Parallel multi-angle tilted fiber bragg grating and preparation method thereof

A fiber Bragg, multi-angle technology, applied in cladding optical fiber, optical waveguide light guide, light guide, etc., can solve the problems of large limitations, and achieve the effect of being suitable for batch processing, accurate angle, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

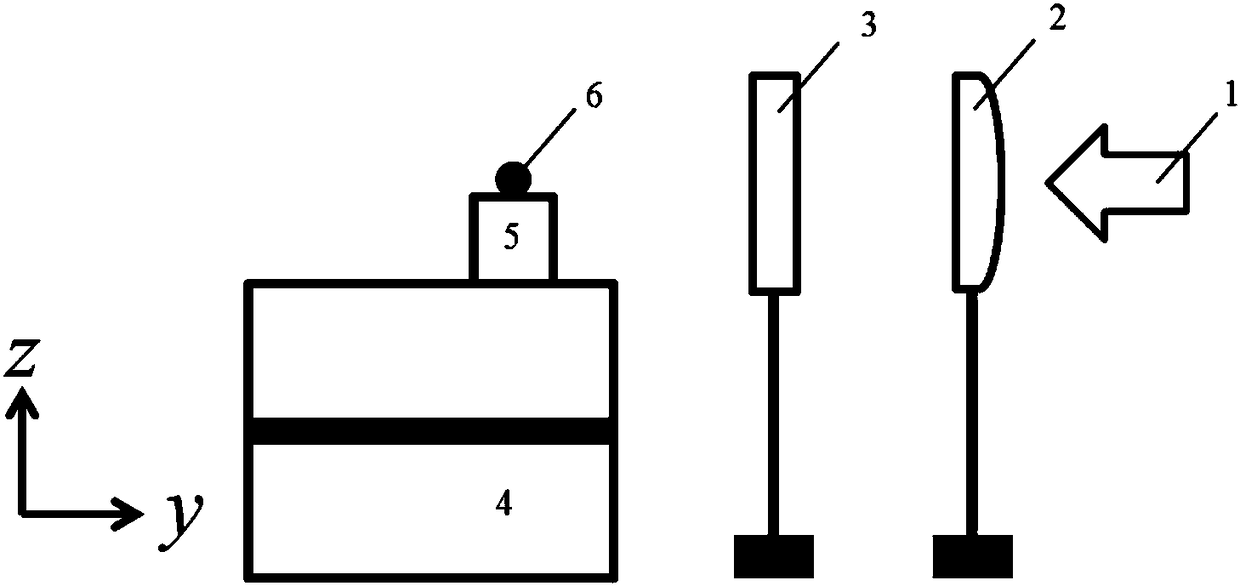

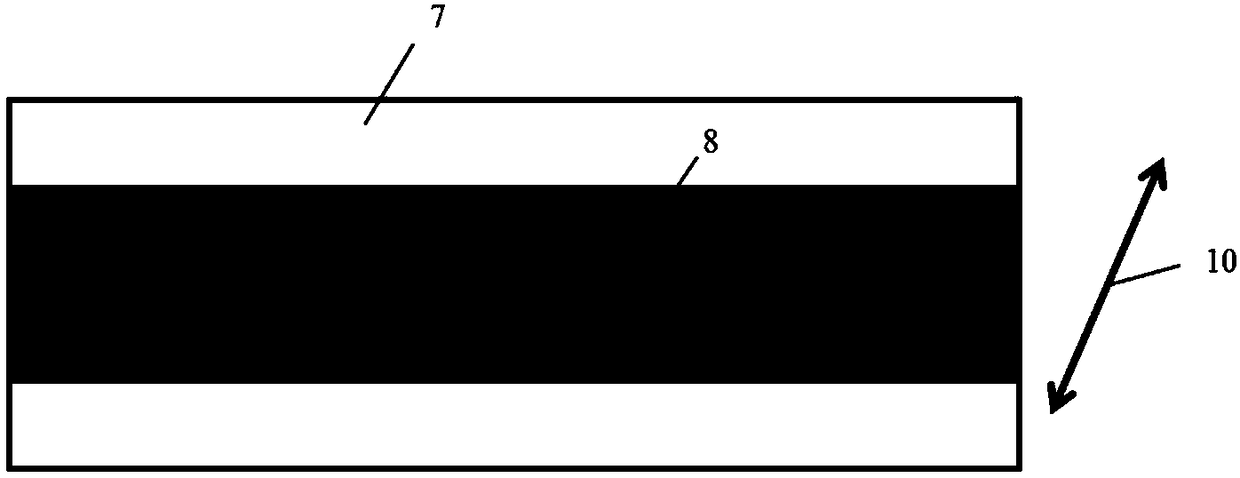

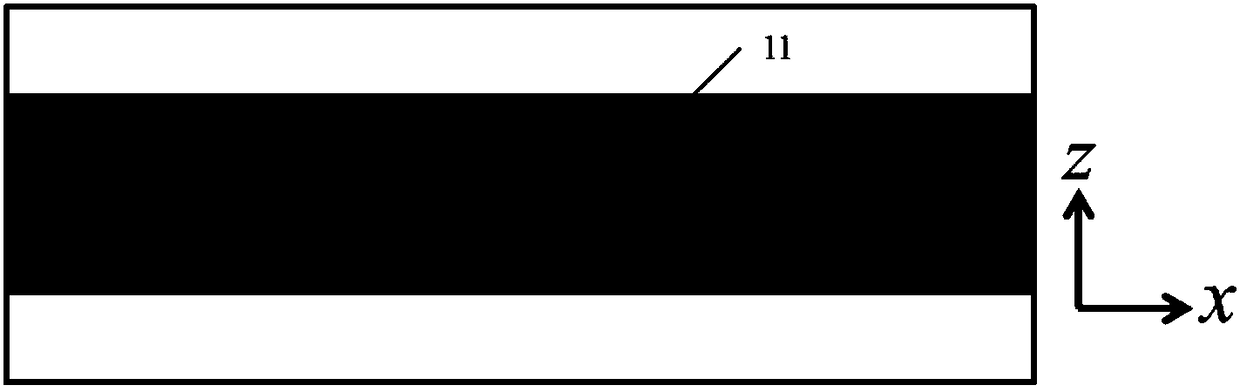

[0048] like figure 1 As shown, this embodiment takes the processing of 2°+8° double-angle tilted fiber Bragg grating as an example, the details are as follows:

[0049] Raw materials: Corning SMF-28 single-mode optical fiber with a cladding diameter of 125 μm and a core diameter of 9 μm.

[0050] The preparation steps and detailed implementation of the 2°+8° dual-angle tilted fiber Bragg grating are specifically described as follows:

[0051] (1) Remove about 2 cm of the coating layer from the middle part of the optical fiber 6, and clean it with a dust-free paper stained with alcohol;

[0052] (2) Fix the optical fiber 6 on the optical fiber holder 5 , wherein the part where the coating layer is stripped faces the phase mask 3 . The laser is focused on the upper half inside the fiber core by adjusting the three-dimensional moving platform 4 . The pulse width of femtosecond laser 1 is 100fs, and the power is set to 600mW. According to the desired processing angle 2°, the s...

Embodiment 2

[0056] In this embodiment, the processing of 6°+11°+15° three-angle inclined fiber Bragg grating is taken as an example, the details are as follows:

[0057] Raw materials: Corning SMF-28 single-mode optical fiber with a cladding diameter of 125 μm and a core diameter of 9 μm.

[0058] The preparation steps and detailed implementation of the 6°+11°+15° three-angle tilted fiber Bragg grating are specifically described as follows:

[0059] (1) Remove about 2 cm of the coating layer from the middle part of the optical fiber 6, and clean it with a dust-free paper stained with alcohol;

[0060] (2) Fix the optical fiber 6 on the optical fiber holder 5 , wherein the part where the coating layer is stripped faces the phase mask 3 . The laser is focused on the upper third of the fiber core by adjusting the three-dimensional moving platform 4 . The pulse width of femtosecond laser 1 is 100fs, and the power is set to 600mW. According to the desired processing angle of 6°, the scannin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com