Lotus seed core drilling machine

A technology for drilling cores and lotus seeds, which is applied in the field of lotus seed processing equipment, can solve the problems of not being able to meet mass production, slow manual processing speed, and high labor intensity, and achieve good market prospects, save labor, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

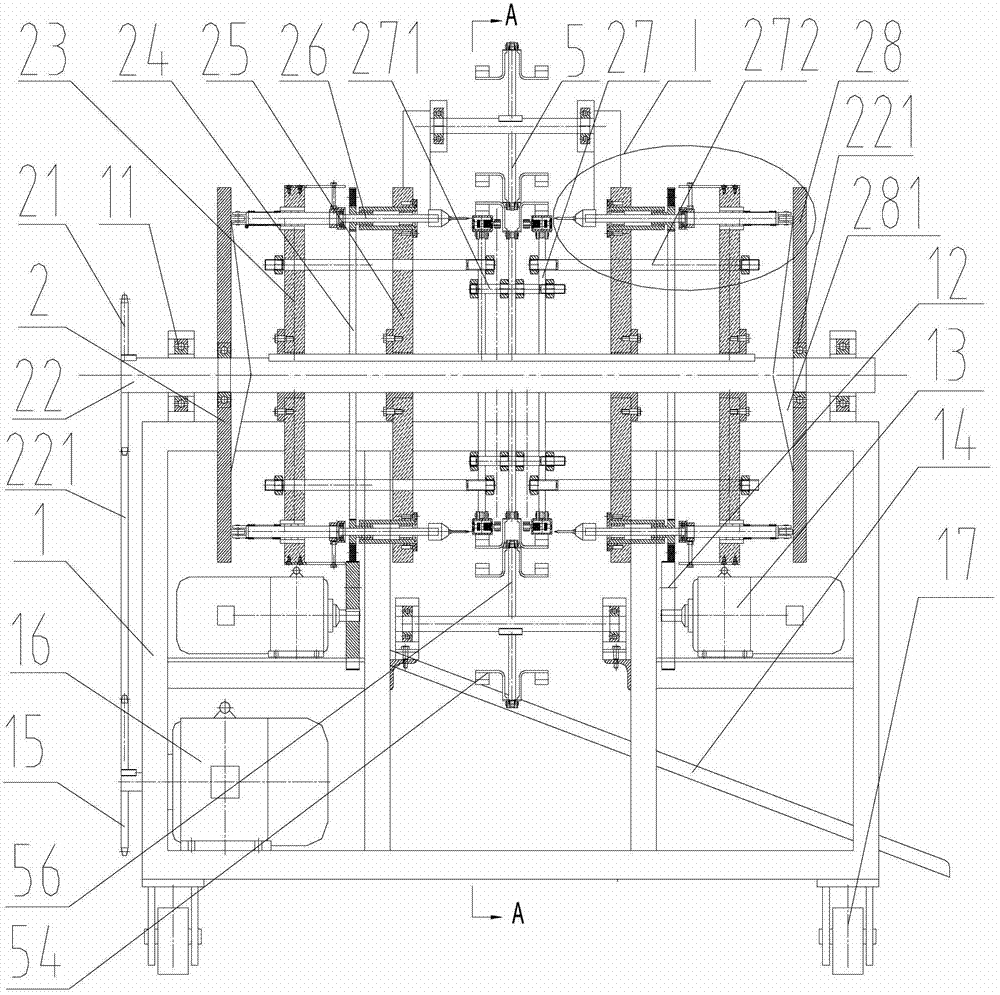

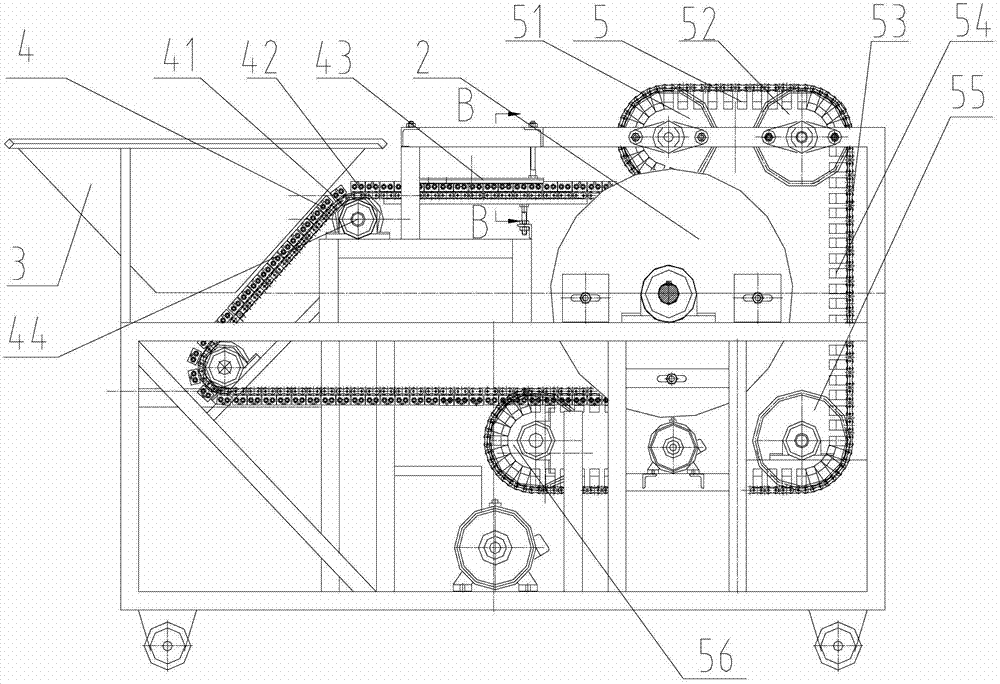

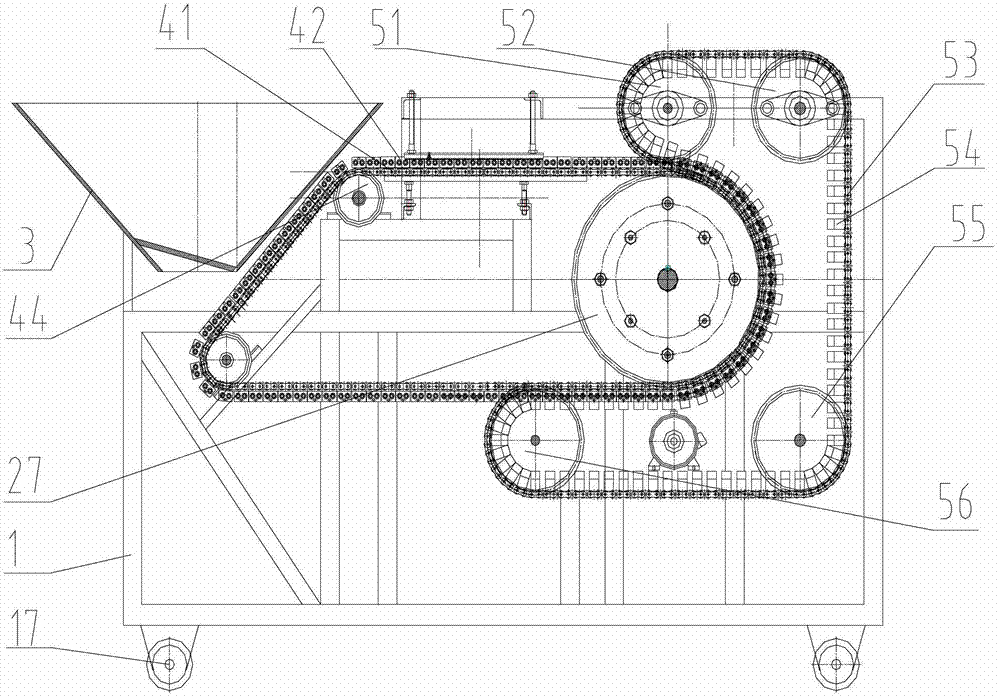

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] Such as Figure 1~3 As shown, the present invention includes a frame 1, a hopper 3, an adjustment feeding device 4, a coring device 2 and a discharge conveying device 5, and the bottom of the frame 1 is provided with four universal wheels 17. Described coring device 2 comprises main shaft 22, and main shaft 22 is installed on the frame 1 by two bearings 11, and main shaft 22 is provided with sprocket wheel 21, two main boards 23, two gears 24, two guide plates 25 and Two conveyor sprockets 27; the sprocket 21 is positioned at one end of the main shaft 22, and is connected with the drive sprocket 15 on the output shaft of the first motor 16 by the first chain 221; the mainboard 23, gear 24, guide plate 25 and The conveying sprocket 27 is fixedly connected as a whole by studs 271, 272; the conveying sprocket 27 is provided with a chain 41 for adjusting the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com