Method for assembling mobile static pressure bearing

A technology of dynamic and static pressure bearings and assembly methods, which is applied in the direction of bearings, shafts, bearings, mechanical equipment, etc., can solve the problems of low precision of dynamic and static pressure bearings, vibration of rotating shafts, and difficult precision of oil tank coaxiality, and achieve shaft vibration The effect of small size, high precision and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

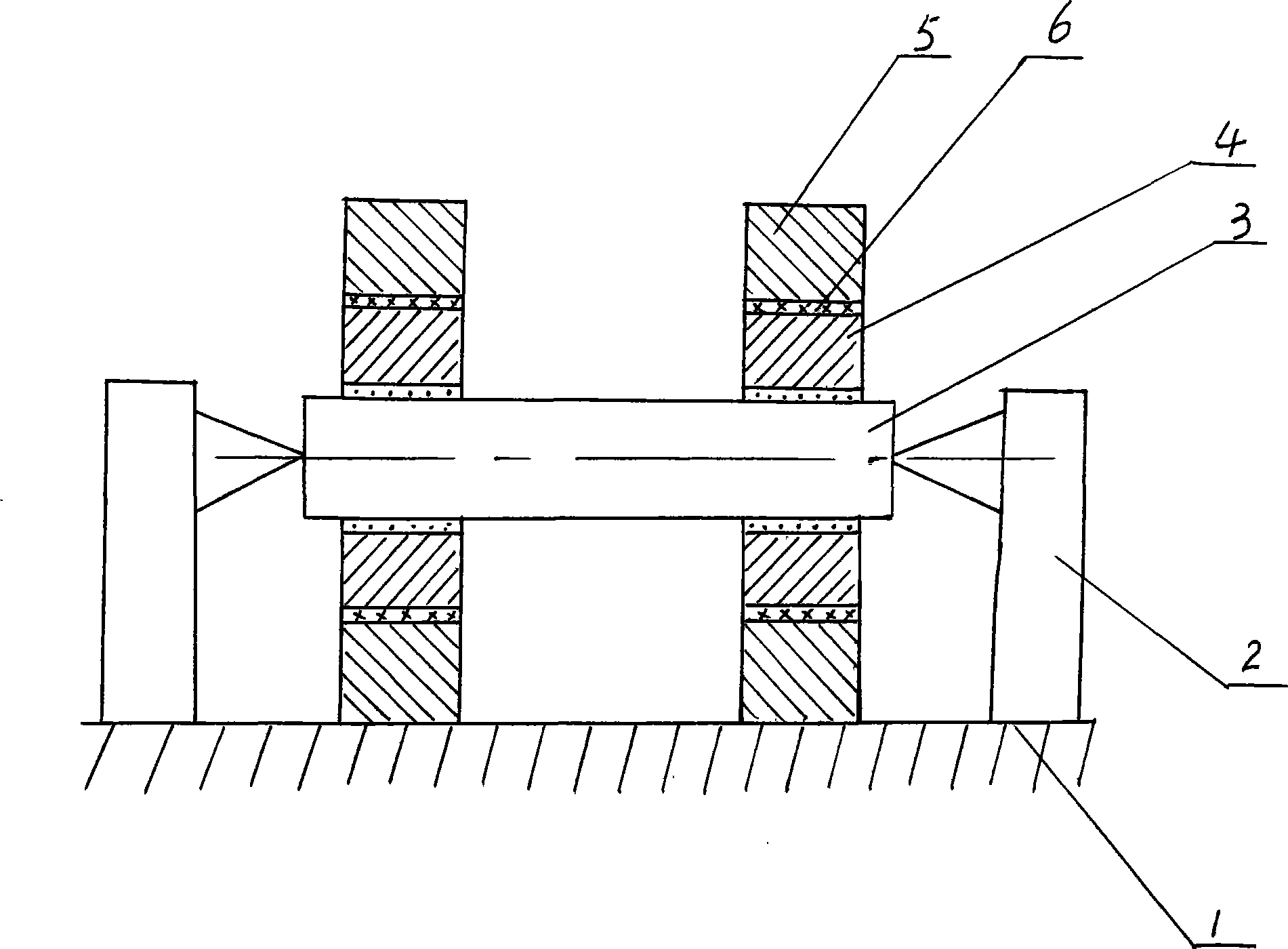

[0008] Such as figure 1 As shown, a dynamic and static pressure bearing assembly method is characterized in that:

[0009] A. Fix the bearing housing 5 on a base 1,

[0010] B. Support both ends of the shaft 3 with the shaft top 2, and the top 2 is also fixed on the base 1;

[0011] C. Process the inner rings 4 of the two bearings, put the two inner rings 4 between the shaft 3 and the housing 5, connect the oil circuit on the inner ring 4, and make the static pressure system between the inner ring 4 and the shaft 3 Work, the inner ring 4 floats on the shaft 3;

[0012] D. Enter the adhesive 6 in the gap between the shell 5 and the inner ring 4. After the adhesive 6 is cured, remove the shaft 3 and the shell 5 from the base 1, and the dynamic and static pressure bearing is completed. assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com