Welding tool

A technology of welding tooling and tooling frame, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low efficiency, difficult welding, and difficulty in ensuring welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

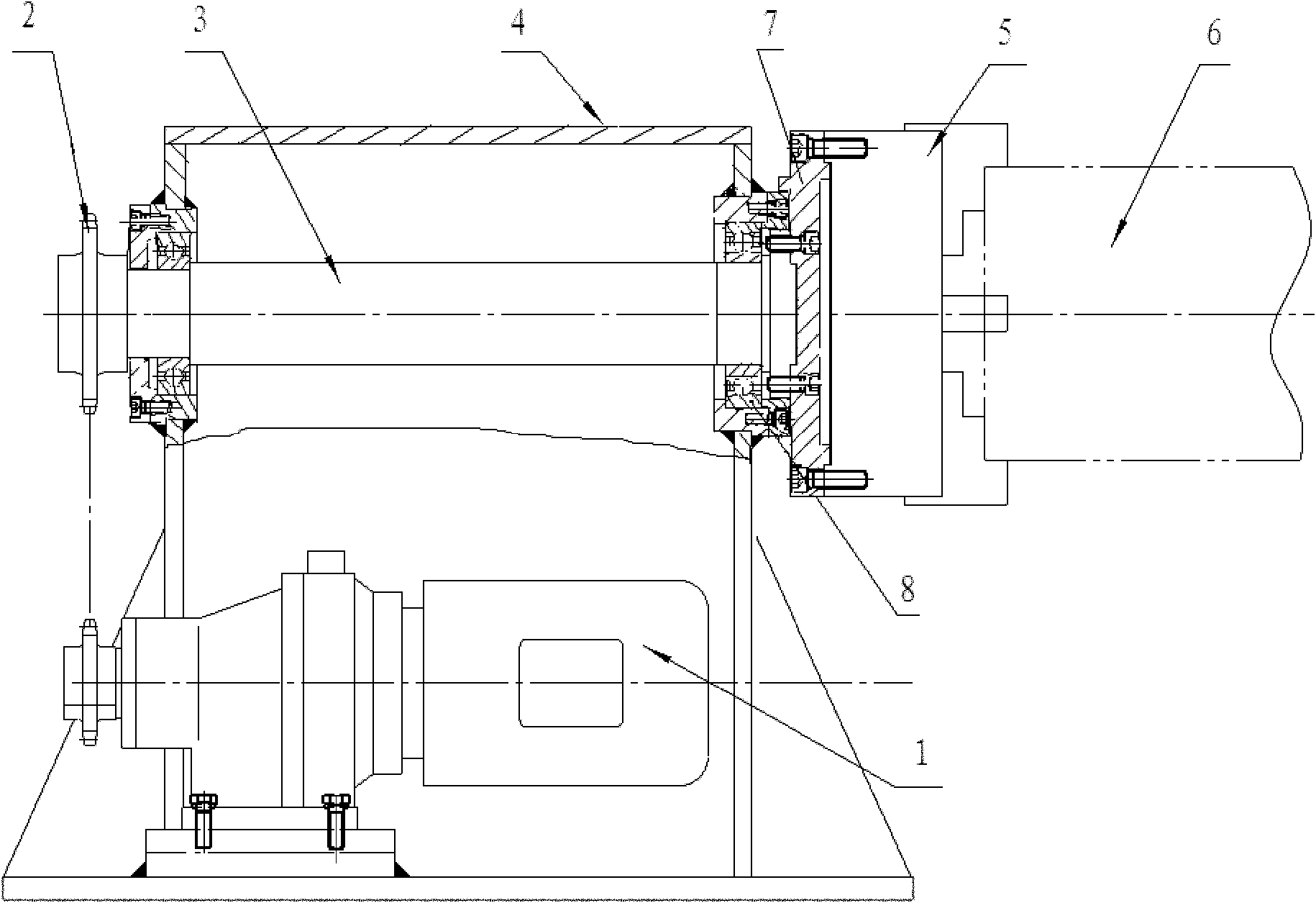

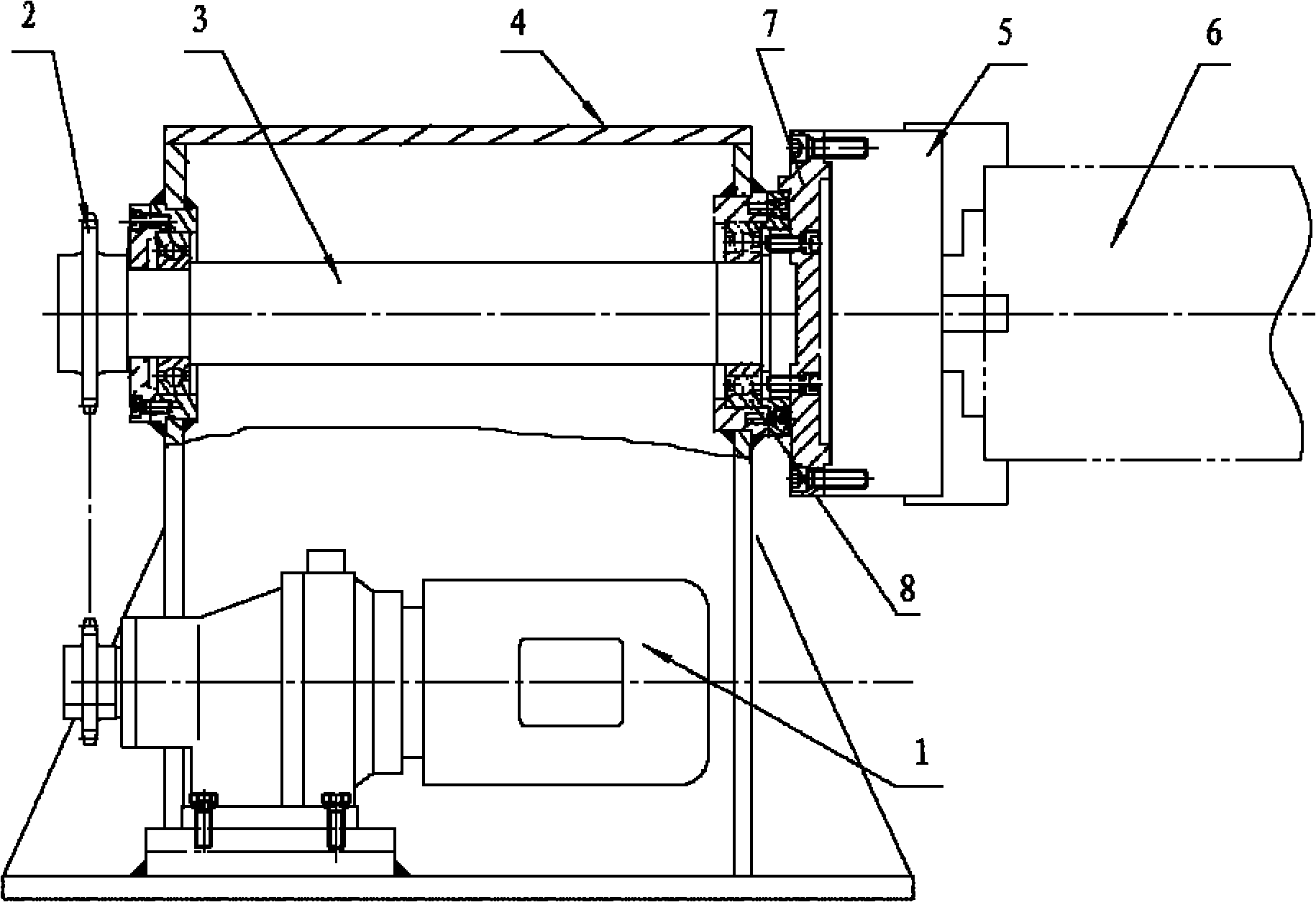

[0005] The speed regulating motor 1 drives the transmission shaft 3 installed on the welding tool frame 4 through the transmission of the sprocket 2, the transmission shaft 3 is supported by a pair of radial bearings 8, and the transmission shaft 3 is connected with the three-jaw chuck 5 through the flange 7 , the welding workpiece 6 is installed on the three-jaw chuck 5, and the welding can be carried out by starting the motor to rotate the workpiece. By controlling the rotational speed of the speed-regulating motor 1, ideal welding needs can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com