Electrochromic dimming thin film and preparation method thereof

An electro-dimming and thin-film technology, which is applied in the field of dimming films, can solve problems such as lack of dimming effect, blurred imaging, and influence of light transmittance, and achieve excellent linear light transmittance, promote electrical conductivity, The effect of excellent dimming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

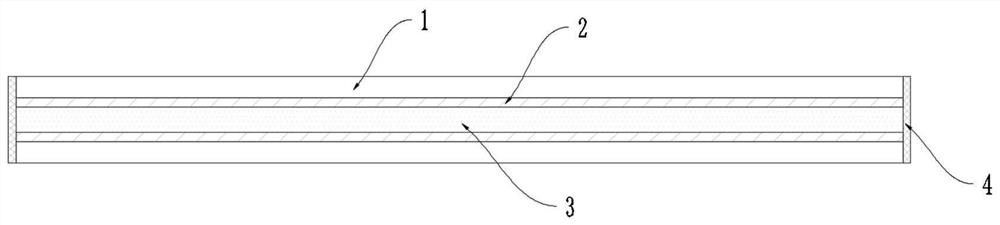

[0033] see figure 1 , the present embodiment provides that the liquid crystal film 3 is formed by sandwiching and rolling the liquid crystal layer by two substrates 1, and the liquid crystal layer is fully homogenized and densely formed, and the ITO conductive film layer 2 and the liquid crystal film 3 are used to adjust light and conduct electricity together to improve The conductive properties of the dimming film can reduce the driving voltage and promote energy saving. The outer substrate 1 can provide reliable protection for the conductive structure of the inner layer. The liquid optical glue LOCA4 is used to coat the edge of the substrate 1 and the liquid crystal film 3 to promote the tight connection of the structure. Good strength.

Embodiment 2

[0035] An electroluminescent thin film and a preparation method thereof, specifically comprising the following steps:

[0036] Step 1: Surface treatment of the substrate:

[0037] The substrate was ultrasonically cleaned with hydrogen peroxide, ultrapure water, acetone, and ethanol for 5 minutes, and then dried to obtain the cleaned substrate;

[0038] Step 2: Perform magnetron sputtering on the single-sided layer of the substrate obtained in step 1 to plate a conductive film layer:

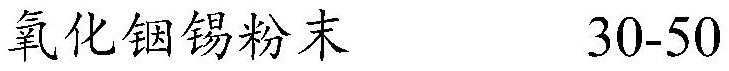

[0039] Production of target materials: After uniform particle size indium tin oxide powder, nickel oxide powder, tungsten oxide powder, and lithium oxide powder are uniformly mixed by wet method, the mass ratio of indium tin oxide powder, nickel oxide powder, tungsten oxide powder, and lithium oxide powder The temperature is 35:25:20:10, and the prefabricated composite powder is prepared by raising the temperature. The prefabricated composite powder is granulated and screened, and then the compo...

Embodiment 3

[0044] The difference between this embodiment and embodiment 2 is:

[0045] In step 2: the mass ratio of indium tin oxide powder, nickel oxide powder, tungsten oxide powder, lithium oxide powder is 40:22:20:8; Press sintering; the sintering temperature is 1100°C, and the sintering time is 3h.

[0046] In step 3: the mass ratio of its acrylic liquid crystal resin monomer, acrylate monomer, vinyl ether monomer, ethylene glycol phenyl ether monomer, photoinitiator, promotor, liquid crystal monomer and spacer is 30: 25:10:7:0.8:0.3:26:0.9;

[0047] Step 4: the applied voltage of the electric field is 80V, the frequency of the applied voltage is 600Hz, the intensity of ultraviolet light is 60mw / cm2, and the irradiation time of ultraviolet light is 1200s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com