Pretreatment method for improving direct spray inkjet printing definition of polyester fabric

A polyester fabric, inkjet printing technology, applied in fiber treatment, dyeing, textiles and papermaking, etc., can solve the problems of high cost, affecting the feel of printed fabrics, not suitable for batch processing of polyester fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment selects 230g / m for use 2 Polyester warp knitted fabric, the process used is as follows:

[0027] (1) Preparation of porous nano-silica dispersion: Take 12g of glycidyltrimethylammonium chloride, 0.4g of Tween 60, 147.6g of deionized water, after fully stirring under the mixer, add 40g of porous nano-silica Silicon, continue to stir for 30 minutes, and then place it in a laboratory circulating sand mill to grind for 2 hours to obtain a porous nano-silicon oxide dispersion with an average particle size of <200nm and a porous nano-silicon oxide content of 20%;

[0028] (2) Preparation of pretreatment liquid: 60g of porous nano-silica dispersion, 4g of antistatic agent TM, 4g of urethane thickener, 6g of Tween 60, 126g of deionized water, fully stirred under the stirrer, the speed 800-1000r / min, the stirring time is 30min, and the fabric pretreatment liquid is obtained.

[0029] (3) padding pretreatment liquid: the polyester fabric padding pretreatment liq...

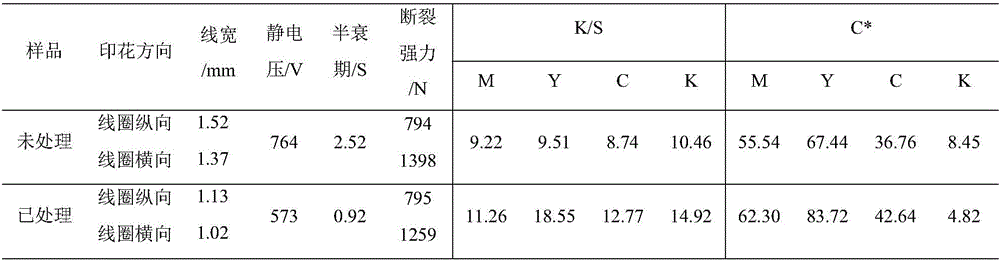

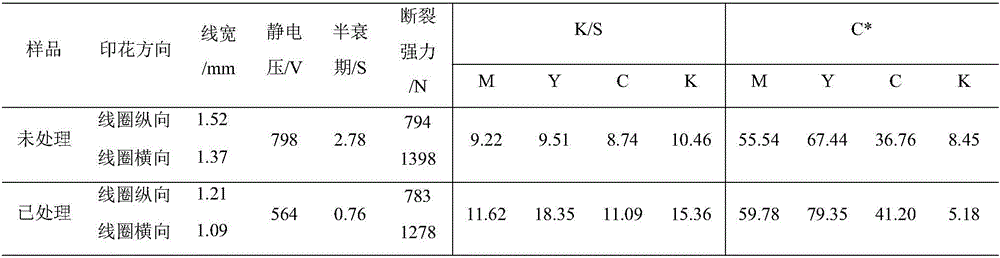

Embodiment 2

[0037] This embodiment selects 230g / m for use 2 Polyester warp knitted fabric, the process used is as follows:

[0038] (1) Preparation of porous nano-titanium oxide dispersion: take 10g of glycidyltrimethylammonium chloride, 0.8g of Tween 60, 149.2g of deionized water, after fully stirring under the stirrer, add 40g of porous nano-titanium oxide Titanium, continue to stir for 30 minutes, and then place it in a laboratory circulating sand mill and grind for 2 hours to obtain a porous nano-titanium oxide dispersion with an average particle size of <200nm and a porous nano-titanium oxide content of 20%;

[0039] (2) Preparation of pretreatment liquid: with 80g of porous nano-titanium oxide dispersion, 4g of antistatic agent TM, 6g of urethane thickener, 6g of Tween 60, 104g of deionized water, fully stirred under the stirrer, the rotating speed 800-1000r / min, the stirring time is 30min, to obtain the fabric pretreatment liquid;

[0040](3) padding pretreatment liquid: the poly...

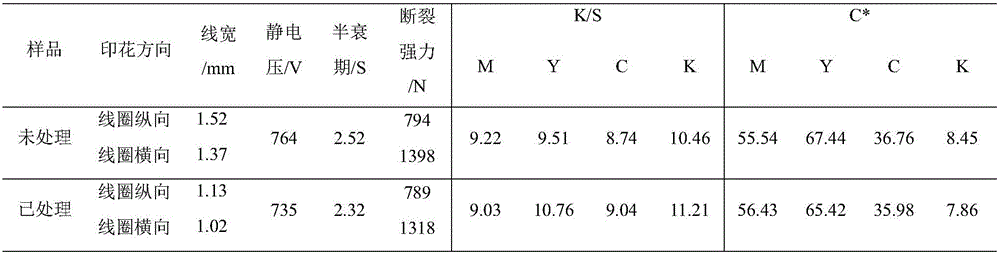

Embodiment 3

[0048] This embodiment selects 230g / m 2 Polyester warp knitted fabric, the process used is as follows:

[0049] (2) Preparation of pretreatment solution: 4g of antistatic agent TM, 4g of urethane thickener, 6g of Tween 60, 186g of deionized water, fully stirred under the agitator, rotating speed 800-1000r / min, stirring time 30min to obtain the fabric pretreatment solution.

[0050] (3) padding pretreatment liquid: the polyester fabric padding pretreatment liquid, during padding, the liquid rate is controlled between 60-100%;

[0051] (4) Pre-baking and baking: pre-baking the padded fabric at 60°C, and then baking at 150°C;

[0052] (5) Inkjet printing: Under the condition of 720×540dpi, 3Pass, water-based disperse dye ink is used for inkjet printing;

[0053] (6) Sublimation and color fixation: Sublimation and color fixation at 180° C. for 1 min.

[0054] Table 3 Performance changes before and after fabric treatment

[0055]

[0056] As can be seen from Table 3, compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com