LED light-embedding artistic glass and method of manufacturing the same

A technology of art glass and manufacturing methods, applied in decorative arts, chemical instruments and methods, glass/slag layered products, etc., can solve the problems of easy falling off of LEDs, affecting conductive functions, and fragile glass, and achieve strong market potential, Good light transmission performance and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

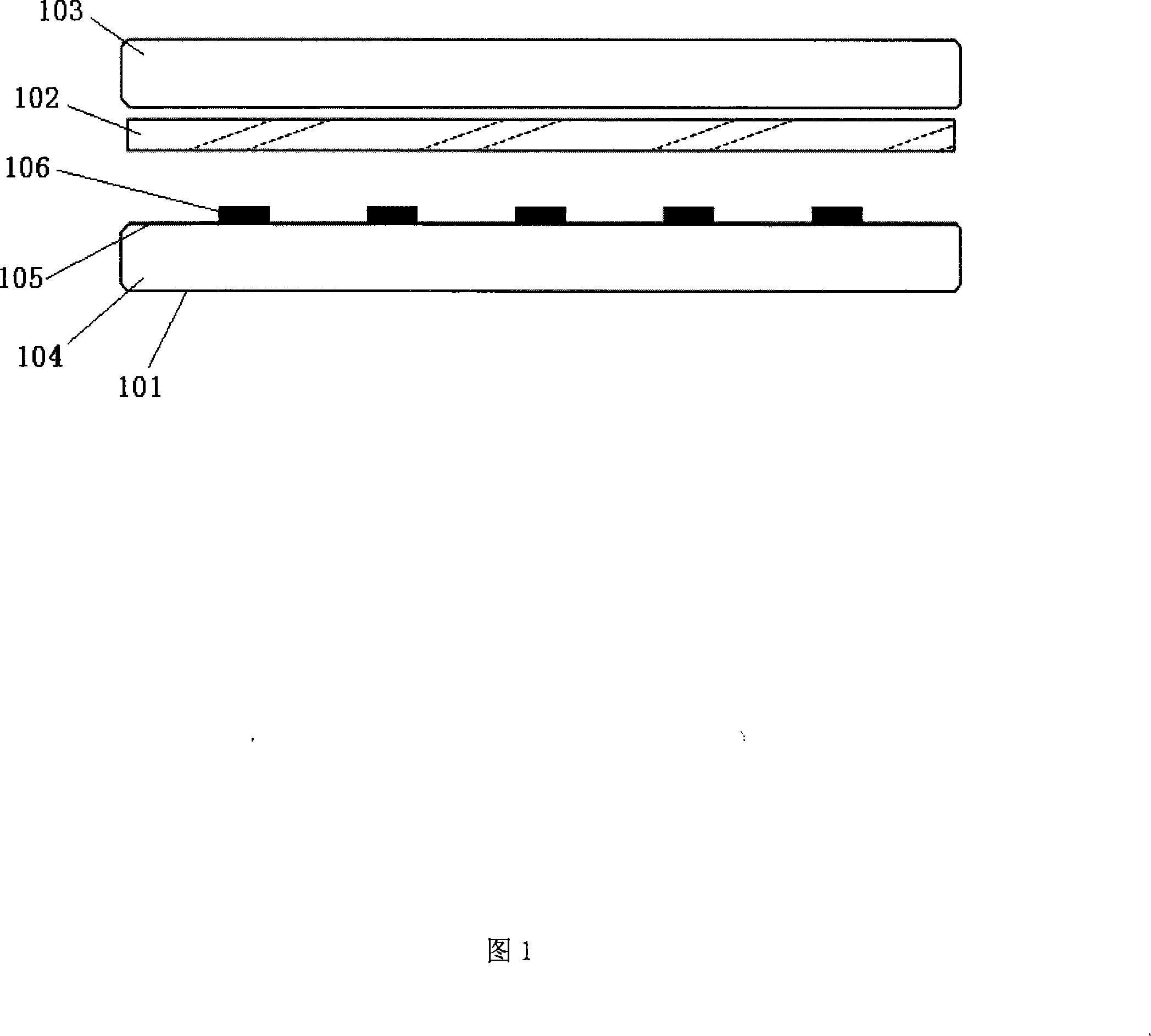

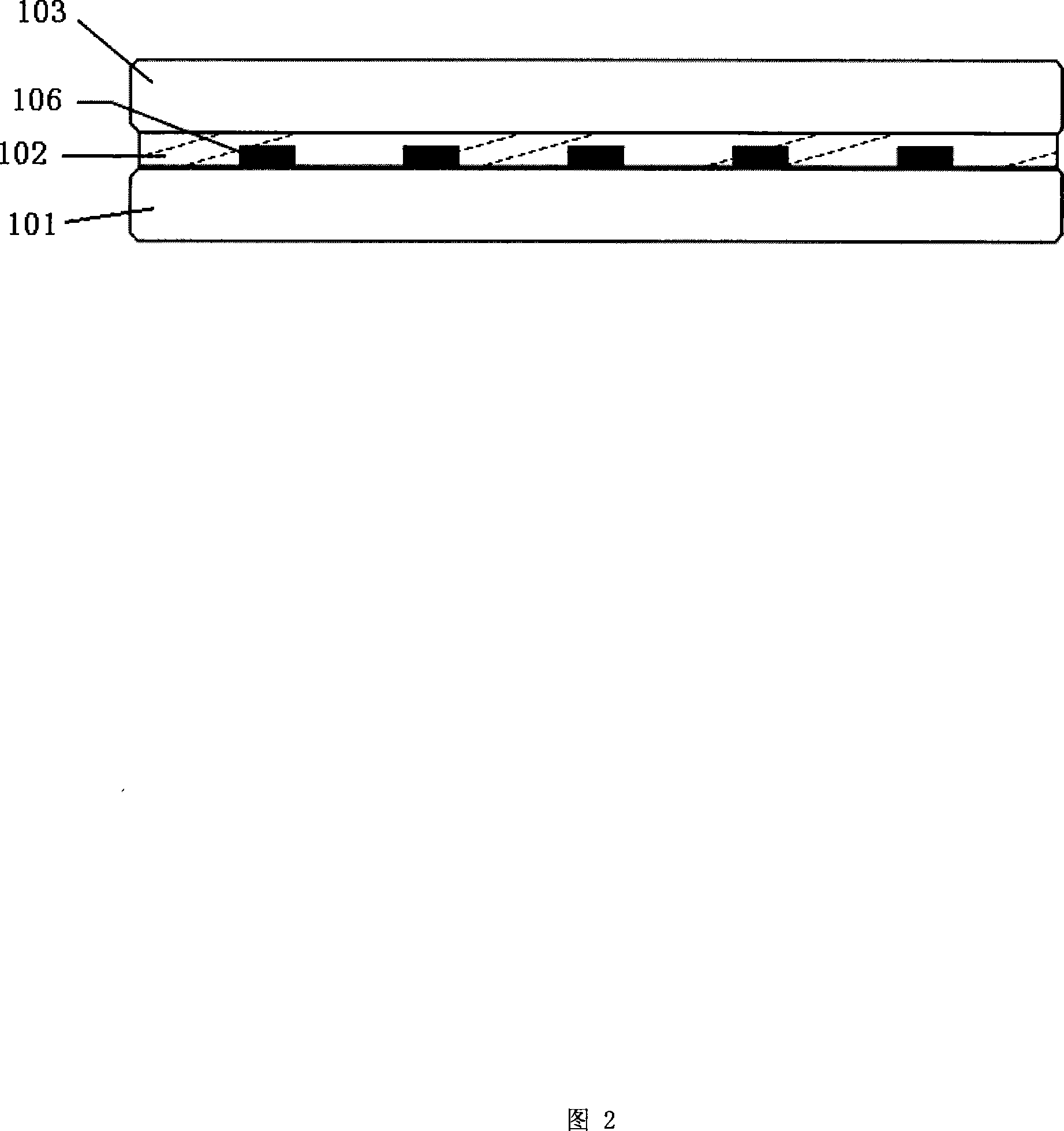

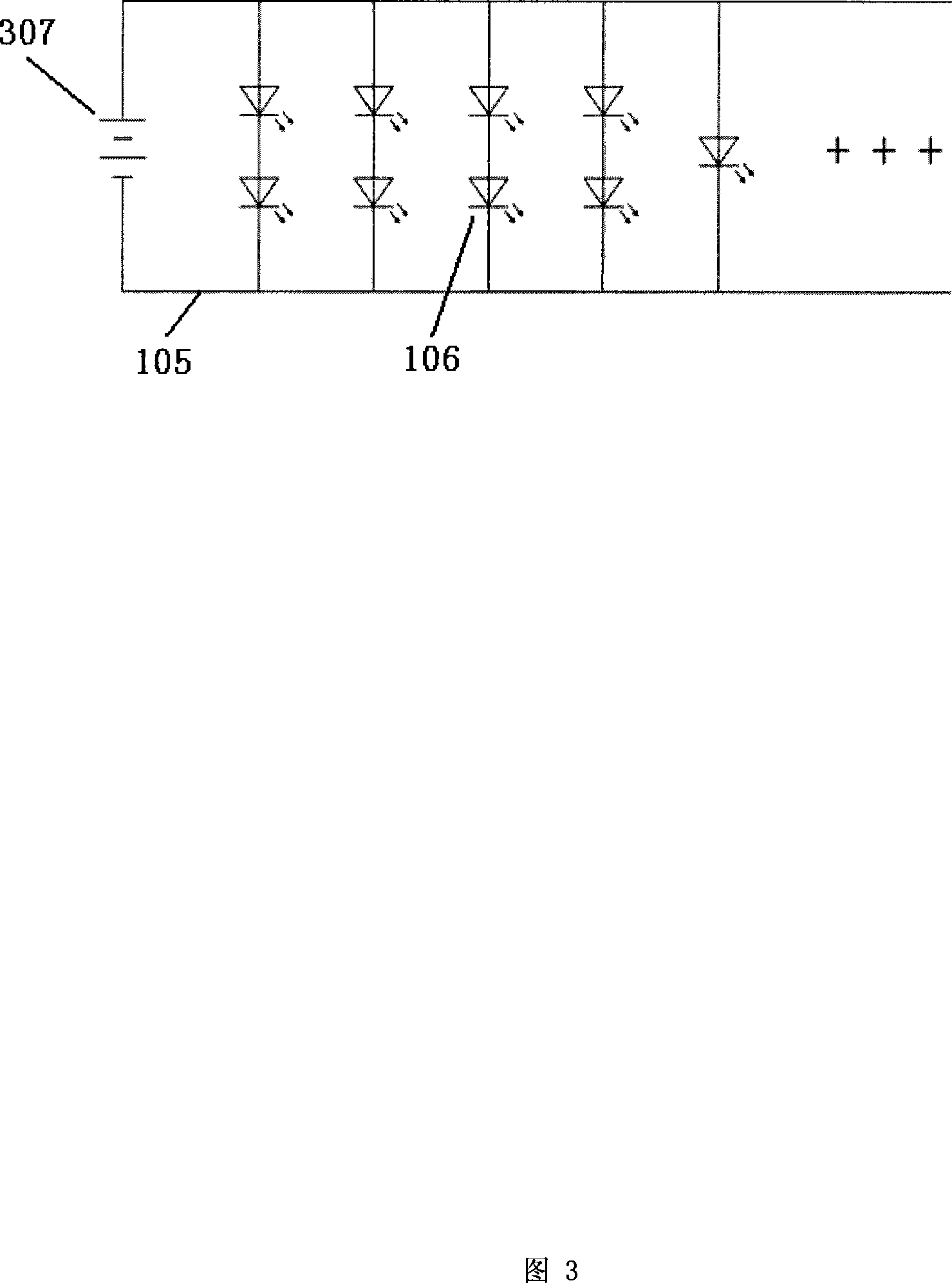

[0032] As shown in Figure 1: the bottom layer of the base layer 101 is conductive glass 104, the conductive glass 104 is made of soda-calcium-based or silicon-boron-based substrate glass, and its surface has a layer of indium tin oxide (commonly known as ITO) plated by magnetron sputtering technology. )membrane. On the indium tin oxide film, there is a conductive circuit 105 manufactured by etching or photolithography, and the conductive circuit 105 has a power interface to be connected to an external power supply to supply power to the conductive circuit 105 . The conductive glass 104 is cured with a pattern composed of many LED luminous bodies 106. Curable conductive silver paste can be used for curing. Therefore, the LED luminous body 106 is connected with the conductive circuit 105. When the external power supply is connected, the conductive circuit 105 supplies power to the LED illuminant 106 to make it emit light to form the required displayed characters, patterns, color...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com