Ball cup inner-outer surface chroming device

A technology of inner and outer surface and ball head seat, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of low processing efficiency, low cathode and anode current efficiency, poor dispersion ability of chrome plating bath, etc., to improve production efficiency and solve product quality. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the claimed protection scope is not limited to the description.

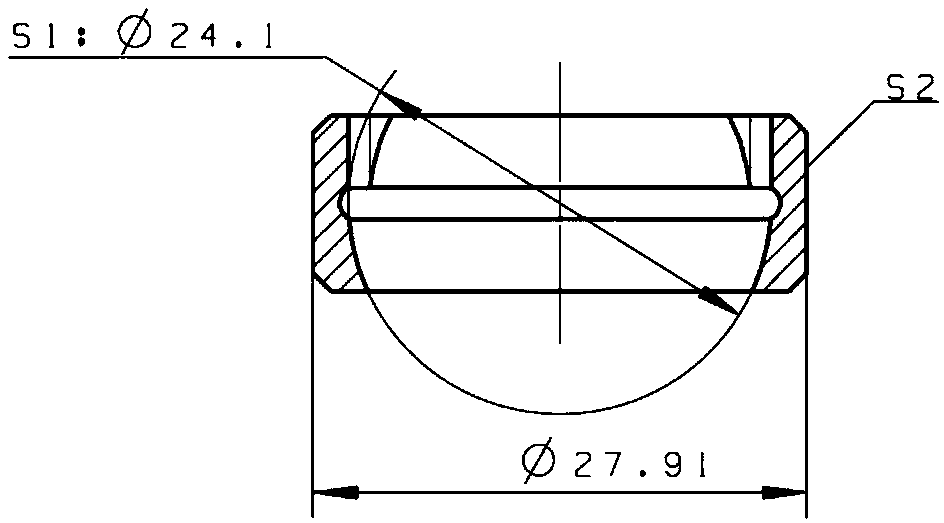

[0030] In the present invention, the inner surface and the outer surface of the ball seat are electroplated separately, so two sets of devices are designed and manufactured, the inner surface chrome-plated component and the outer surface chrome-plated component.

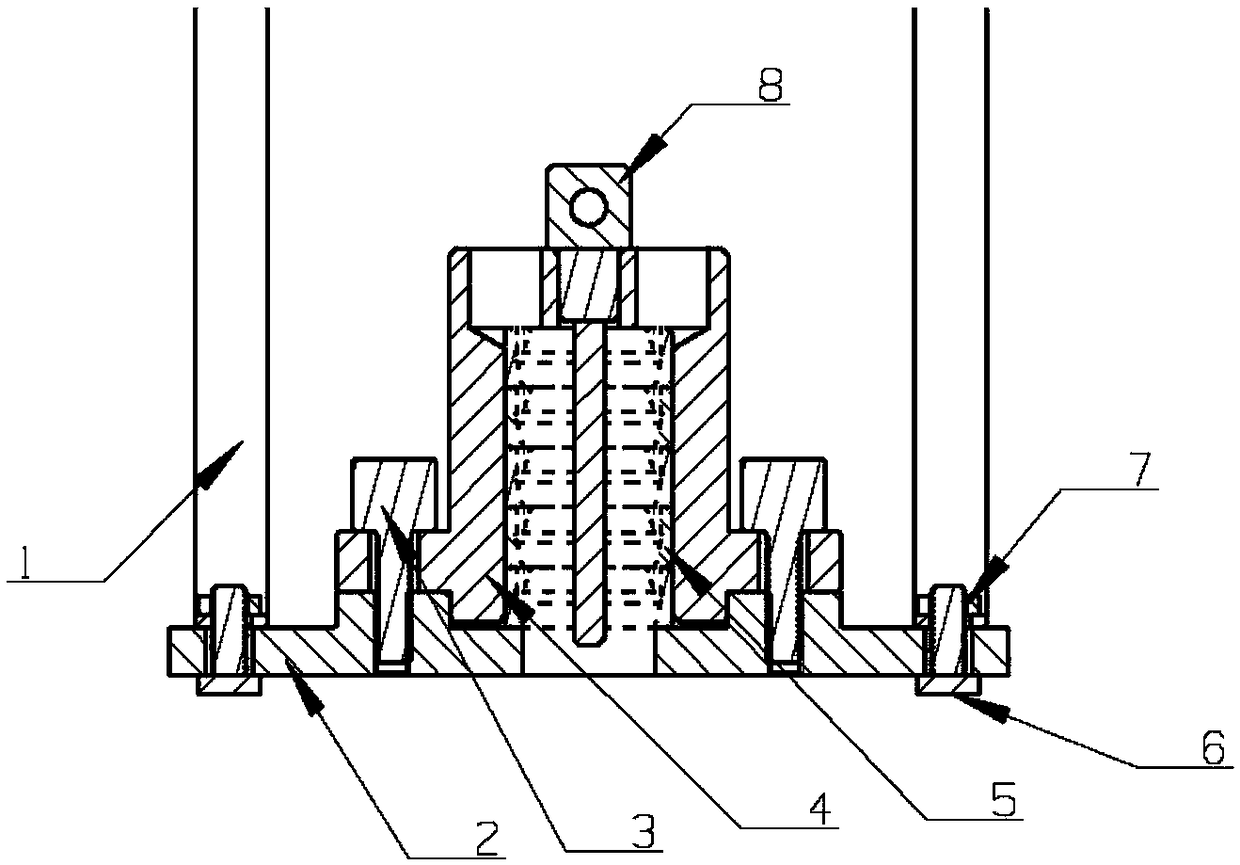

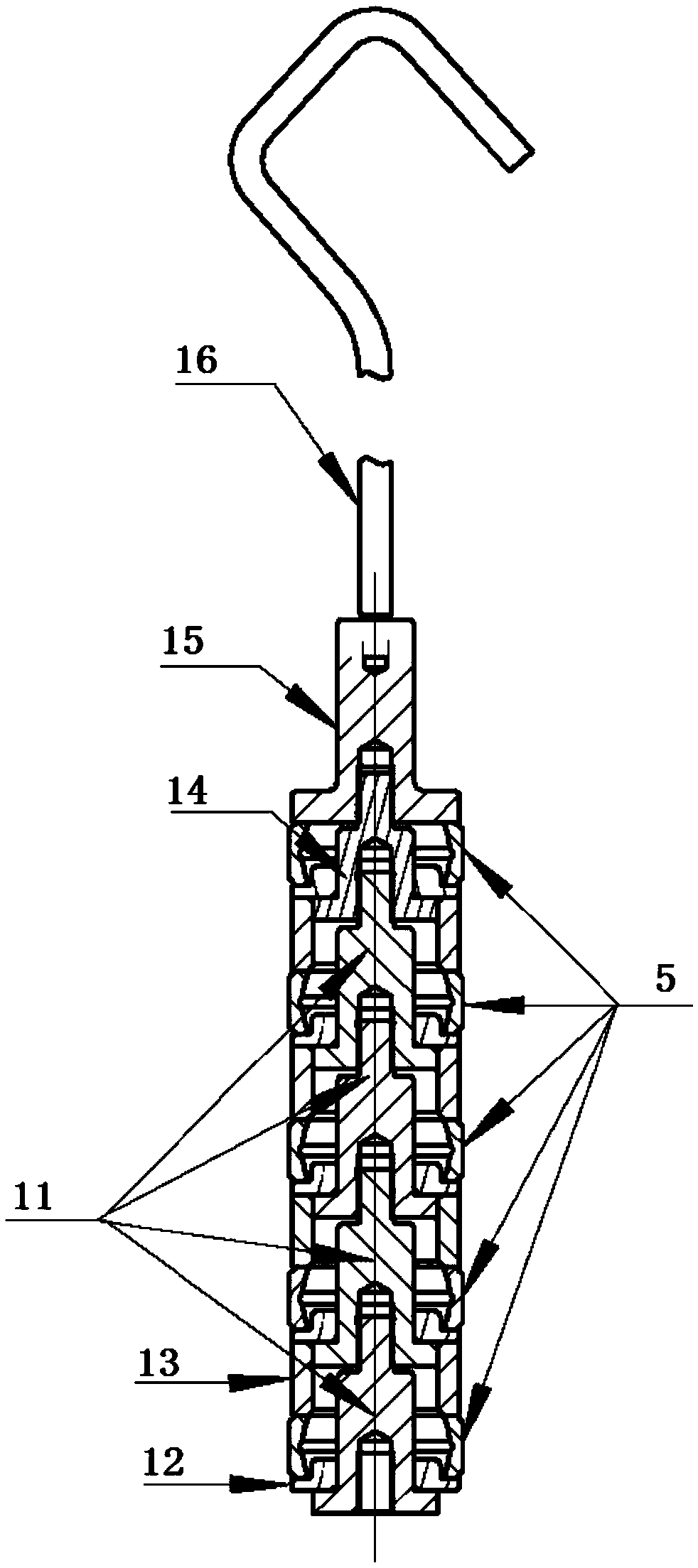

[0031] The chrome-plated component on the inner surface of the part is composed of the first hook 1, the screw 3, the conductive plate 2, the positioning piece 4, the auxiliary anode electrode 8, the nut 7, and the bolt 6 (see figure 2 ).

[0032] The conductive plate 2 should be coaxially installed with the positioning part 4, and the center of the conductive plate 2 has The through hole is conducive to the circulation of the bath, but the diameter is smaller than the outer diameter of the part 5, which is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com