High-safety lithium ion battery anode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied to battery electrodes, circuits, electrical components, etc., to achieve the effect of ensuring safety and avoiding thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

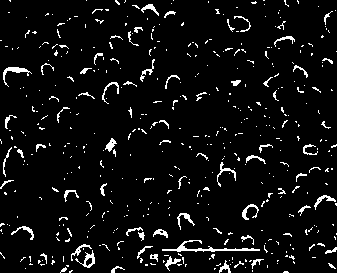

Image

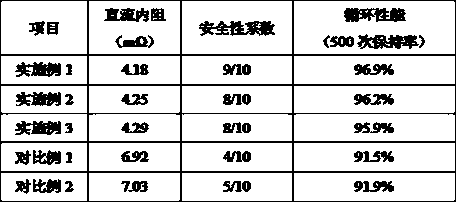

Examples

Embodiment 1

[0017] Step ① Binder configuration:

[0018] 70g of polyvinylidene fluoride, 19g of sodium carboxymethyl cellulose, 5g of polyvinyl alcohol, 5g of polyacrylic acid, and 1g of ethylene carbonate were mixed and added to 100ml of N-methylpyrrolidone, and mixed for 3 hours by a high-speed disperser to obtain a compound binder;

[0019] Step ② Dissolve 8g of melamine cyanurate and 2g of composite binder in 500ml of N-methylpyrrolidone and disperse evenly at high speed as functional coating solution A for future use;

[0020] At the same time, weigh 8g of asphalt and add it to 500ml of carbon tetrachloride to completely dissolve to obtain solution B; then add 0.3g of lithium metaaluminate and 0.3g of carbon nanotubes to 0.9g of composite binder and stir evenly before adding into solution B, and uniformly disperse through a high-speed disperser to obtain asphalt coating solution C;

[0021] Step ③: Add 100g of graphite to the functional coating solution A, stir evenly, and spray dr...

Embodiment 2

[0024] Step ① Binder configuration:

[0025] 60g polyvinylidene fluoride, 20g sodium carboxymethyl cellulose, 9.5g polyvinyl alcohol, 10g polyacrylic acid, 0.5g ethylene carbonate are mixed and added to 100ml of N-methylpyrrolidone, and mixed for 3 hours by a high-speed disperser get composite binder;

[0026] Step ② Dissolve 9g of pentaerythritol melamine phosphate and 1g of composite binder in 500ml of N-methylpyrrolidone and disperse evenly at high speed as functional coating solution A for future use;

[0027] At the same time, weigh 9g of asphalt and add it to 500ml of carbon tetrachloride to completely dissolve to obtain solution B; then add 0.1g of lithium metaaluminate and 0.1g of carbon nanotubes to 0.8g of composite binder and stir evenly before adding into solution B, and uniformly disperse through a high-speed disperser to obtain asphalt coating solution C;

[0028] Step ③: Add 100g of graphite to the functional coating liquid A, stir evenly, and spray drying met...

Embodiment 3

[0031] Step ① Binder configuration:

[0032] 80g polyvinylidene fluoride, 10g sodium carboxymethyl cellulose, 5g polyvinyl alcohol, 4g polyacrylic acid, 1g ethylene carbonate are mixed and added to 100ml of N-methylpyrrolidone, and mixed by a high-speed disperser for 3 hours to obtain a compound binder;

[0033] Step ② Sprinkle 8g of ammonium polyphosphate and 2g of composite binder in 500ml of N-methylpyrrolidone and disperse evenly at high speed as functional coating solution A for future use;

[0034] At the same time, weigh 8g of asphalt and add it to 500ml of carbon tetrachloride to completely dissolve to obtain solution B; then add 0.5g of lithium metaaluminate and 0.5g of carbon nanotubes to 0.1g of composite binder and stir evenly before adding into solution B, and uniformly disperse through a high-speed disperser to obtain asphalt coating solution C;

[0035] Step ③: Add 100g of graphite to the functional coating liquid A, stir evenly, and spray drying method, the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com