Composite binder for solid-state lithium batteries and preparation method thereof

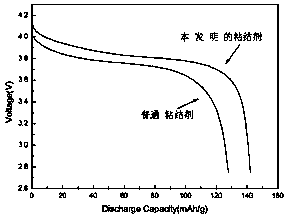

A binder, solid lithium technology, applied in the field of electric energy, can solve the problems of poor adhesion, weak adhesion, easy falling off of battery materials, etc., to reduce internal resistance, improve rate performance and cycle life, adhesion ability stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the composite binder for solid-state lithium batteries of the present invention comprises the following steps:

[0019] Step 1: Dissolve the high molecular polymer in the organic solvent, and completely dissolve the polymer in the solvent under the condition of heating and stirring. The mass of the high molecular polymer accounts for 1%-20% of the total mass of the glue. The heating temperature range 20℃-80℃;

[0020] Step 2: Add lithium salt to the homogeneous solution formed in step 1, and stir for 0.5h-3h, so that the lithium salt is completely dissolved in the solution, and the mass of the lithium salt accounts for 1%-20% of the total mass of the glue solution;

[0021] Step 3: Add the inorganic ceramic fast ion conductor on the basis of step 3, and use stirring or ultrasonic dispersion method to uniformly disperse the inorganic ceramic particles in the glue solution. The mass of the inorganic ceramic fast ion conductor accounts for 0.5%-10...

Embodiment 1

[0030] Dissolve 0.2g PVDF in 8ml NMP, heat at 50℃ for 1h under stirring condition to dissolve PVDF completely; then add 0.15g LiPF to the solution 6 , stirring for 0.5h to make LiPF 6 Completely dissolved; then add 0.08g LLZO, disperse LLZO uniformly in the solution under ultrasonic conditions, heat the mixed solution at 50°C for 6h under ultrasonic conditions, and after the color of the solution becomes dark red, stop heating and ultrasonication.

Embodiment 2

[0032] Dissolve 0.3 g of PVDF-HFP in 10 ml of DMF, and heat at 60 °C for 0.5 h under stirring conditions to completely dissolve PVDF-HFP; then add 0.3 g of LiTFSI to the solution, heat and stir for 0.5 h to completely dissolve the lithium salt; Add 0.2 g of LAGP to the mixed solution under mechanical stirring, and after fully stirring, heat the mixed solution at 60°C for 12 h under stirring, and stop heating and stirring after the color of the mixed solution changes to dark brown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com