Lithium-ion battery positive pole piece and preparation method thereof

A lithium-ion battery and positive pole piece technology, which is applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of affecting the electrical properties such as material magnification, the reduction of material conductivity, and the poor comprehensive electrical properties, so as to improve the High-temperature cycle life and high-temperature storage capacity retention, increased electrical conductivity, and improved overall electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

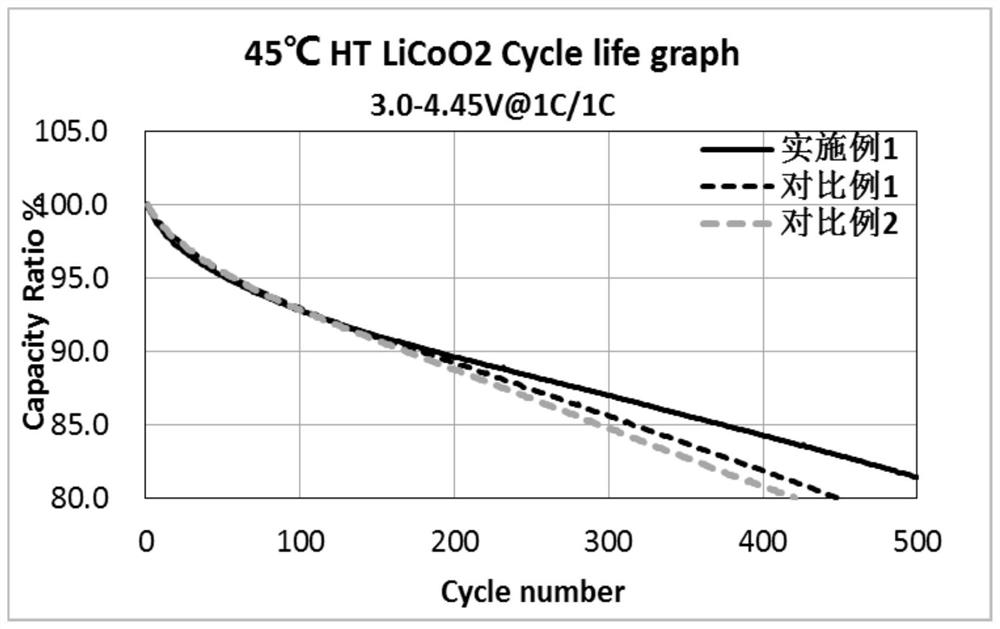

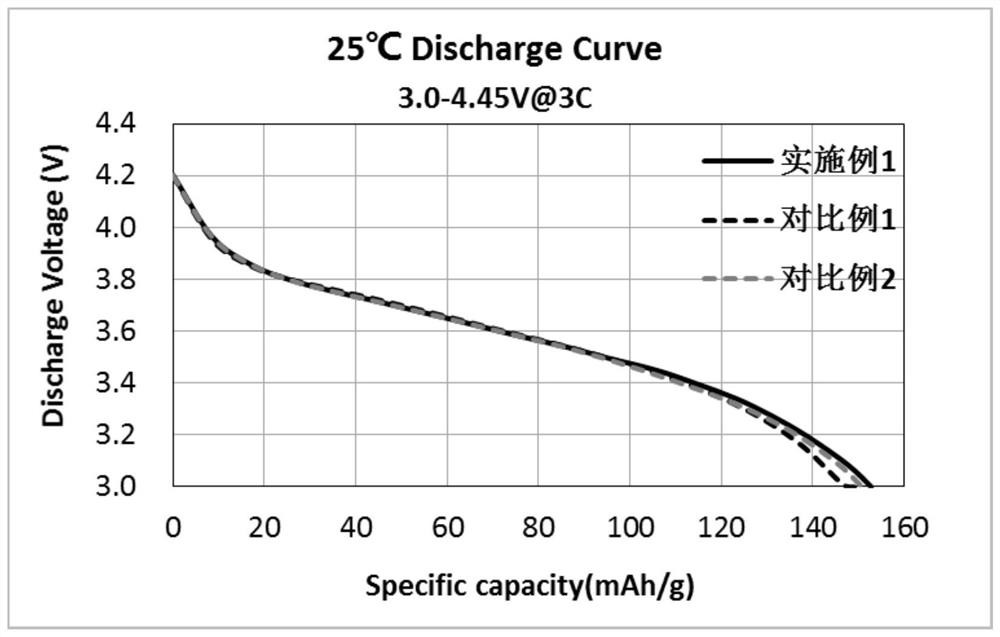

Embodiment 1

[0032] A lithium ion battery positive electrode sheet of the present invention comprises a current collector aluminum foil and a positive electrode active material layer coated on the surface of the current collector aluminum foil, wherein the positive electrode active material layer is mainly composed of a positive electrode active material lithium cobaltate, a conductive agent carbon black SP , additives (Al(PO 3 ) 3 and LiPO 3 ) and binder PVDF 900, wherein the mass content of lithium cobaltate is 95%, the mass content of conductive agent SP is 2%, Al(PO 3 ) 3 and LiPO 3 The mass content is 0.5% (ie Al(PO 3 ) 3 and LiPO 3 The mass ratio of the two additives is 1:1), and the mass content of the binder PVDF 900 is 2%.

[0033] The preparation method of the lithium-ion battery positive pole piece of the present embodiment comprises the following steps:

[0034] (1) Homogenization: Add 23.8g conductive agent SP to the NMP glue of PVDF 900 adhesive (the PVDF glue is 297....

Embodiment 2

[0040] A lithium ion battery positive electrode sheet of the present invention comprises a current collector aluminum foil and a positive electrode active material layer coated on the surface of the current collector aluminum foil, wherein the positive electrode active material layer is mainly composed of a positive electrode active material lithium cobaltate, a conductive agent carbon black SP , additives (Al(PO 3 ) 3 and LiPO 3 ) and binder PVDF 900, wherein the mass content of lithium cobaltate is 93.2%, the mass content of conductive agent SP is 1.9%, Al(PO 3 ) 3 The mass content is 1.5% and LiPO 3 The mass content is 1.5% (ie Al(PO 3 ) 3 and LiPO 3 The mass ratio of the two additives is 1:1), and the mass content of the binder PVDF 900 is 1.9%.

[0041] The preparation method of the lithium-ion battery positive pole piece of the present embodiment comprises the following steps:

[0042] (1) Homogenization: Add 23.3g conductive agent SP to the NMP glue of PVDF 900 ...

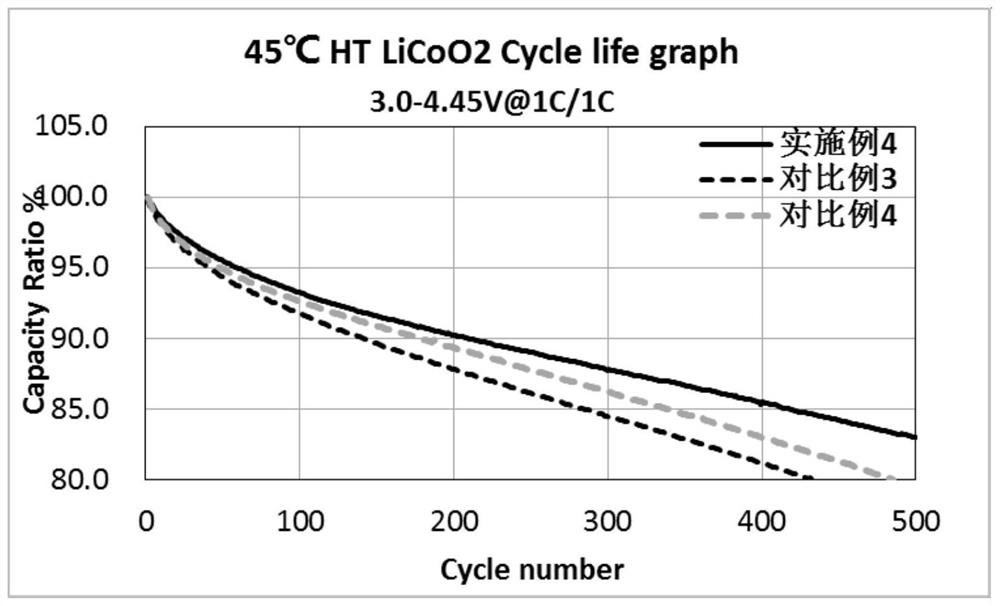

Embodiment 3

[0046] A lithium ion battery positive electrode sheet of the present invention comprises a current collector aluminum foil and a positive electrode active material layer coated on the surface of the current collector aluminum foil, wherein the positive electrode active material layer is mainly composed of a positive electrode active material lithium cobaltate, a conductive agent carbon black SP , additives (Al(PO 3 ) 3 and LiPO 3 ) and binder PVDF 900, wherein the mass content of lithium cobaltate is 94%, the mass content of conductive agent SP is 2%, Al(PO 3 ) 3 and LiPO 3 The mass content is 1% (ie Al(PO 3 ) 3 and LiPO 3 The mass ratio of the two additives is 1:1), and the mass content of the binder PVDF 900 is 2%.

[0047] The preparation method of the lithium-ion battery positive pole piece of the present embodiment comprises the following steps:

[0048] (1) Homogenization: Add 23.5g conductive agent SP to the NMP glue of PVDF 900 adhesive (the PVDF glue is 294.0g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com