Lotus seed core drilling machine

A technology of core drilling and lotus seeds, which is applied in the field of lotus seed processing equipment, can solve the problems of not being able to meet mass production, slow manual processing speed, and high labor intensity of workers, and achieve good market prospects, labor saving, and low manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

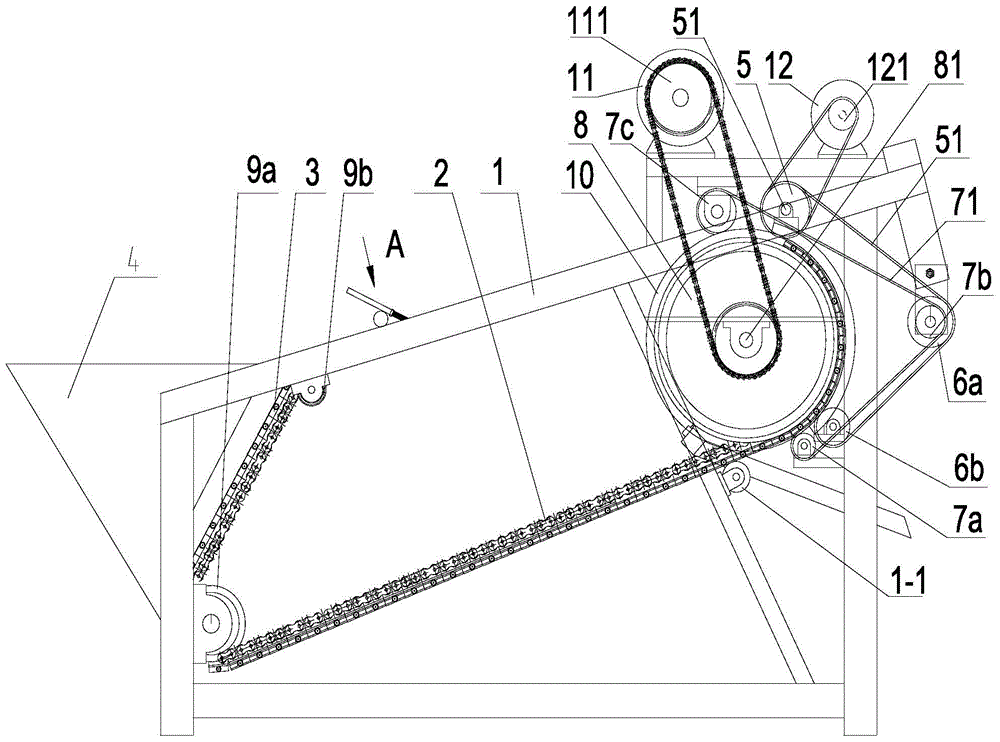

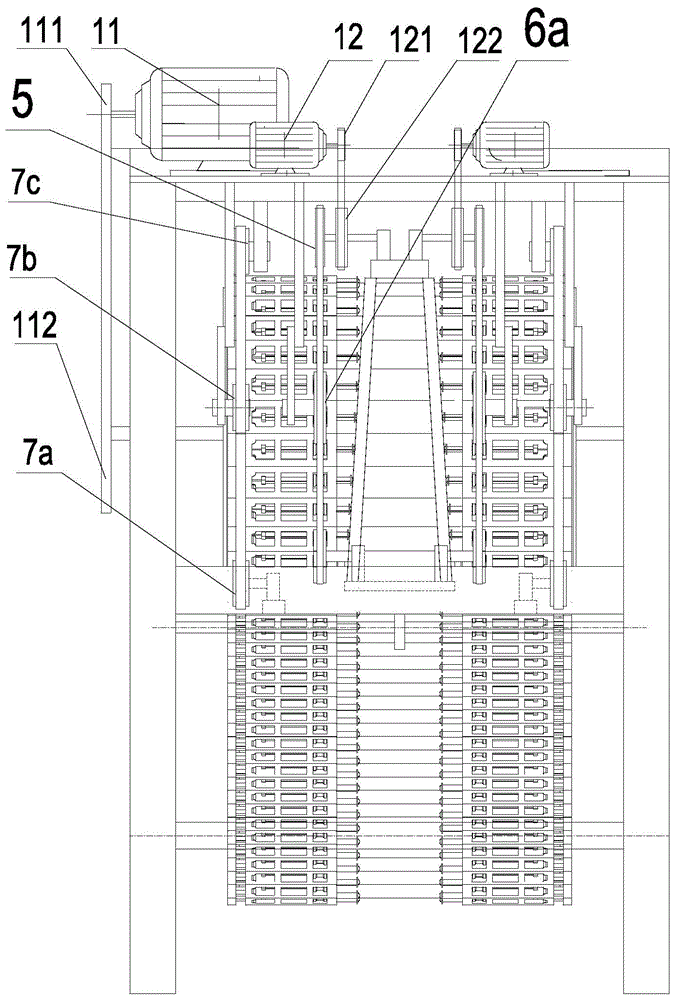

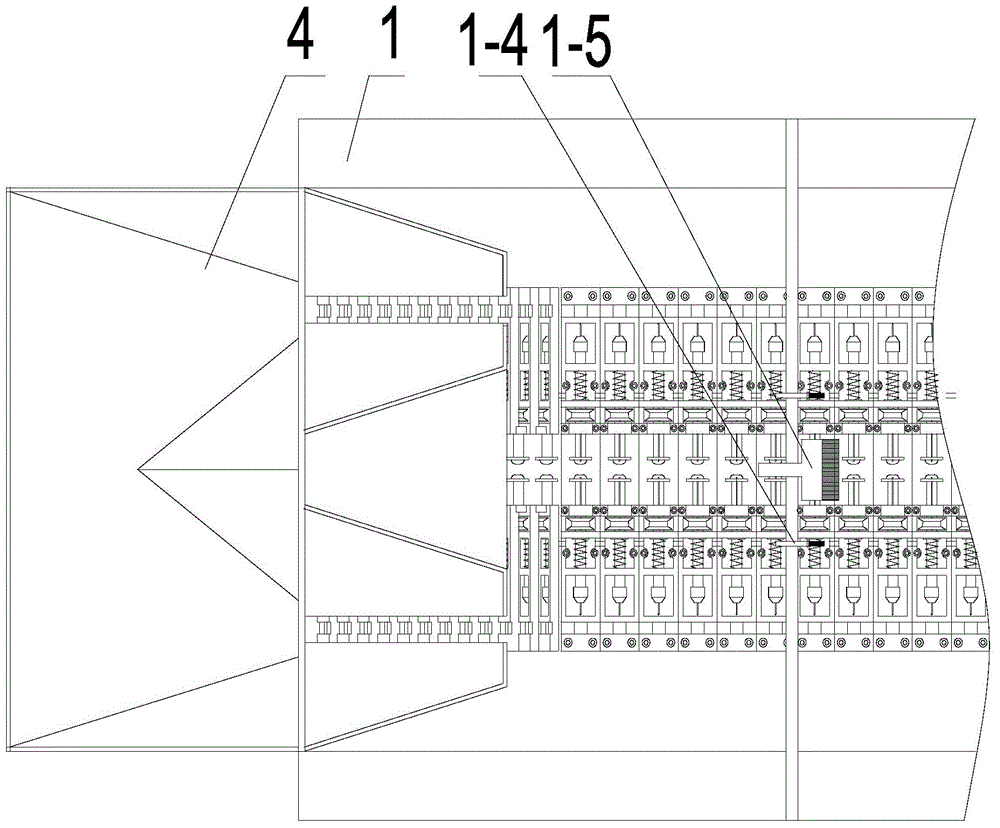

[0032] Such as Figure 1~5 As shown, the present invention comprises a frame 1, a hopper 4, a plurality of coring devices 3, a driving pulley 5, two driven pulleys 6a, 6b, a transmission belt 51, a pressing belt 71, and three pressing pulleys 7a , 7b, 7c, feeding tray 10, driving sprocket 8, two driven sprockets 9a, 9b and conveyor chain 2.

[0033] Such as Figure 6-Figure 9 As shown, the core removal device 3 includes a base 31, a drill rod 32, a drill bit 34 and a pulley 33; the base 31 is provided with an alignment hole 311 and a spring mounting hole 314 for only accommodating a lotus seed. And the pulley hole 315, the self-aligning hole 311 is rectangular (also can be drum-shaped). The base 31 is provided with a drill pipe hole, and the drill pipe 32 is inserted into the drill pipe hole. The drill rod 32 is provided with a keyway 321, the drill rod 32 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com