Ionic cycloolefin polymer, photo-self-repairing material based on ionic cycloolefin polymer, and preparation method and application of photo-self-repairing material

A cyclic olefin polymer and self-healing material technology, applied in the field of self-healing materials, can solve the problems of complex preparation process and promotion limitations, and achieve the effects of good substrate universality, obvious photothermal effect, and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

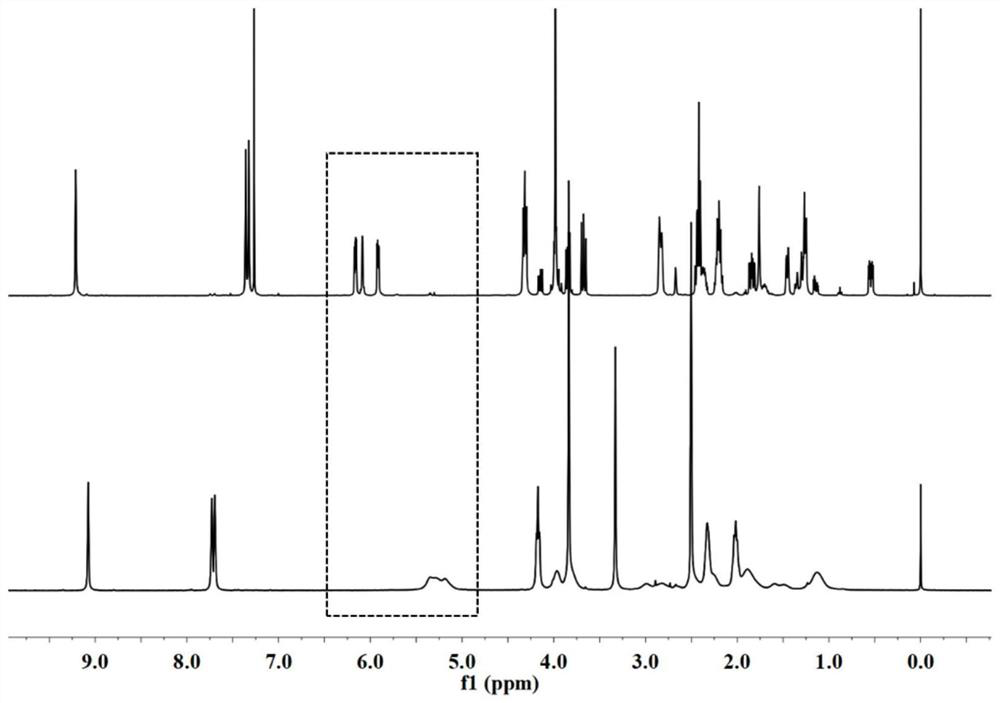

[0049] The general structural formula of ionic cycloolefin polymer is:

[0050]

[0051] Wherein, side chain length m=3, n=0, degree of polymerization y=100, X=perfluorobutanesulfonic acid anion (CF 3 (CF 2 ) 3 SO 3 - ), the synthesis steps are as follows:

[0052] The following operations were all carried out in a Braun (Mbraun) glove box: 3-(2-(bicyclo[2.2.1]hept-5-en-2-ylmethoxy)-2-oxo was added to a 50mL polymerization bottle Substituted alkyl)-1-methyl-1hydrogen-imidazole perfluorobutanesulfonate (1.0g, 1.74mmol) and 10mL ultra-dry dichloromethane were stirred and mixed for 15 minutes. Add 15.4mg (0.0174mmol) of dichloro[1,3-bis(2,4,6-trimethylphenyl)-2-imidazolidinylidene](benzylidene)bis(3- bromopyridine) ruthenium (II) catalyst and 2 mL of dichloromethane to obtain a catalyst solution. Under the condition of stirring, the catalyst solution was added into the above-mentioned polymerization bottle to carry out the polymerization reaction at 25° C. for 12 hours,...

Embodiment 2

[0062] The general structural formula of ionic cycloolefin polymer is:

[0063]

[0064] Wherein side chain length m=3, n=0, degree of polymerization y=800, X=perfluorobutanesulfonic acid anion (CF 3 (CF 2 ) 3 SO 3 - ), the synthesis steps are as follows:

[0065] The following operations were all carried out in a Braun (Mbraun) glove box: 3-(2-(bicyclo[2.2.1]hept-5-en-2-ylmethoxy)-2-oxo was added to a 50mL polymerization bottle Substituted alkyl)-1-methyl-1hydrogen-imidazole perfluorobutanesulfonate (1.0g, 1.74mmol) and 10mL ultra-dry dichloromethane were stirred and mixed for 15 minutes. Add 1.93mg (0.0022mmol) of dichloro[1,3-bis(2,4,6-trimethylphenyl)-2-imidazolidinylidene](benzylidene)bis(3- bromopyridine) ruthenium (II) catalyst and 0.5 mL of dichloromethane to obtain a catalyst solution. Under the condition of stirring, the catalyst solution was added into the above-mentioned polymerization bottle to carry out the polymerization reaction at 40° C. for 12 hours...

Embodiment 3

[0070] The general structural formula of ionic cycloolefin polymer is:

[0071]

[0072] Wherein side chain length m=3, n=4, degree of polymerization y=100, X=two trifluoromethylsulfonimide anion (Tf 2 N - ), the synthesis steps are as follows:

[0073] The following operations were all carried out in a Braun (Mbraun) glove box: 3-(2-(bicyclo[2.2.1]hept-5-en-2-ylmethoxy)-2-oxo was added to a 50mL polymerization bottle Substituted alkyl)-1-methyl-1hydrogen-imidazole perfluorobutanesulfonate (1.0g, 1.64mmol) and 10mL ultra-dry dichloromethane were stirred and mixed for 15 minutes. Add 14.48mg (0.0164mmol) of dichloro[1,3-bis(2,4,6-trimethylphenyl)-2-imidazolidinylidene](benzylidene)bis(3- bromopyridine) ruthenium (II) catalyst and 2 mL of dichloromethane to obtain a catalyst solution. Under the condition of stirring, the catalyst solution was added into the above-mentioned polymerization bottle to carry out the polymerization reaction at 30° C. for 12 hours, and the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

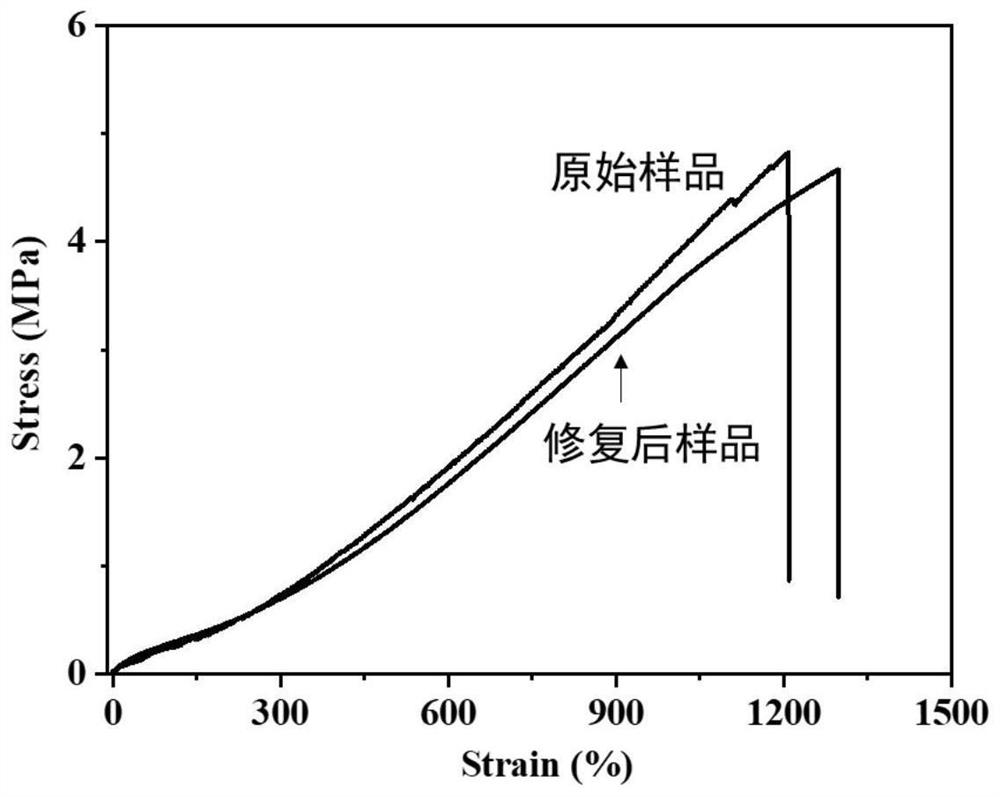

| thickness | aaaaa | aaaaa |

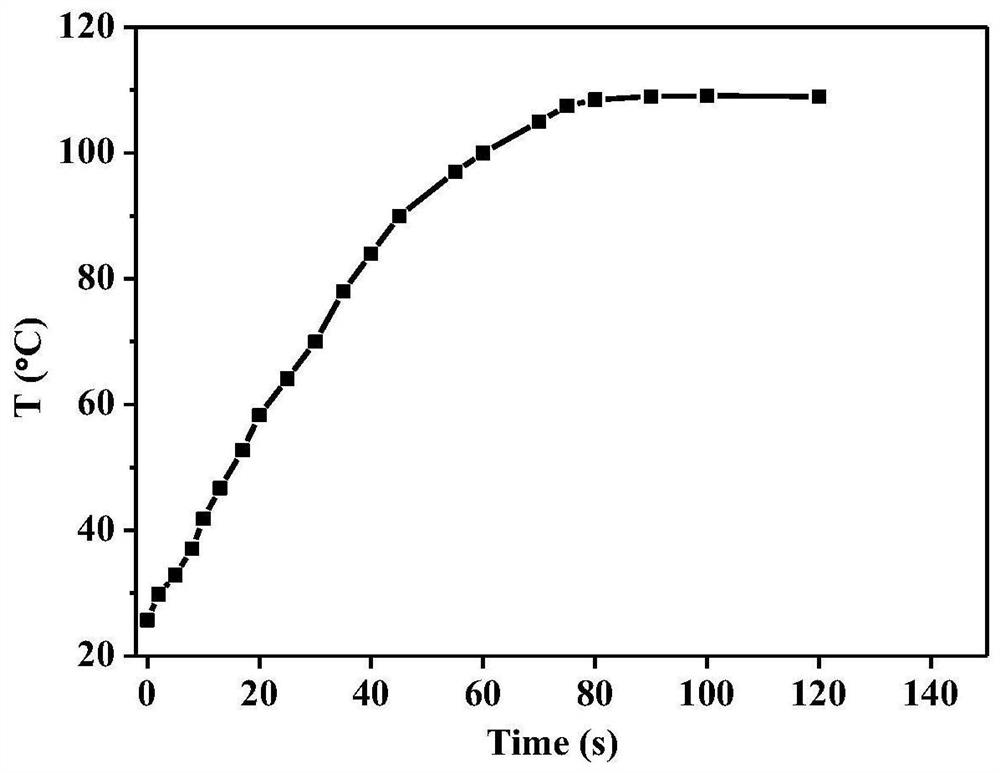

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com