Engine cooling liquid complex agent and preparation method thereof

A technology of engine coolant and compounding agent, which is applied in the field of engine coolant, can solve problems such as difficult management, cumbersome and inconvenient production, poor corrosion inhibition performance of engine coolant, etc., and achieve simplified production operations, good stability and compatibility, The effect of good stability and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

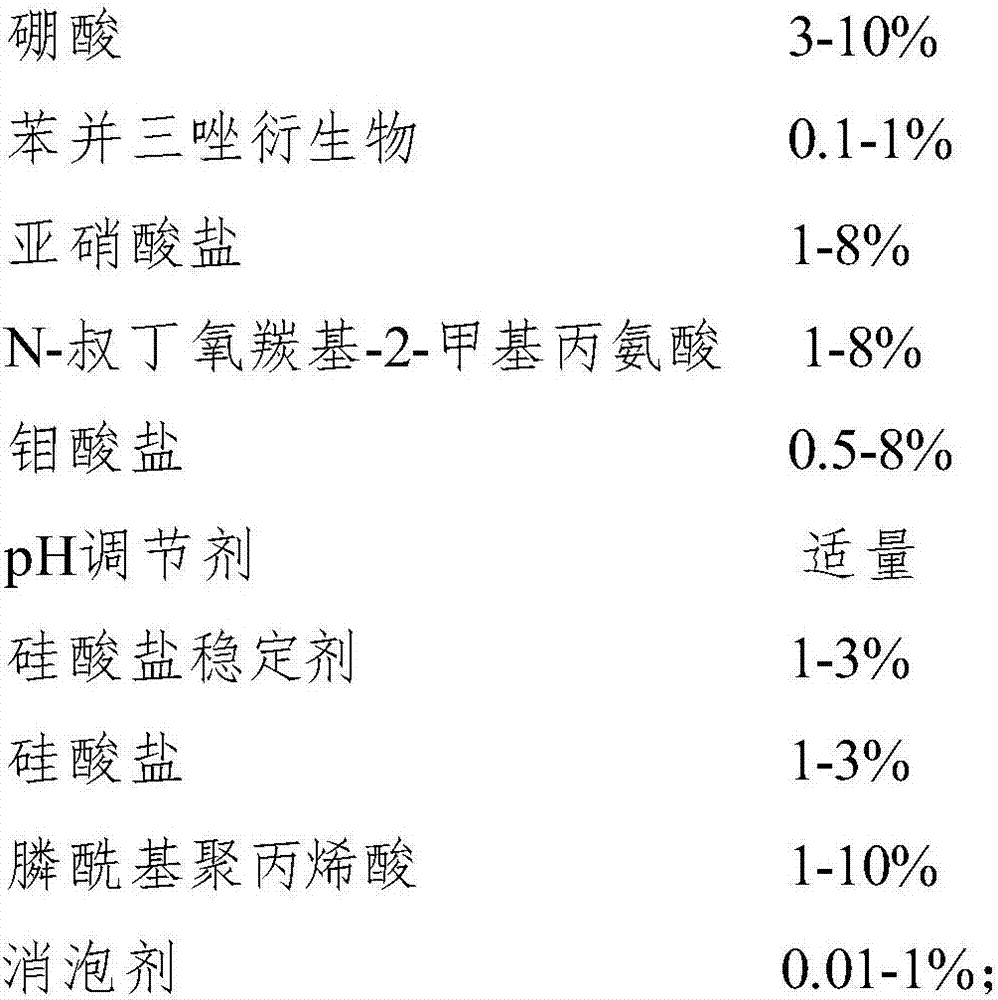

Embodiment 1

[0043] A kind of engine coolant composite agent, is made up of base liquid and additive, wherein, base liquid is the mixture of octyldodecanol and water that weight ratio is 1:4, and described additive is made up of the following components by weight percentage of base liquid :

[0044]

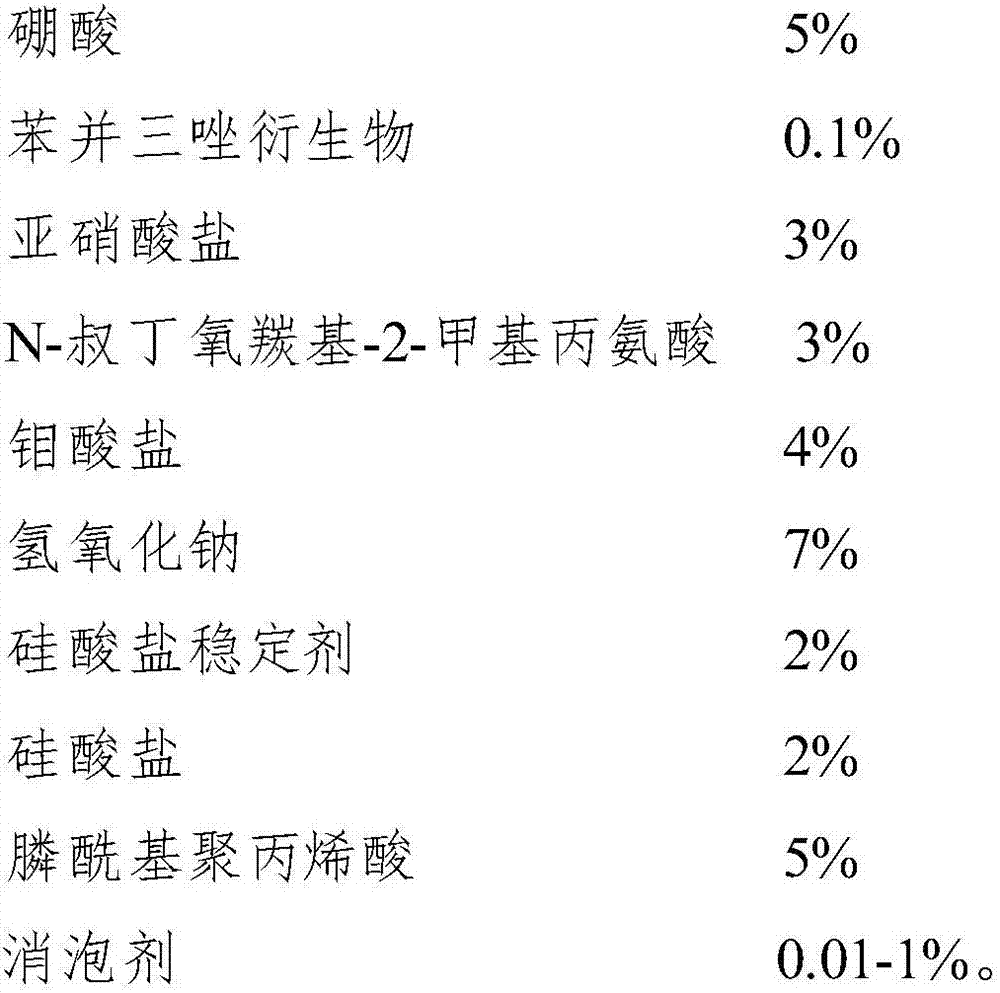

Embodiment 2

[0046] A kind of engine coolant composite agent, is made up of base liquid and additive, wherein, base liquid is the mixture of octyldodecanol and water that weight ratio is 1:4, and described additive is made up of the following components by weight percentage of base liquid :

[0047]

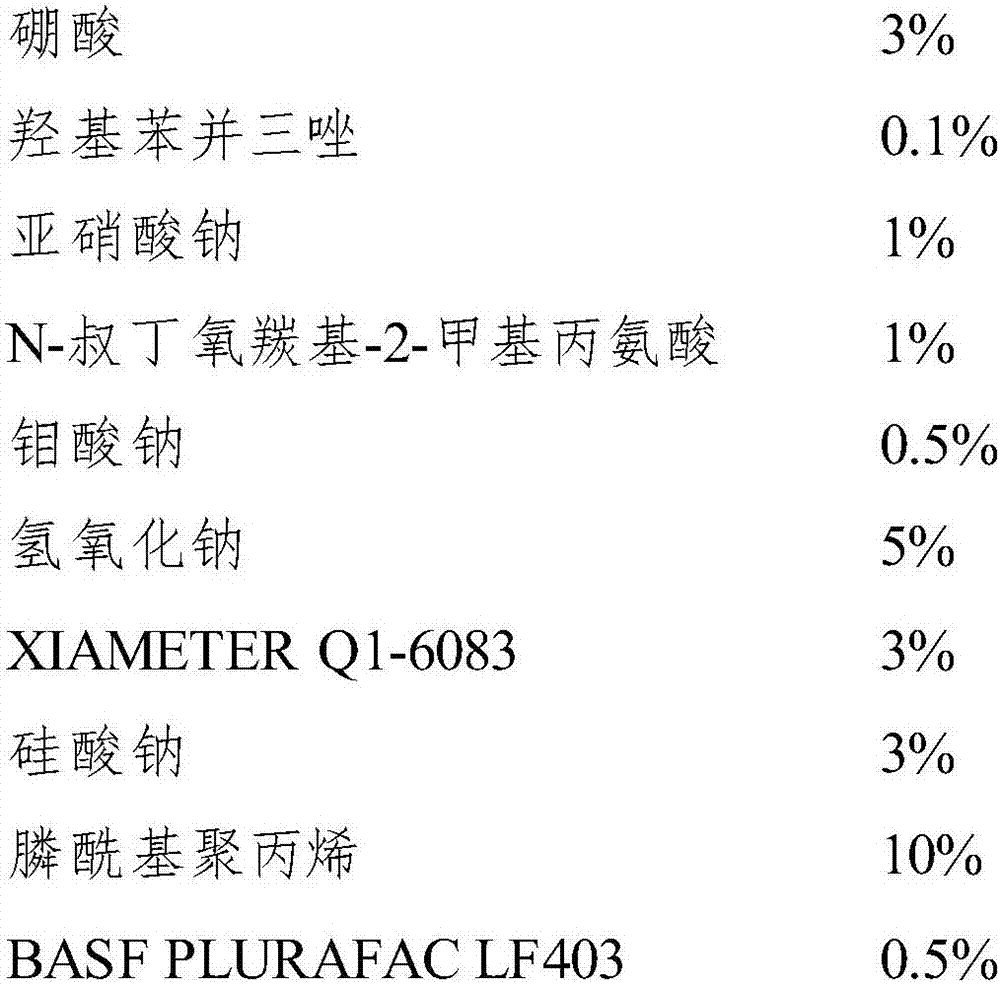

Embodiment 3

[0049] A kind of engine coolant composite agent, is made up of base liquid and additive, wherein, base liquid is the mixture of octyldodecanol and water that weight ratio is 1:4, and described additive is made up of the following components by weight percentage of base liquid :

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com