Polymer damping material capable of being repaired at room temperature and preparation method and application thereof

A technology of damping materials and polymers, which is applied in the field of polymer damping materials and their preparation, can solve the problems of limited material application and impracticability, and achieve the effects of good transparency, efficient repair performance, and excellent remodeling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

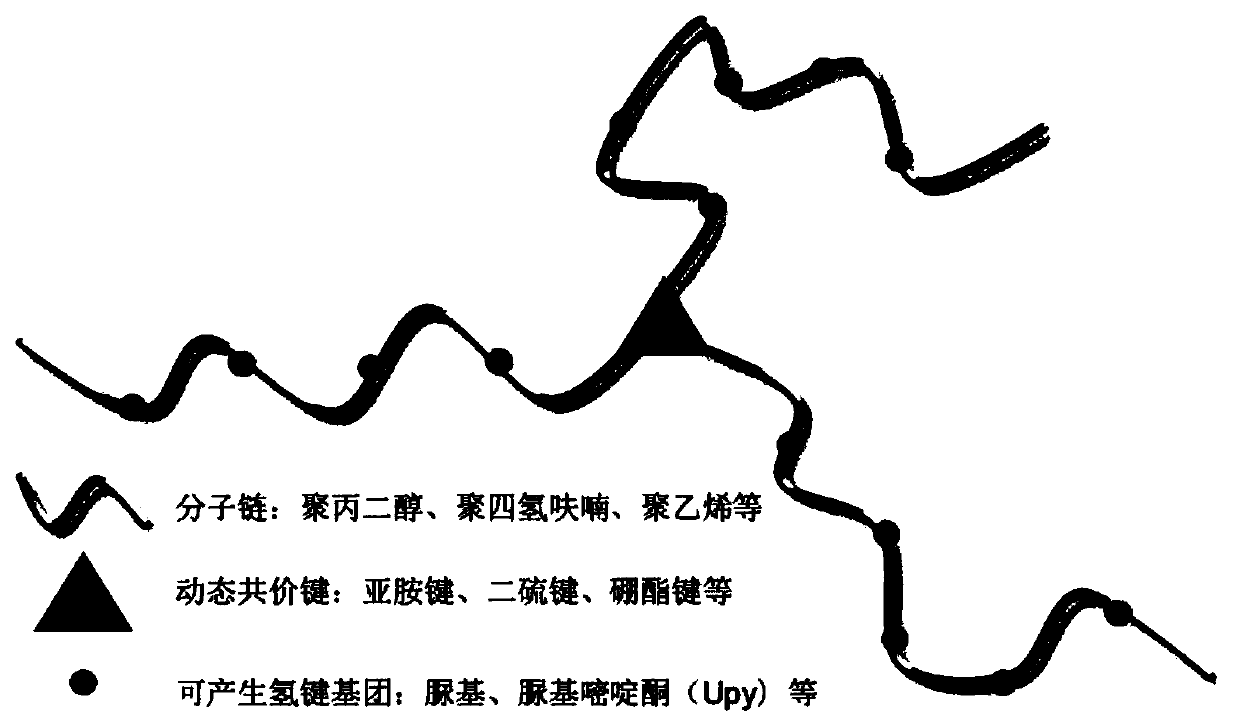

[0049] The present invention provides a method for preparing a polymer damping material that can be repaired at room temperature described in the above technical solution, comprising the following steps:

[0050] Mix polyol, isocyanate and solvent for polycondensation reaction to obtain polyurethane;

[0051] The polyurethane, the chain-extending cross-linking agent and the solvent are mixed to carry out a cross-linking reaction to obtain a polymer damping material that can be repaired at room temperature.

[0052] The invention mixes polypolyol, isocyanate and solvent to carry out polycondensation reaction to obtain polyurethane.

[0053] In the present invention, the order of mixing the polypolyol, isocyanate and solvent is preferably to mix the polypolyol and the solvent for the first time to obtain a polypolyol solution; to mix the isocyanate and the solvent for the second time to obtain an isocyanate solution; Under bath conditions, the isocyanate solution is added dropw...

Embodiment 1

[0070] Preparation of polymer damping materials that can be repaired at room temperature, the preparation route is as follows:

[0071]

[0072] Wherein, the short wavy line in formula I represents the molecular chain of polypropylene glycol, and the long wavy line in formula II represents the molecular chain of the knot structure in formula I.

[0073] Amino-terminated polypropylene glycol (4 g) with a molecular weight of 400 was dissolved in 30 mL of ultra-dry N,N'-dimethylacetamide (DMAc), stirred at room temperature (25°C) for 10 min, and then cooled in an ice bath. Stir until the system temperature is <5°C to obtain a polypropylene glycol solution; dissolve isophorone diisocyanate (IPDI, 6mmol) in DMAc (10mL) to obtain an isocyanate solution; add the isocyanate solution dropwise at a constant speed of 2 drops / second Into the polypropylene glycol solution, react at room temperature for 24h to obtain polyurethane;

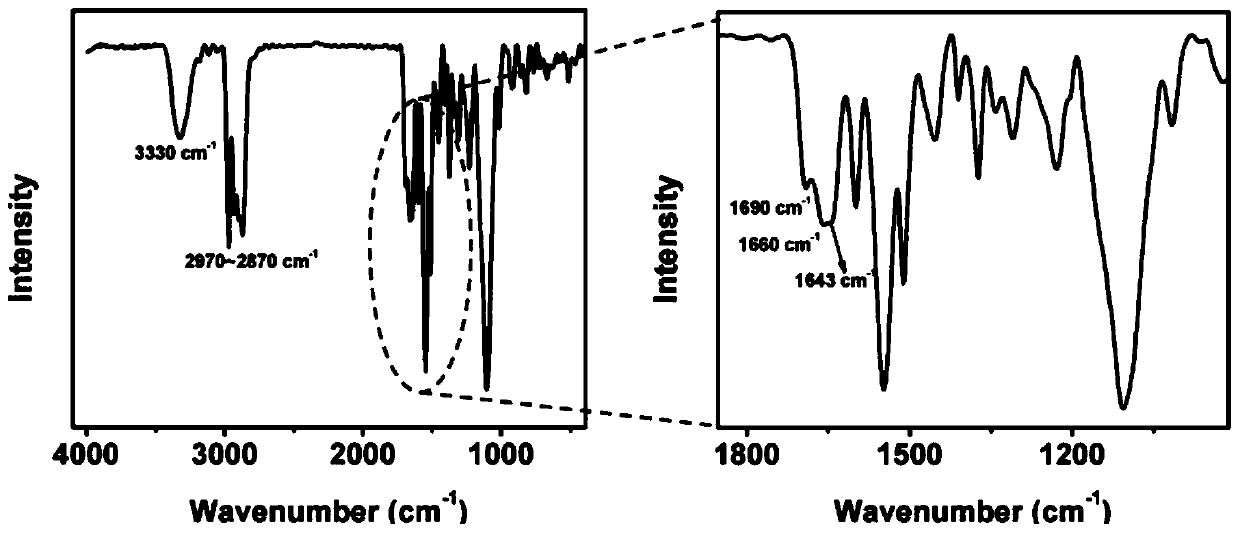

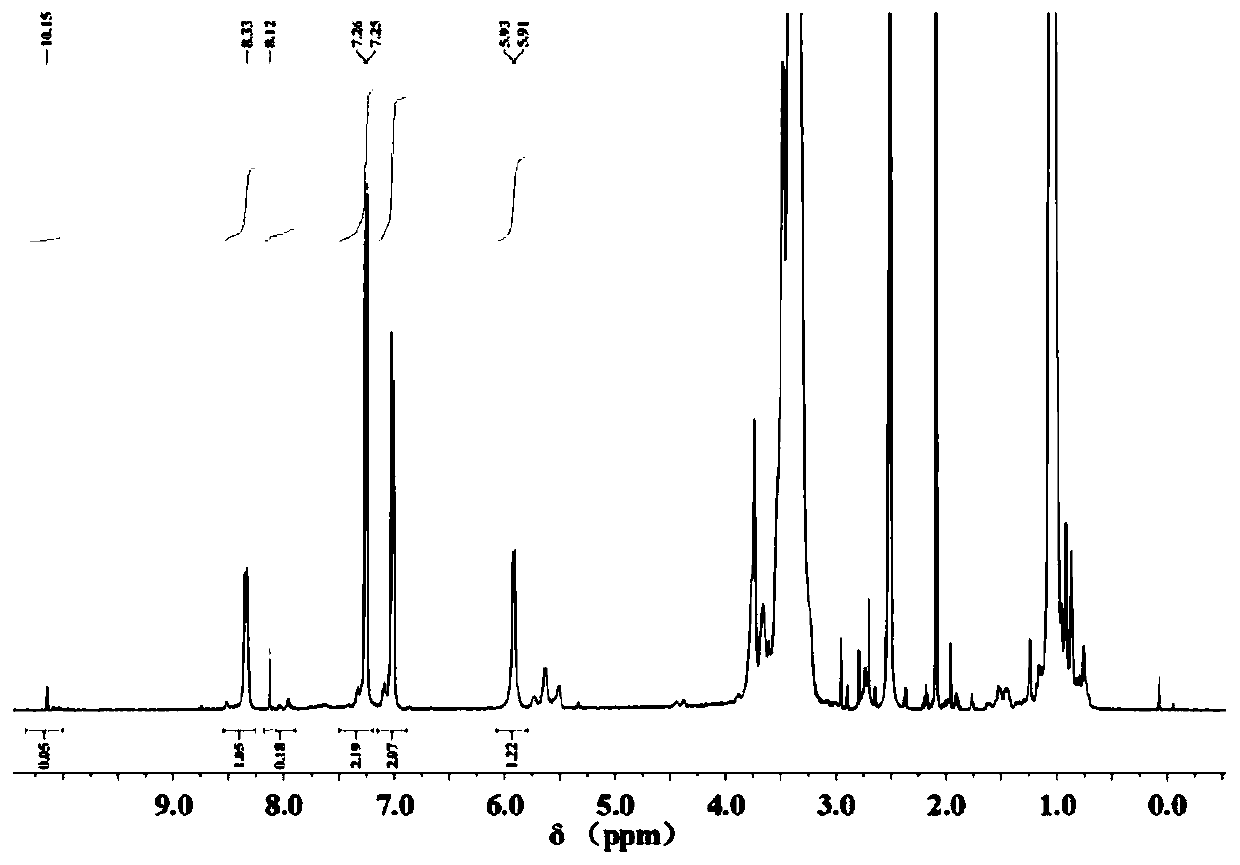

[0074] Dissolve trimesaldehyde (8mmol) in DMAc (10mL) ...

Embodiment 2

[0084]Dissolve hydroxyl-terminated polypropylene glycol with a molecular weight of 1000 (2 g) and hydroxyl-terminated polypropylene glycol with a molecular weight of 800 (8 g) in 80 mL of ultra-dry N,N'-dimethylacetamide (DMAc) at room temperature (25 °C ) under the condition of stirring for 10min, and then stirring under the condition of ice bath until the system temperature was <5°C to obtain a polypropylene glycol solution; dissolving isophorone diisocyanate (IPDI, 3mmol) and diphenylmethane diisocyanate (MDI, 7mmol) In DMAc (10mL), an isocyanate solution was obtained; the isocyanate solution was added dropwise to the polypropylene glycol solution at a constant rate of 2 drops / second, and 3 drops of dibutyltin dilaurate were added dropwise to the resulting reaction system. Reaction 24h, obtains polyurethane;

[0085] Dissolve trimesaldehyde (8mmol) in DMAc (10mL) solution, add the obtained trimesaldehyde solution dropwise to the polyurethane system, react at 80°C for 24h, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com