Preparation method of polydopamine-coated sodium ion battery positive electrode material

A technology for sodium ion batteries and positive electrode materials, which is applied in the direction of battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of poor integrity of coating materials, excess gas discharge, and impact on conductivity, etc., to improve cycle performance, coating Thin layer and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

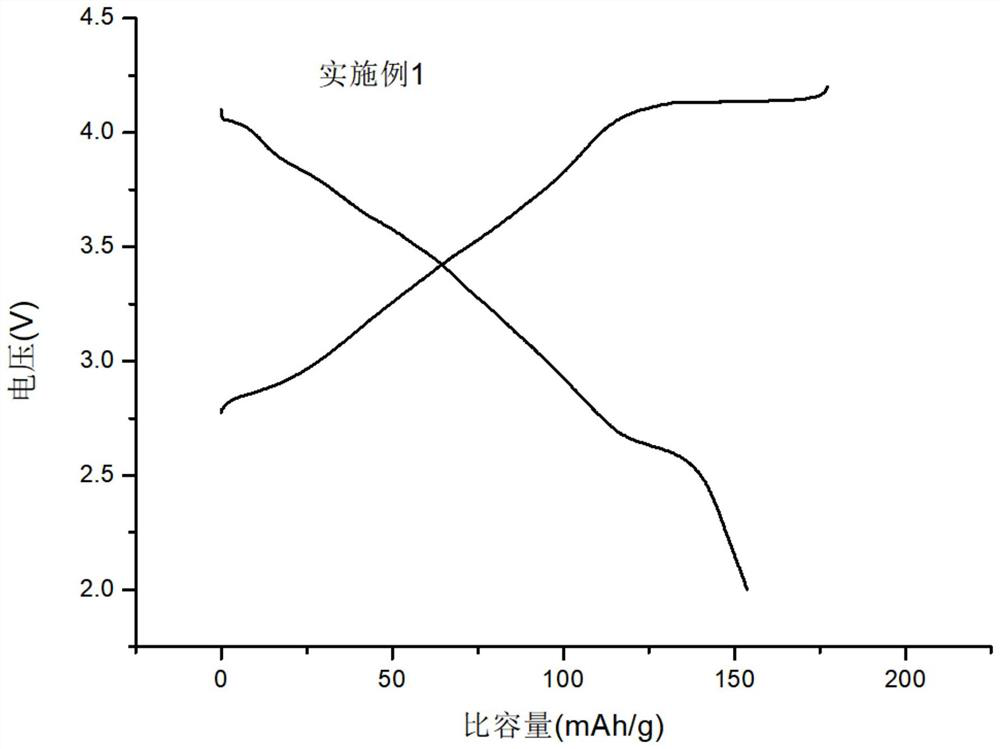

Embodiment 1

[0047] A preparation method of a polydopamine-coated sodium ion battery positive electrode material, comprising:

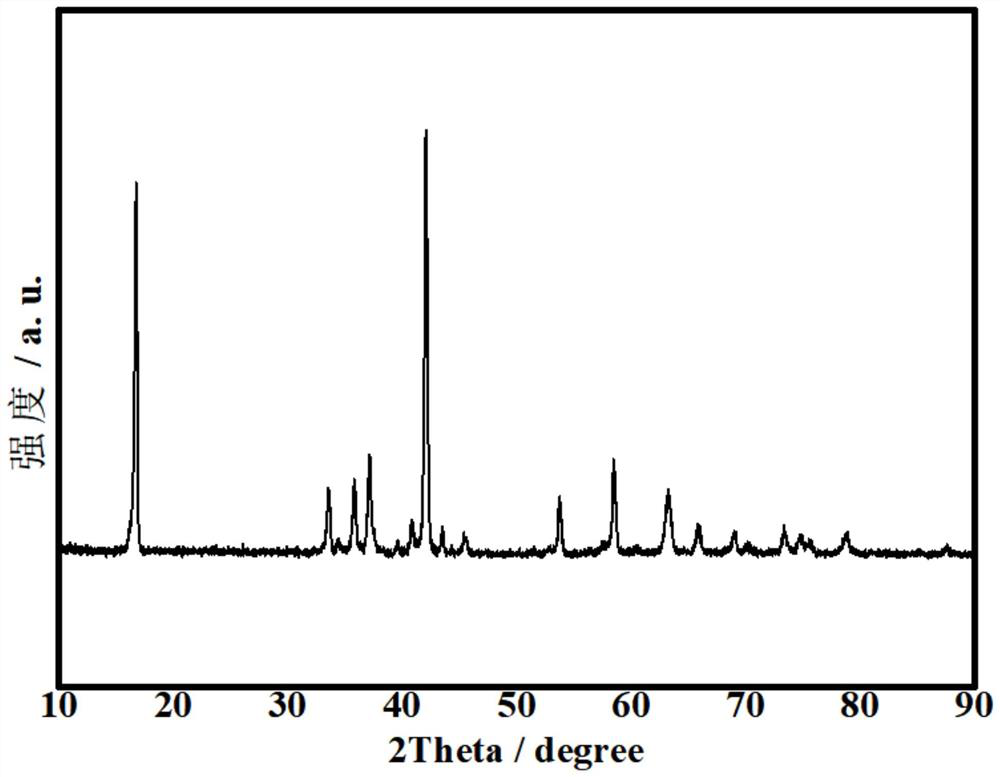

[0048] Step 1, using a high-speed mixer, the general formula synthesized by the co-precipitation method is Ni 1 / 3 Fe 1 / 3 mn 1 / 3 (OH) 2 The precursor and sodium carbonate were mixed at a molar ratio of 1:1.05, kept in a muffle furnace at 1000°C for 15 hours, the heating rate was 5°C / min, cooled to room temperature and crushed, then placed in a muffle furnace for calcination at 1000°C for 5 hours , crushed and sieved after cooling down to obtain NaNi 1 / 3 Fe 1 / 3 mn 1 / 3 o 2 Cathode material.

[0049] Step 2. Disperse the prepared positive electrode material in N-methyl-2-pyrrolidone, the solid-to-liquid ratio is 1:10, the ambient air humidity requirement is ≤15%, the temperature is kept at 25±5°C, and the mixture is dispersed at high speed for 15 minutes. Solution A, add 5wt% dopamine hydrochloride, stir and react for 24h in dry air at a stirring rate of 450rp...

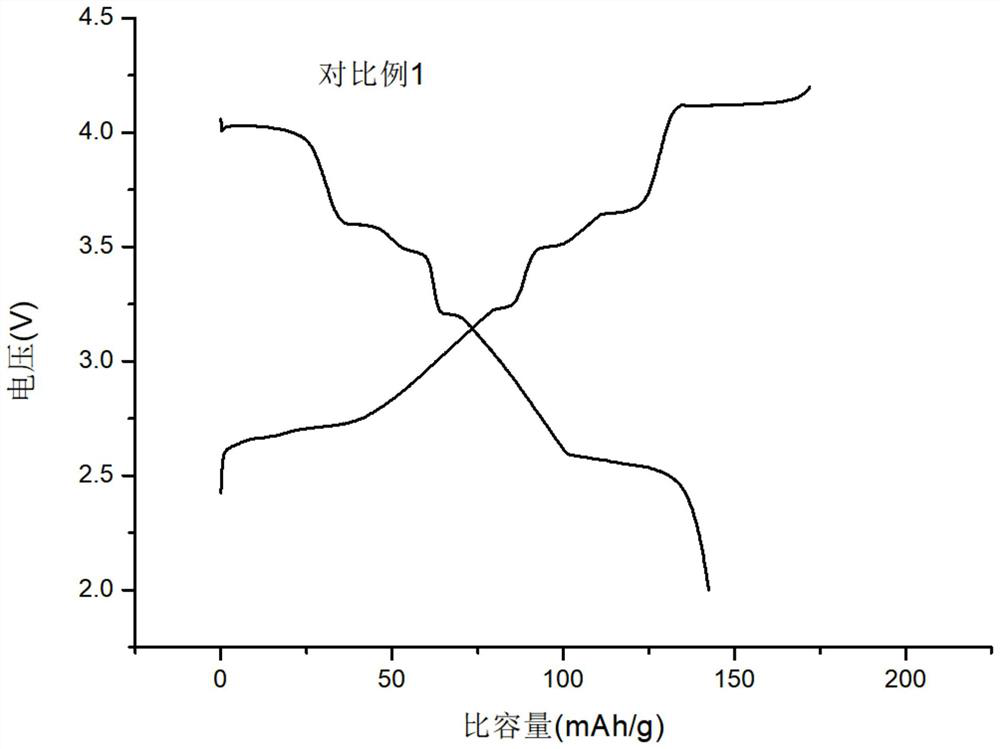

Embodiment 2

[0058] Step 1, using a high-speed mixer, the general formula synthesized by the co-precipitation method is Mg 1 / 3 Fe 1 / 3 mn 1 / 3 (OH) 2 The precursor and sodium carbonate were mixed at a molar ratio of 1:1.05, kept in a muffle furnace at 1000°C for 15 hours, the heating rate was 5°C / min, cooled to room temperature and crushed, then placed in a muffle furnace for calcination at 1000°C for 5 hours , crushed and sieved after cooling down to obtain NaMg 1 / 3 Fe 1 / 3 mn 1 / 3 o 2 Cathode material.

[0059] Step 2. Disperse the prepared positive electrode material in N-methyl-2-pyrrolidone, the solid-to-liquid ratio is 1:10, the ambient air humidity is required to be ≤15%, the temperature is kept at 25±5°C, and the mixture is dispersed at high speed for 15 minutes. Solution A, add 5wt% dopamine hydrochloride, stir and react for 24h in dry air at a stirring rate of 450rpm.

[0060] Step 3. After the reaction is completed, the mixed solution B is obtained, the mixed solution B is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com