Bismuth vanadate functional ceramic and preparation method thereof

A technology of functional ceramics and bismuth vanadate, which is applied in the field of bismuth vanadate functional ceramics and its preparation, can solve the problems that bismuth vanadate is difficult to sinter into porcelain, achieve high density, ensure conversion rate and production efficiency, and suppress volatilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

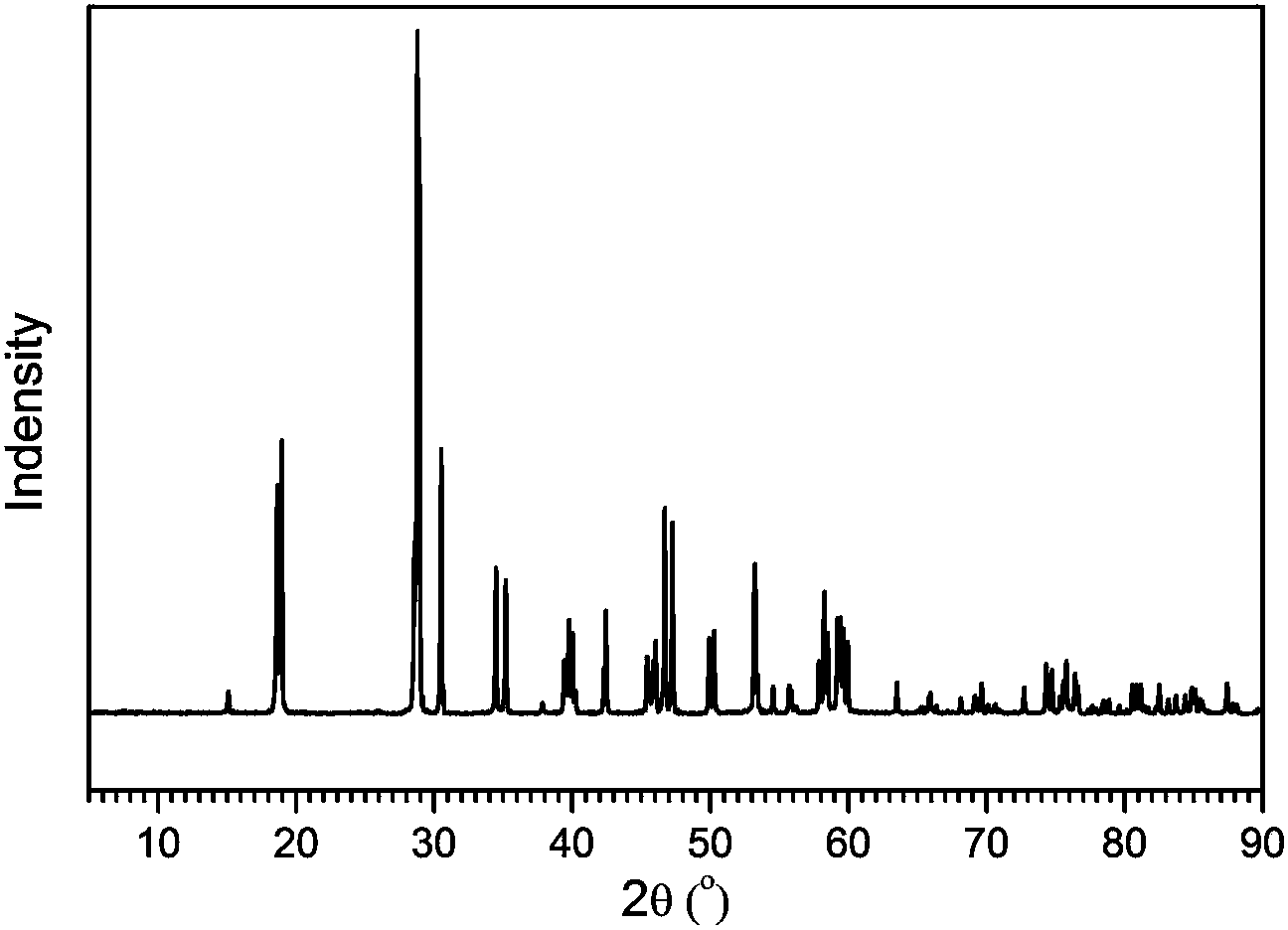

[0021] A kind of bismuth vanadate functional ceramics, its chemical composition is BiVO 4 , The density is over 97%, the dielectric constant is 60, and the dielectric loss is <0.005. The ceramic has physical properties such as ion conductivity, ferroelasticity, and photochromic change, and has good dielectric properties, and is an ideal functional material.

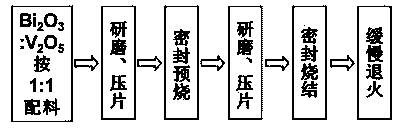

[0022] The preparation method of described bismuth vanadate functional ceramics is, with Bi 2 o 3 and V 2 o 5 Powder as raw material, Bi 2 o 3 and V 2 o 5 After the powder is mixed according to the molar ratio of 1:1, it is mixed and put into the grinding equipment, and it is manually ground for 5 hours. When grinding, absolute ethanol is used as a solvent to keep the particles uniform and not to generate powder dust. The amount of water ethanol is about 5% of the powder mass. It is guaranteed that it can be volatilized completely after grinding and will not remain in the powder. Dry the ground powder and press ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com