Lithium titanate composite anode material and preparation method thereof

A negative electrode material, lithium titanate technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low lithium ion and electron conductivity, limit the practical application of materials, cycle performance degradation, etc., and achieve cycle life. Suppression, low cost, effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: The lithium titanate composite negative electrode material is prepared by the following process steps.

[0034] According to the Al / Ti molar ratio of 0.001 and Si / Ti molar ratio of 0.001, completely dissolve 2.22g of aluminum isopropoxide in 1.5L of absolute ethanol solution, and add 1kg of spinel lithium titanate material (pure lithium titanate) , 2000r / min high-speed dispersion for 6h; then add 1.66g of methyl orthosilicate, continue 2000r / min high-speed dispersion for 4h; finally dry at 100°C, and then sinter at 800°C for 10h, you can get the lithium titanate composite Negative material.

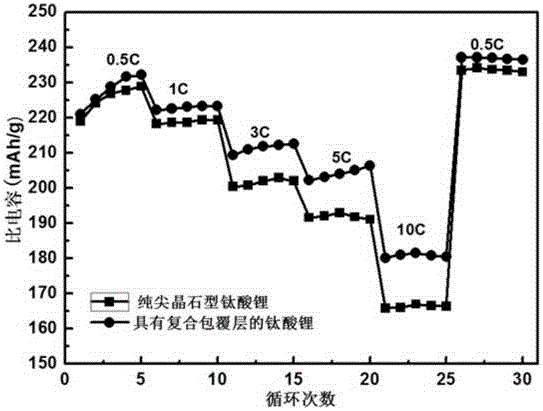

[0035] figure 1 is the XRD spectrum of the lithium titanate composite negative electrode material, from figure 1 It can be seen from the figure that the XRD pattern of the prepared lithium titanate composite negative electrode material corresponds well to the JCPDS card (No.49-0207) of the standard lithium titanate, indicating that the modified lithium titanate comp...

Embodiment 2

[0038] Embodiment 2: The lithium titanate composite negative electrode material is prepared by the following process steps.

[0039] According to the Al / Ti molar ratio of 0.005 and Si / Ti molar ratio of 0.005, completely dissolve 13.4g of aluminum sec-butoxide in 1.5L of absolute ethanol solution, add 1kg of spinel lithium titanate material, and disperse at a high speed of 2000r / min 4h; then add 11.3g ethyl orthosilicate, continue high-speed dispersion at 2000r / min for 6h; finally dry at 100°C, and sinter at 750°C for 10h to obtain the lithium titanate composite negative electrode material.

[0040] Figure 4 It is the HR-TEM photo of the lithium titanate composite negative electrode material; from Figure 4 It can be seen from the figure that there is an obvious coating layer on the surface of the lithium titanate composite negative electrode material, and the thickness of the coating layer is about 11-12 nm.

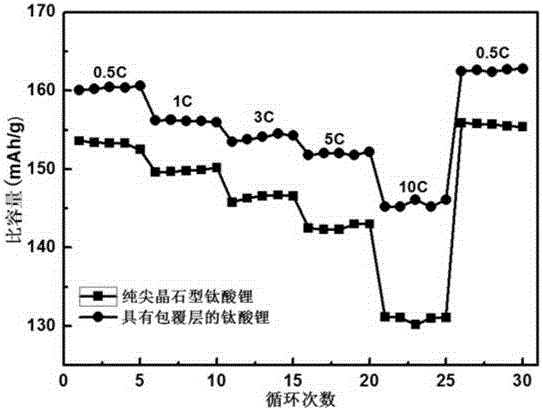

[0041] Electrochemical performance test: the test method is the ...

Embodiment 3

[0043] Embodiment 3: The lithium titanate composite negative electrode material is prepared by the following process steps.

[0044] According to the Al / Ti molar ratio of 0.001 and Si / Ti molar ratio of 0.03, completely dissolve 2.22g of aluminum isopropoxide in 1.5L of isopropanol solution, add 1kg of spinel lithium titanate material, and disperse at a high speed of 3000r / min 8h; then add 86.4g propyl orthosilicate, continue high-speed dispersion at 3000r / min for 4h; finally dry at 100°C and sinter at 730°C for 8h to obtain the lithium titanate composite negative electrode material.

[0045] Figure 5 It is the HR-TEM photo of the lithium titanate composite negative electrode material; from Figure 5 It can be seen that there is an obvious coating layer on the surface of the lithium titanate composite negative electrode material, and the thickness of the coating layer is about 6-7nm.

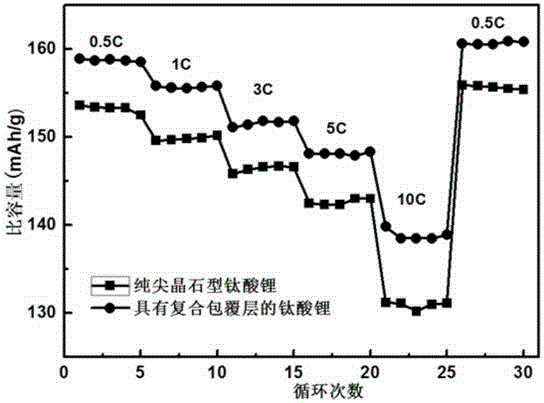

[0046] Electrochemical performance test: the test method is the same as in Example 1. Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com