Ionic conductive rubber and preparation method thereof

A technology of ion conduction and rubber, which is applied in the field of polymers, can solve problems such as resistivity fluctuations, electronically conductive rubber voltage changes, and increase the difficulty of rubber preparation, so as to achieve improved heat resistance, improved resilience, and improved recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

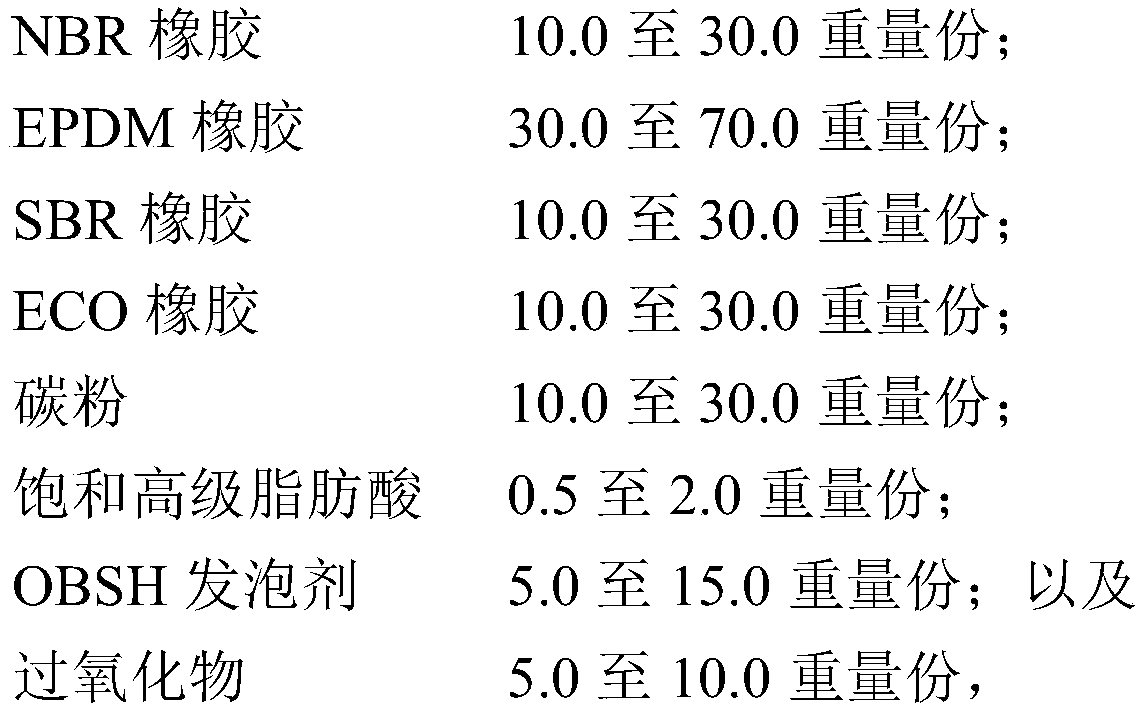

Method used

Image

Examples

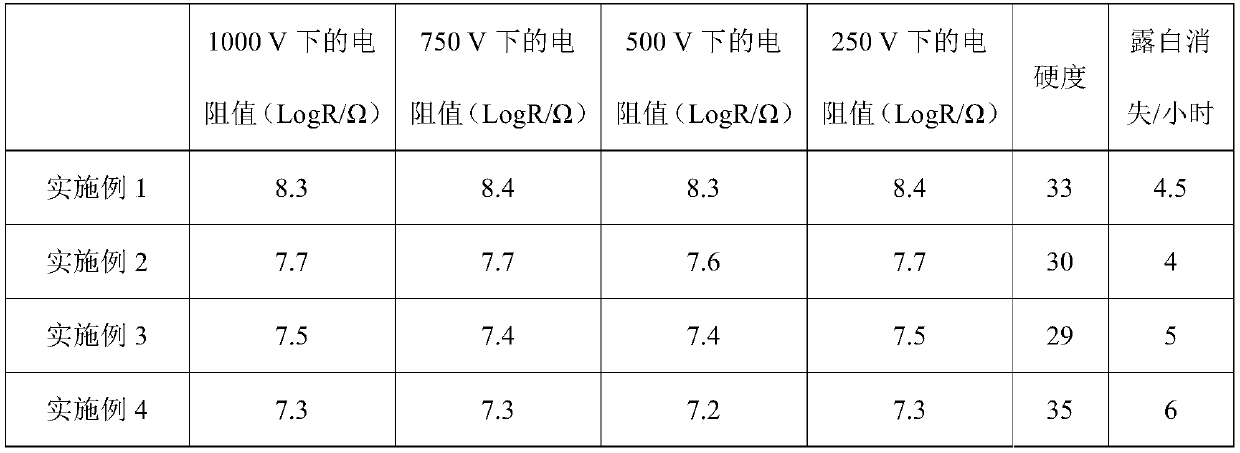

Embodiment 1

[0067] (1) The first kneading: put 1.0kg of NBR rubber, 7.0kg of EPDM rubber, 1.0kg of SBR rubber, 1.0kg of ECO rubber, 2.0kg of carbon black and 0.12kg of DTST into the internal mixer Refining for 12 minutes while controlling the system temperature below 100°C. Afterwards, the resultant was left to cool for more than 24 hours to stabilize the chemical properties.

[0068] (2) The second kneading: the dicumyl peroxide of the first kneading gain, 1.1kg blowing agent OBSH and 0.7kg was kneaded in an open mill for 30 minutes, while controlling the temperature of the system at 90 ℃ below to fully mix the three materials. Afterwards, the resultant was left to cool for more than 24 hours to stabilize the chemical properties. Afterwards, the second kneaded product is extruded into a hollow rubber rod by an extruder, and the temperature is controlled below 70°C during extrusion, and then left for more than 12 hours.

[0069] (3) Vulcanization: insert a stainless steel mandrel into ...

Embodiment 2

[0072] (1) The first kneading: put 2.0kg of NBR rubber, 4.0kg of EPDM rubber, 2.0kg of SBR rubber, 2.0kg of ECO rubber, 2.0kg of carbon black and 0.12kg of DTST into the internal mixer Refining for 15 minutes while controlling the system temperature below 100°C. Afterwards, the resultant was left to cool for more than 24 hours to stabilize the chemical properties.

[0073] (2) The second kneading: the dicumyl peroxide of the first kneading gain, 1.1kg blowing agent OBSH and 0.7kg was kneaded in an open mill for 27 minutes, while controlling the system temperature at 90 ℃ below to fully mix the three materials. Afterwards, the resultant was left to cool for more than 24 hours to stabilize the chemical properties. Afterwards, the second kneaded product is extruded into a hollow rubber rod by an extruder, and the temperature is controlled below 70°C during extrusion, and then left for more than 12 hours.

[0074] (3) Vulcanization: Insert a stainless steel mandrel into the hol...

Embodiment 3

[0077] (1) The first kneading: put 1.5kg of NBR rubber, 5.0kg of EPDM rubber, 1.5kg of SBR rubber, 2.0kg of ECO rubber, 1.0kg of carbon black and 0.12kg of DTST into the internal mixer Refining for 17 minutes while controlling the system temperature below 100°C. Afterwards, the resultant was left to cool for more than 24 hours to stabilize the chemical properties.

[0078] (2) The second kneading: kneading the dicumyl peroxide of the first kneading gain, 1.1kg blowing agent OBSH and 0.7kg in the open mill for 25 minutes, while controlling the temperature of the system at 90 ℃ below to fully mix the three materials. Afterwards, the resultant was left to cool for more than 24 hours to stabilize the chemical properties. Afterwards, the second kneaded product is extruded into a hollow rubber rod by an extruder, and the temperature is controlled below 70°C during extrusion, and then left for more than 12 hours.

[0079] (3) Vulcanization: insert a stainless steel mandrel into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com