Man-made diamond grinding paste

A technology of artificial diamond powder and diamond, which is applied in the field of abrasive paste, can solve problems such as damage and precision mold scratches, and achieve the effects of reducing costs, improving production efficiency, and high surface quality and surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of artificial diamond abrasive paste, is made up of artificial diamond powder, mixed fat, oleic acid and lubricant, and the parts by weight of its each component are: artificial diamond powder 54 parts, mixed fat 25 parts, oleic acid 21 parts, 3 parts of kerosene; The preparation method of described artificial diamond grinding paste comprises the following steps:

[0018] (1) Accurately weigh each component according to the above parts by weight;

[0019] (2) Mix the components evenly at a temperature of 65°C;

[0020] (3) Cool to 0°C to obtain the diamond grinding paste.

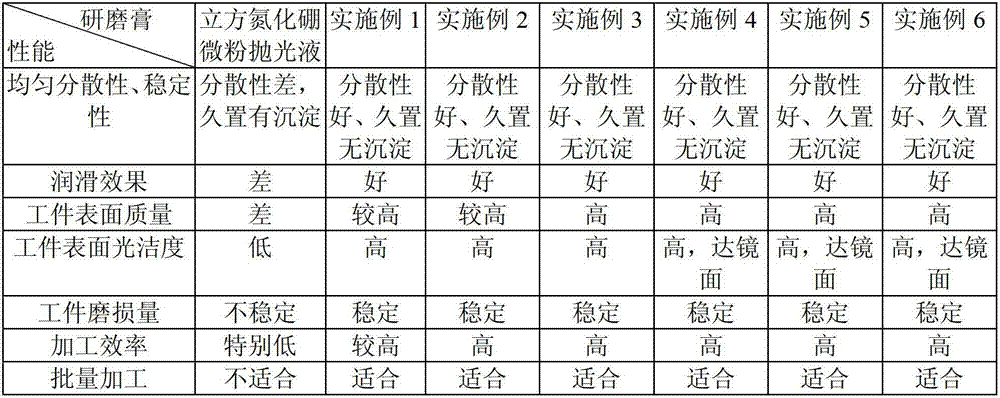

[0021] The diamond abrasive paste that present embodiment is made, its performance index is as shown in table 1, is equivalent to the particle size of our traditional 800# oil stone, but no matter from use or from processing requirement, its precision is higher, and work efficiency is also higher. Improve more than 2-3 times.

Embodiment 2

[0023] A kind of artificial diamond grinding paste, is made up of artificial diamond powder, mixed fat, oleic acid and lubricant, and the parts by weight of its each component are: artificial diamond powder 44 parts, mixed fat 30 parts, oleic acid 26 parts, 4 parts of kerosene; The preparation method of described artificial diamond grinding paste comprises the following steps:

[0024] (1) Accurately weigh each component according to the above parts by weight;

[0025] (2) Mix the components evenly at a temperature of 70°C;

[0026] (3) Cool to 0°C to obtain the artificial diamond grinding paste.

[0027] The diamond abrasive paste that present embodiment is made, its performance index is as shown in table 1, is equivalent to the grain size of our traditional 2000# oil stone, but no matter from use or from processing requirement, its precision is higher, and work efficiency is also higher. Improve more than 2-4 times.

Embodiment 3

[0029] A kind of artificial diamond grinding paste, is made up of artificial diamond powder, mixed fat, oleic acid and lubricant, and the parts by weight of its each component are: artificial diamond powder 40 parts, mixed fat 30 parts, oleic acid 30 parts, 5 parts in kerosene; The preparation method of described artificial diamond grinding paste comprises the following steps:

[0030] (1) Accurately weigh each component according to the above parts by weight;

[0031] (2) Mix the components evenly at a temperature of 68°C;

[0032] (3) Cool to 0°C to obtain the artificial diamond grinding paste.

[0033] The diamond abrasive paste that present embodiment is made, its performance index is as shown in table 1, is equivalent to the grain size of our traditional 800# sandpaper, but no matter from use or from processing requirement, its precision is higher, and work efficiency is also higher. Improve more than 2-3 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com