Lithium battery composite diaphragm as well as preparation method and application thereof

A composite diaphragm and lithium battery technology, which is applied to lithium batteries, secondary batteries, battery pack components, etc., can solve the problems of battery material damage and difficulty in ensuring battery safety, and achieve improved stability, good stability, and halogen The effect of low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] A preparation method of lithium battery composite diaphragm,

[0124] (1) Add 0.5 parts by weight of dispersant sodium polyacrylate to solvent water, stir thoroughly, then add 100 parts by weight of oxide solid electrolyte particles LiHAl(PO 4 )O 0.95 f 0.1 , the particle size is 600nm, the ball mill is uniform, and slurry A is prepared, and then continue to add 1 weight part of thickener sodium carboxymethyl cellulose, 5 weight parts of binder polyacrylate and 0.4 weight part of wetting agent sodium perfluorooctanoate, Solid electrolyte accounted for 94wt%, fully stirred to prepare slurry B;

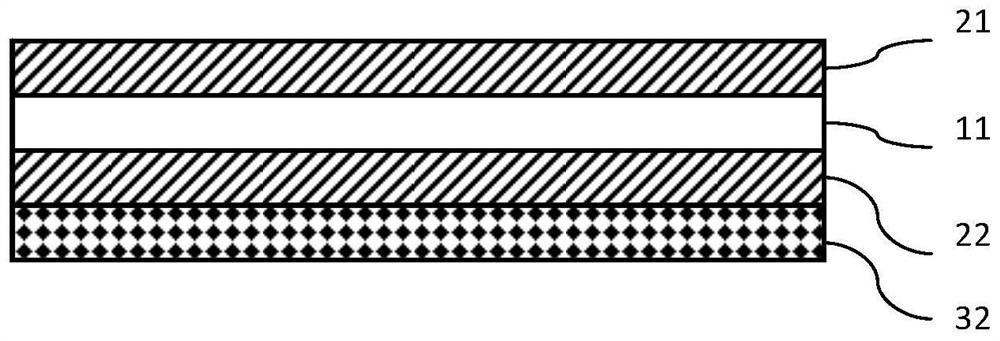

[0125] (2) Slurry B is scraped and coated on a polyethylene-based film with aluminum oxide coating on both sides by a micro-gravure coating machine, baked at 40°C for 2 minutes to form an oxide solid electrolyte coating, and wound to obtain the composite Diaphragm, the structure is shown as figure 1 shown.

[0126] The lithium battery composite diaphragm prepared by the abov...

Embodiment 2

[0135] The solid electrolyte particles were replaced by LiHAl(PO 4 )O 0.96 f 0.08 , the battery structure is LCO||graphite, and other parameters are the same as in Example 1; the specific electrochemical performance test results of the prepared lithium battery are shown in Table 1, and the safety performance test results are shown in Table 2.

[0136] Lithium-containing material LiHAl(PO 4 )O 0.96 f 0.08 The preparation method is as follows:

[0137] Step (1) Stir and mix evenly according to lithium salt lithium carbonate, aluminum-containing material alumina, phosphorus-containing material phosphorus pentoxide and halogen-containing material hydrogen fluoride, wherein the molar ratio of Li, Al, P, and halogen is 12.5:12.5:12.5: 1. The mixing time is 30min, and the stirring rate is 200rpm; the mixture is obtained;

[0138] Step (2) sintering the mixture, the temperature of the sintering treatment is 300°C, and the sintering time is 200h; the sintering atmosphere is a nit...

Embodiment 3

[0141] The solid electrolyte particles were replaced by LiHAl(PO 4 )O 0.94 Cl 0.12 , the battery structure is NCM||graphite, and other parameters are the same as in Example 1; the specific electrochemical performance test results of the prepared lithium battery are shown in Table 1, and the safety performance test results are shown in Table 2.

[0142] Lithium-containing material LiHAl(PO 4 )O 0.94 Cl 0.12 The preparation comprises the following steps:

[0143] Step (1) Stir and mix evenly according to the lithium salt lithium acetate, the aluminum-containing material aluminum hydroxide, the phosphorus-containing material phosphine, and the halogen-containing material phosphorus chloride, wherein the molar ratio of Li, Al, P, and halogen is 16.6:16.6: 16.6:1, the mixing time is 1min, and the stirring rate is 1800rpm; the mixture is obtained;

[0144] Step (2) Sintering the mixture, the temperature of the sintering treatment is 500°C, and the sintering time is 100h; the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com