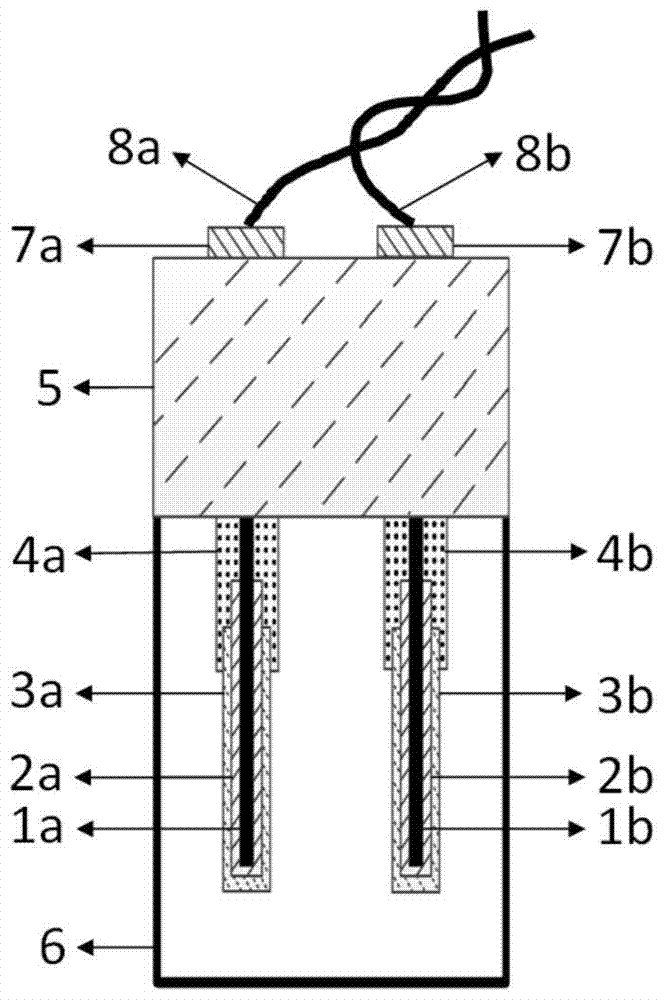

All-solid-state acetylcholine sensor and preparation method thereof

An acetylcholine and all-solid-state technology, applied in the field of biosensors, can solve the problems of poor real-time performance of acetylcholine, cumbersome experimental pretreatment, and difficult storage, and achieve the effects of rapid response, stable work, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

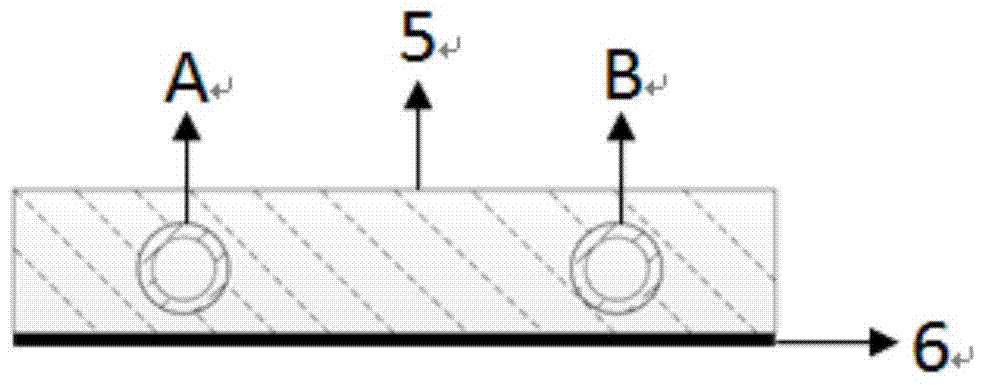

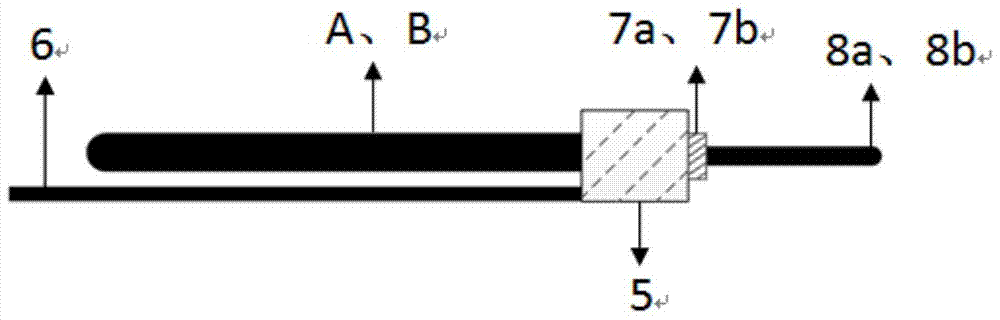

Embodiment 1

[0066] (1) Immerse one end of two gold wires with a diameter of 0.1mm into a suspension of alumina powder with a diameter of 0.5 microns, the concentration of the alumina suspension is 80g / L, use ultrasonic vibration to polish for 10 minutes, and rinse with deionized water; Then immerse the same end of the gold wire into a suspension of alumina powder with a diameter of 50 nanometers, the concentration of the alumina suspension is 80g / L, use ultrasonic vibration to polish for 10 minutes, and rinse with deionized water; Soak in dilute sulfuric acid solution for 3 minutes, rinse with deionized water;

[0067] (2) adopting 0.3% sodium carboxymethylcellulose solution as surfactant active aqueous solution to put into drying oven after gold wire is cleaned;

[0068] (3) Disperse poly 3,4-hexylenedioxythiophene / polystyrene sulfonic acid (PEDOT / PSS, Clevios P from H.C. Starck, Germany, CAS No.155090-83-8) in deionized water to form a suspension Liquid, the ratio of PEDOT / PSS:H 2 O...

Embodiment 2

[0078] (1) Immerse one end of two platinum wires with a diameter of 0.1mm into a suspension of alumina powder with a diameter of 0.5 microns, the concentration of the alumina suspension is 80g / L, use ultrasonic vibration to polish for 10 minutes, and rinse with deionized water; Then immerse the same end of the gold wire into a suspension of alumina powder with a diameter of 50 nanometers, the concentration of the alumina suspension is 80g / L, use ultrasonic vibration to polish for 10 minutes, and rinse with deionized water; Soak in dilute sulfuric acid solution for 3 minutes, rinse with deionized water;

[0079] (2) Adopting 0.3% sodium carboxymethylcellulose solution as a surfactant active aqueous solution to clean the platinum wire and put it into a dry box for drying;

[0080] (3) Mix aniline and 2,5 dimethoxybenzene to form a copolymer, and the mass ratio of the two is aniline:2,5 dimethoxybenzene=5:1. Then prepare a DMF saturated solution of soluble polyaniline. Dip the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com