A kind of multifunctional lubricating oil additive and its application

A lubricating oil additive, multi-functional technology, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve the problems of single function of lubricating oil additives, unable to meet the requirements of use, etc., to improve anti-wear and extreme pressure, enhance mutual effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of multifunctional lubricating oil additive, described additive is made up of the raw material of following parts by weight:

[0034] 50 parts of morpholine ionic liquid;

[0035] 0.8 parts of detergent;

[0036] 1.2 parts of antirust agent;

[0037] Antioxidant 7 parts; and

[0038] Foam inhibitor 0.2 parts.

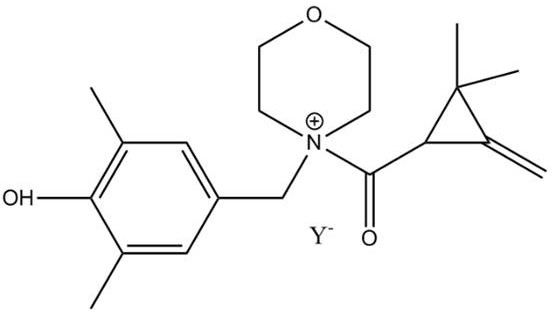

[0039] The morpholine ionic liquid has the following structural formula:

[0040]

[0041] Among them, Y - from BF 4- .

[0042] The preparation method of described morpholine ionic liquid is as follows:

[0043] Step S1: After mixing 2,2-dimethyl-3-vinylcyclopropanecarbonyl chloride and 2,6-dimethyl-4-(4-morpholinylmethyl)phenol in a molar ratio of 1.05:1 Microwave radiation was heated for 1 min, and then stirred for 3 min to obtain chlorinated 2,2-dimethyl-3-vinylcyclopropanecarbonyl-2,6-dimethyl-4-(4-morpholinomethyl)phenol;

[0044] Step S2: the chlorinated 2,2-dimethyl-3-vinylcyclopropanecarbonyl-2,6-dimethyl-4-(4-morpholinomethyl)phenol a...

Embodiment 2

[0053] A kind of multifunctional lubricating oil additive, described additive is made up of the raw material of following parts by weight:

[0054] 80 parts of morpholine ionic liquid;

[0055] 3.5 parts of detergent;

[0056] 1.8 parts of antirust agent;

[0057] Antioxidant 12 parts; and

[0058] Foam inhibitor 1.6 parts.

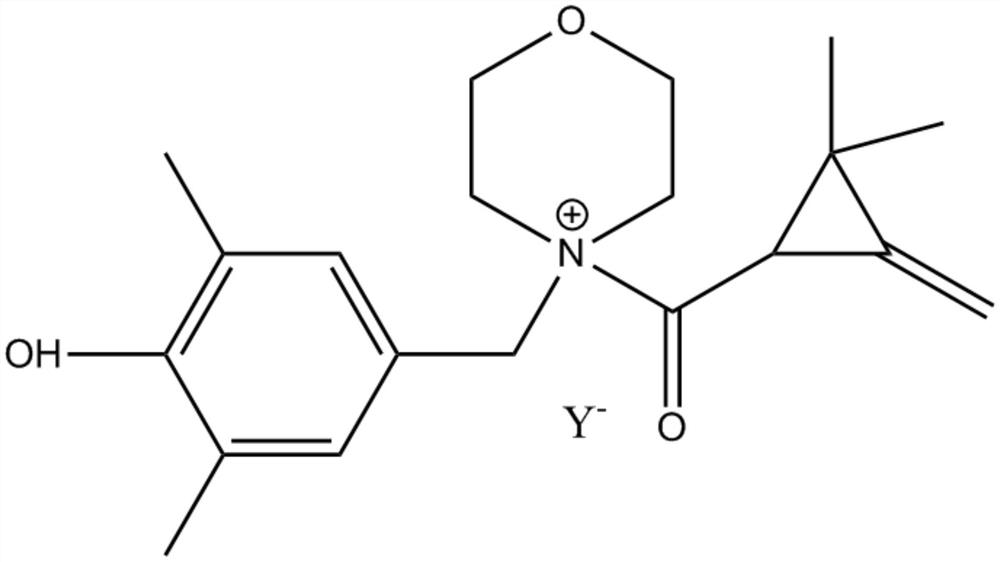

[0059] Preferably, the morpholine ionic liquid has the following structural formula:

[0060]

[0061] Among them, Y - from PF 6- .

[0062] The preparation method of described morpholine ionic liquid is as follows:

[0063] Step S1: After mixing 2,2-dimethyl-3-vinylcyclopropanecarbonyl chloride and 2,6-dimethyl-4-(4-morpholinylmethyl)phenol at a molar ratio of 1.1:1 Microwave radiation was heated for 3 minutes, and then stirred for 8 minutes to obtain chlorinated 2,2-dimethyl-3-vinylcyclopropanecarbonyl-2,6-dimethyl-4-(4-morpholinomethyl)phenol;

[0064] Step S2: the chlorinated 2,2-dimethyl-3-vinylcyclopropanecarbonyl-2,6-dimethyl-4-(4-morphol...

Embodiment 3

[0073] A kind of multifunctional lubricating oil additive, described additive is made up of the raw material of following parts by weight:

[0074] 100 parts of morpholine ionic liquid;

[0075] 7.5 parts of detergent;

[0076] 2.6 parts of antirust agent;

[0077] Antioxidant 16 parts; and

[0078] Foam inhibitor 3.8 parts.

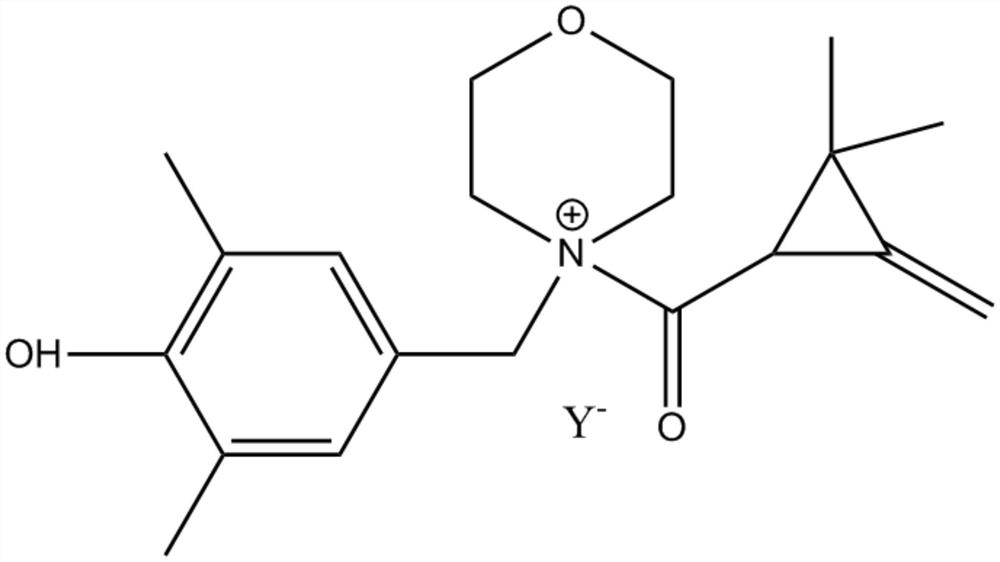

[0079] Preferably, the morpholine ionic liquid has the following structural formula:

[0080]

[0081] Among them, Y - from BF 4- .

[0082] The preparation method of described morpholine ionic liquid is as follows:

[0083] Step S1: After mixing 2,2-dimethyl-3-vinylcyclopropanecarbonyl chloride and 2,6-dimethyl-4-(4-morpholinylmethyl)phenol in a molar ratio of 1.2:1 Microwave radiation was heated for 5 minutes, and then stirred for 10 minutes to obtain chlorinated 2,2-dimethyl-3-vinylcyclopropanecarbonyl-2,6-dimethyl-4-(4-morpholinomethyl)phenol;

[0084] Step S2: the chlorinated 2,2-dimethyl-3-vinylcyclopropanecarbonyl-2,6-dimethyl-4-(4-mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com