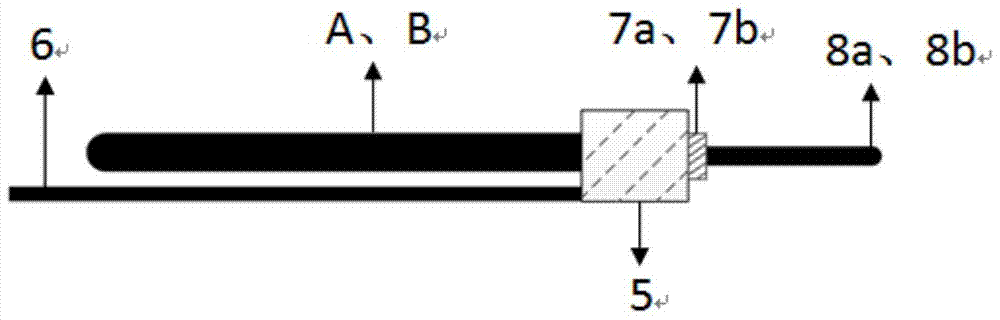

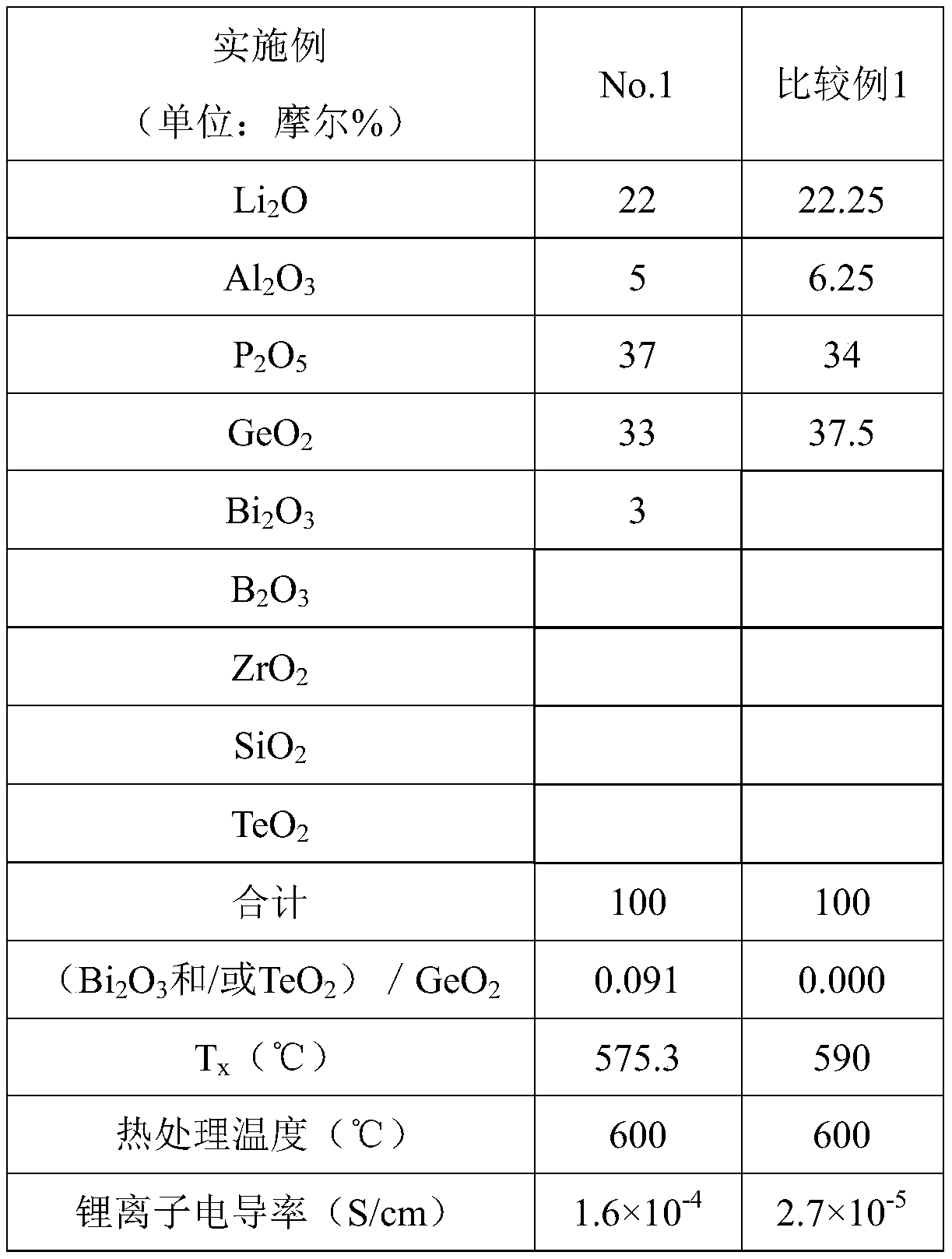

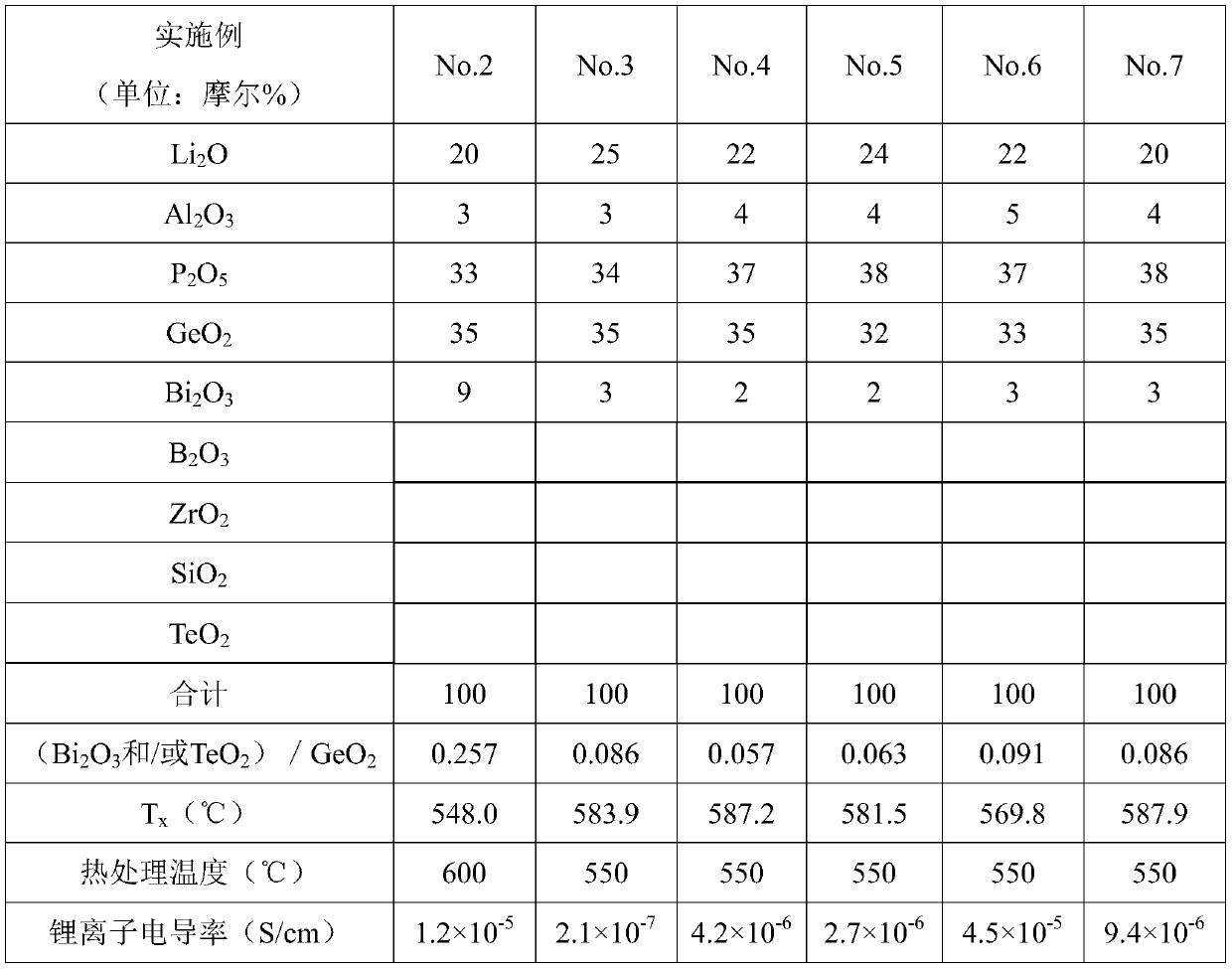

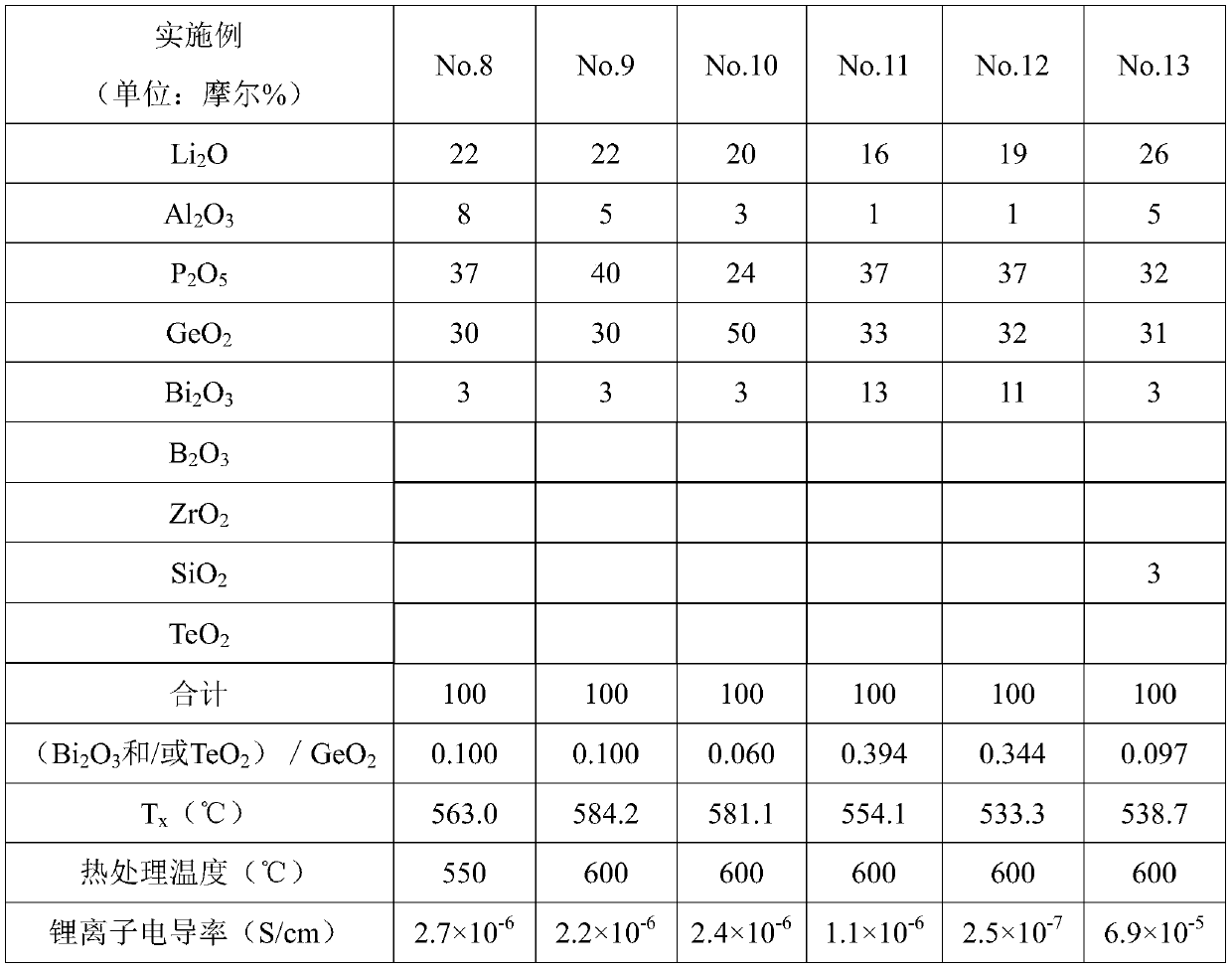

Lithium ion conductor precursor glass and lithium ion conductor

ActiveCN111247106AHas ion conductivitySolid electrolytesOxide conductorsChemical physicsElectrical conductor

As a solid electrolyte used in a lithium ion secondary battery, it has not been possible to obtain a lithium ion conductor precursor glass and a lithium ion conductor in which crystallization progresses at low temperatures and which exhibit high ion conductivity. The present invention can obtain a lithium ion conductor precursor glass and a lithium ion conductor in which crystallization progresseseven at low temperatures and which exhibit high ion conductivity by containing 10-35% of a Li2O component, 20-50% of a P2O5 component, greater than 0% to 15% of an Al2O3 component, 20-50% of a GeO2 component and greater than 0% to 15% of a Bi2O3 component and / or a TeO2 component.

Owner:OHARA +1

Materials suitable for anodic bonding and methods for their preparation

The embodiments of the invention provide a material applicable to anode bonding and a preparation method thereof and relate to the field of material preparation. Due to the application of the material, the preheating temperature during anode bonding encapsulation can be lowered, the residual stress of sealing can be reduced, and the quality of microelectronic device encapsulation is improved. The preparation method comprises the steps: uniformly mixing one of LiBF4, LiPF6, TiO2 and Al2O3 and an equal amount of LiClO4, and sintering by adopting a solid-phase reaction method, so as to obtain a complex; and baking the complex and polyethylene oxide (PEO) powder, and then, putting into an agate ball tank for ball milling, thereby preparing the macromolecular solid electrolyte material applicable to anode bonding.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

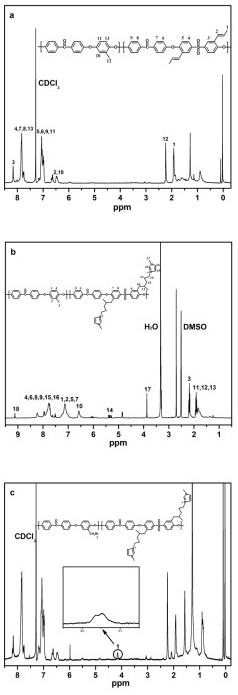

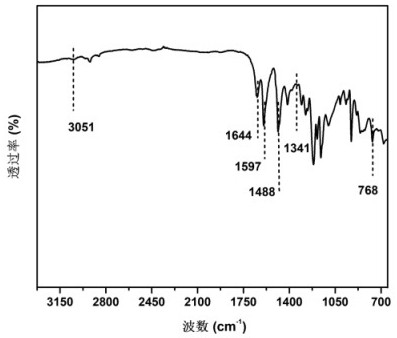

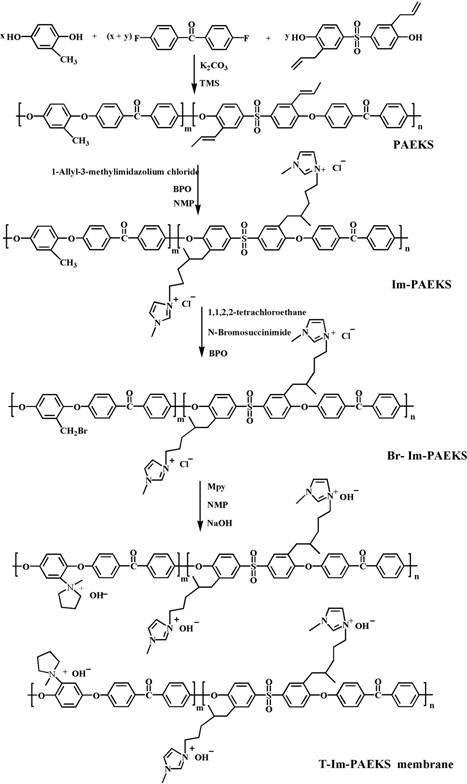

Different-side-chain type anion exchange membranes for fuel cell and preparation method of membranes

PendingCN112300391ASolve the problem of decreased ionic conductivityImprove compactnessFuel cellsFuel cellsSide chain

The invention provides a different-side-chain type anion exchange membranes for a fuel cell and a preparation method of the anion exchange membranes, and belongs to the field of polymer chemistry andanion exchange membrane fuel cells. According to different molar ratios of monomers, the molar ratio of a methyl hydroquinone monomer to an allyl bisphenol S monomer is a:b (a and b are both integersof 1-9 and a+b is equal to 10); the invention also provides a preparation method of the different-side-chain type anion exchange membranes, which comprises the following steps: conducting polymerizingaccording to different molar ratios of monomers by utilizing nucleophilic polycondensation reaction to form polyaryletherketone containing different proportions of the methyl hydroquinone monomer tothe allyl bisphenol S-containing monomer, thereby preparing the different-side-chain type anion exchange membranes. The highest ionic conductivity of the different-side-chain type anion exchange membranes at 80 DEG C can reach 0.137 S / cm.

Owner:CHANGCHUN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com