Cathode slurry of lithium ion batteries on production line and preparation method of cathode slurry

A lithium-ion battery, negative electrode slurry technology, applied in electrode manufacturing, battery electrodes, negative electrodes and other directions, can solve the problems of inappropriate viscosity, poor slurry dispersion, low production efficiency, etc., to achieve moderate viscosity, The effect of improving dispersion performance and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

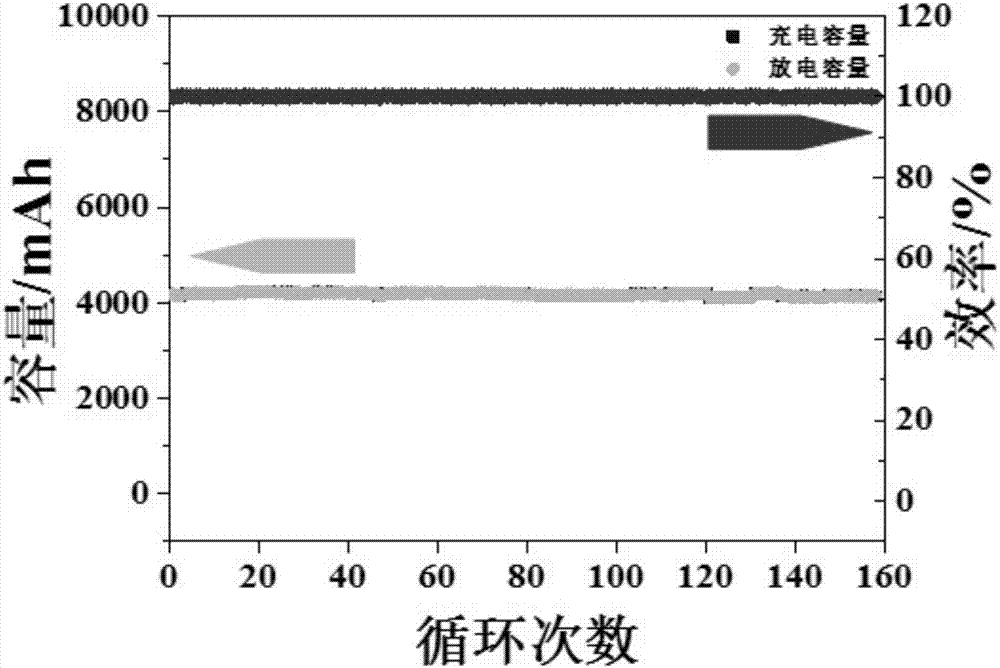

Image

Examples

Embodiment 1

[0029] a) Using artificial graphite as the negative electrode active material, weigh 100 g of the total raw materials according to the mass ratio of graphite: superconducting carbon black: lithium polyacrylate = 89.5:2:8.5. Pour the above-mentioned raw materials into a 500mL agate ball mill jar, and put in 20 agate beads each with a diameter of 5mm, 10mm, and 15mm. Adjust the rotational speed of the ball mill, and mix at a rotational speed of 150r / min for 20 minutes to preliminarily mix the raw materials uniformly, thereby obtaining the first mixture.

[0030] b) Next, add 120 mL of deionized water into the agate jar, and mix at a speed of 700 r / min for 0.5 h to obtain a second mixture.

[0031] c) Finally, increase the rotation speed to 900r / min and continue mixing for 6h. Obtain the negative electrode slurry of lithium ion battery.

[0032] The viscosity of the negative electrode slurry was tested for viscosity, and the test result was 3993cps, meeting the viscosity range ...

Embodiment 2

[0034] The difference between the preparation of the negative electrode slurry of this embodiment and that of Example 1 is:

[0035] In step a), the number of each kind of agate beads in the ball mill is 30; the rotating speed is 200r / min, and the time is 30min.

[0036] In step b), the amount of deionized water added is 130 mL; the rotation speed is 800 r / min, and the time is 45 min.

[0037] In step c), the rotating speed is 1000r / min, and the time is 6.5h.

[0038] After the viscosity test, the test result of the negative electrode slurry in this embodiment is 3735 cps, meeting the viscosity range requirement.

[0039] The rest are consistent with those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0041] The difference between the preparation of the negative electrode slurry of this embodiment and that of Example 1 is:

[0042] In step a), the number of each kind of agate beads in the ball mill is 40; the rotating speed is 300r / min, and the time is 30min.

[0043] In step b), the amount of deionized water added is 140 mL; the rotation speed is 900 r / min, and the time is 1 h.

[0044] In step c), the rotating speed is 1100r / min, and the time is 7h.

[0045] After a viscosity test, the test result of the negative electrode slurry in this embodiment is 3562 cps, meeting the viscosity range requirement.

[0046] The rest are consistent with those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com