Solid electrolyte with double conducting ion networks and preparation method of solid electrolyte

A solid electrolyte and ionic network technology, applied in the field of solid electrolyte and its preparation, can solve the problems of low electrical conductivity and poor mechanical properties, and achieve the effects of simple preparation process, good flexibility and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

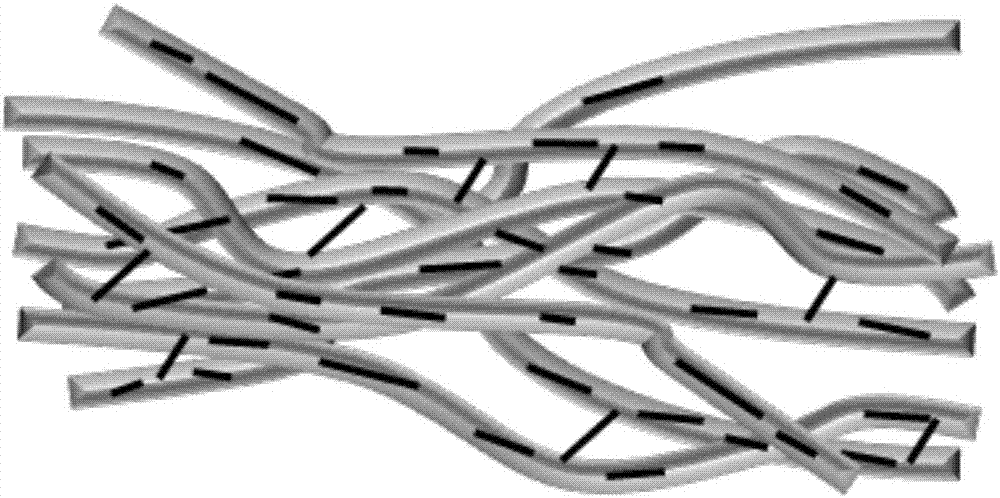

[0023] (1) Lithium perchlorate and PAN (mass ratio 0.1: 1) are put into conical flask and add appropriate amount of solvent, be made into the spinning solution of high polymer mass fraction 10%; Then mass fraction is 5% ( The nanorods made of the inorganic solid electrolyte whose total mass is the mass of PAN and the filler) are added to the above solution, and fully stirred to make the mixture uniform.

[0024] (2) Electrospinning is carried out under the conditions of an injection speed of 1ml / h, a spinning voltage of 20kv, and the use of a roller to receive (roller speed 1000r / min);

[0025] (3) After spinning, put the electrospun film into an oven, and dry it at 60°C for 3-48 hours to completely volatilize the solvent. The resulting film was used for later use.

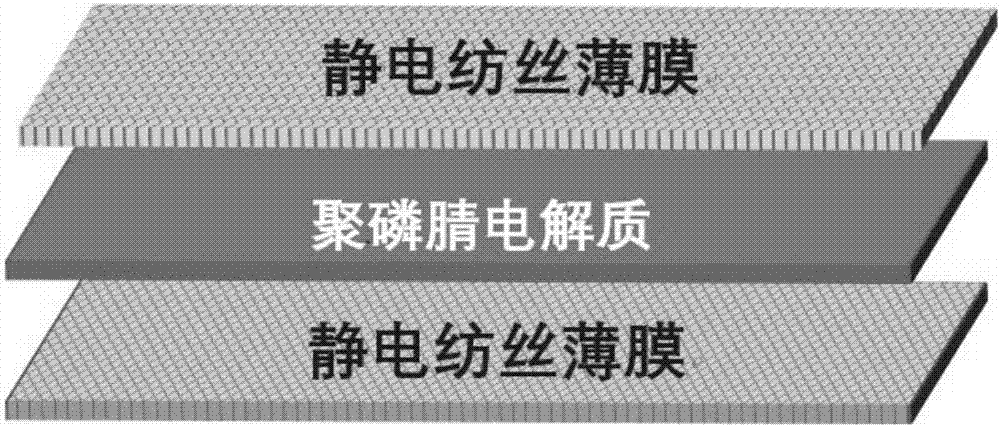

[0026] (4) Dissolve a certain amount of linear polyphosphazene (PDCP) in a quantitative THF solution, add Diethylene Glycol Monomethyl Ether (Diethylene Glycol Monomethyl Ether) to it after the PDCP is fully diss...

Embodiment 2

[0034] (1) Lithium perchlorate and PAN (mass ratio 0.1:1) are put into conical flask and add appropriate amount of solvent, be made into the spinning solution of high polymer mass fraction 10%; Then mass fraction is 15% ( The nanorods made of the inorganic solid electrolyte whose total mass is the mass of PAN and the filler) are added to the above solution, and fully stirred to make the mixture uniform.

[0035] (2) Electrospinning is carried out under the conditions of an injection speed of 1ml / h, a spinning voltage of 20kv, and the use of a roller to receive (roller speed 1000r / min);

[0036] (3) After spinning, put the electrospun film into an oven, and dry it at 60°C for 3-48 hours to completely volatilize the solvent. The resulting film was used for later use.

[0037] (4) Dissolve a certain amount of linear polyphosphazene (PDCP) in a quantitative THF solution, add Diethylene Glycol Monomethyl Ether (Diethylene Glycol Monomethyl Ether) to it after the PDCP is fully diss...

Embodiment 3

[0045] (1) Lithium perchlorate and PAN (mass ratio 0.1:1) are put into conical flask and add appropriate amount of solvent, be made into the spinning solution of high polymer mass fraction 10%; Then mass fraction is 25% ( The nanorods made of the inorganic solid electrolyte whose total mass is the mass of PAN and the filler) are added to the above solution, and fully stirred to make the mixture uniform.

[0046] (2) Electrospinning is carried out under the conditions of an injection speed of 1ml / h, a spinning voltage of 20kv, and the use of a roller to receive (roller speed 1000r / min);

[0047] (3) After spinning, put the electrospun film into an oven, and dry it at 60°C for 3-48 hours to completely volatilize the solvent. The resulting film was used for later use.

[0048] (4) Dissolve a certain amount of linear polyphosphazene (PDCP) in a quantitative THF solution, add Diethylene Glycol Monomethyl Ether (Diethylene Glycol Monomethyl Ether) to it after the PDCP is fully diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com