Double-network double-ion conductive transparent electronic skin sensor material and preparation method thereof

A conductive transparent, electronic skin technology, applied in the direction of sensors, diagnosis, applications, etc., can solve the problems of poor sensing performance and achieve the effect of enhancing conductive sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Preparation of anthocyanin-coated nanocellulose to adsorb iron ions:

[0020] First, weigh 10 g of 0.5 wt% nanocellulose in a 100 ml beaker, and adjust the pH to 8. Then add 0.02g anthocyanin and stir the reaction for 6h at room temperature. Then add 0.01g Fe 3+ Mix and stir for 1 h at room temperature. Nanocellulose / Anthocyanin / Fe can be obtained after centrifugation 3+ Complex.

[0021] (2) Preparation of dual-network dual-ion conductive transparent electronic skin sensor materials:

[0022] Weigh 0.3g of guar gum and add it to 10ml of glycerin aqueous solution (the volume ratio of glycerol to water is 1:4), and stir at 25°C to completely dissolve the guar gum. Then the above nanocellulose / anthocyanidin / Fe 3+ The complex was added to the guar gum solution, stirred for 1 h to make it evenly mixed, and ultrasonically treated for 0.5 h, and then 5 mL of 4 wt% borax solution was slowly added dropwise to make the guar gum solution form a hydrogel.

Embodiment 2

[0024] (1) Preparation of anthocyanin-coated nanocellulose to adsorb iron ions:

[0025] First, weigh 15g of 0.5wt% nanocellulose in a 100ml beaker, and adjust the pH to 8. Then add 0.03g anthocyanin and stir the reaction for 6h at room temperature. Then add 0.01g Fe 3+ Mix and stir for 1 h at room temperature. Nanocellulose / Anthocyanin / Fe can be obtained after centrifugation 3+ Complex.

[0026] (2) Preparation of dual-network dual-ion conductive transparent electronic skin sensor materials:

[0027] Weigh 0.45g of guar gum and add it to 10ml of glycerin aqueous solution (the volume ratio of glycerol to water is 1:4), and stir at 25°C to completely dissolve the guar gum. Then the above nanocellulose / anthocyanidin / Fe 3+ The complex was added to the guar gum solution, stirred for 1 h to make it evenly mixed, and ultrasonically treated for 0.5 h, and then 5 mL of 4 wt% borax solution was slowly added dropwise to make the guar gum solution form a hydrogel.

Embodiment 3

[0029] (1) Preparation of anthocyanin-coated nanocellulose to adsorb iron ions:

[0030] First, weigh 20g of 0.5wt% nanocellulose in a 100ml beaker, and adjust the pH to 8. Then add 0.04g anthocyanin and stir the reaction for 6h at room temperature. Then add 0.01g Fe 3+ Mix and stir for 1 h at room temperature. Nanocellulose / Anthocyanin / Fe can be obtained after centrifugation 3+ Complex.

[0031] (2) Preparation of dual-network dual-ion conductive transparent electronic skin sensor materials:

[0032] Weigh 0.6g of guar gum and add it to 10ml of glycerin aqueous solution (the volume ratio of glycerol to water is 1:4), and stir at 25°C to completely dissolve the guar gum. Then the above nanocellulose / anthocyanidin / Fe 3+ The complex was added to the guar gum solution, stirred for 1 h to make it evenly mixed, and ultrasonically treated for 0.5 h, and then 5 mL of 4 wt% borax solution was slowly added dropwise to make the guar gum solution form a hydrogel.

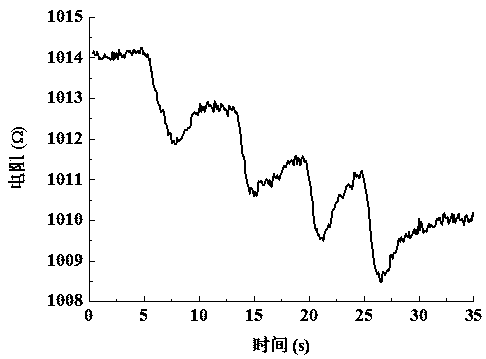

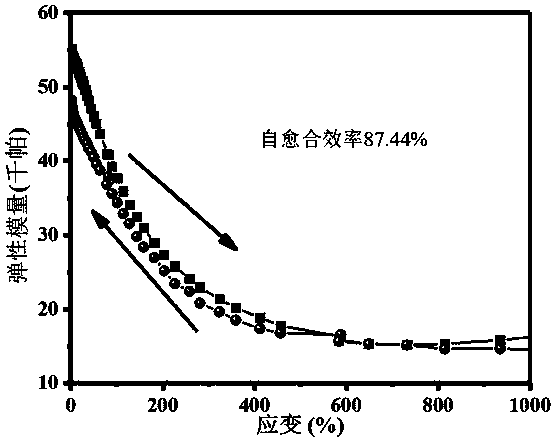

[0033] Perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com