Straw crushing machine

A straw shredder and chassis technology, applied in agricultural machinery and implements, cutting equipment, applications, etc., can solve problems such as jamming of pulverizing knives and equipment failures, reduce the probability of jamming, improve work efficiency, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

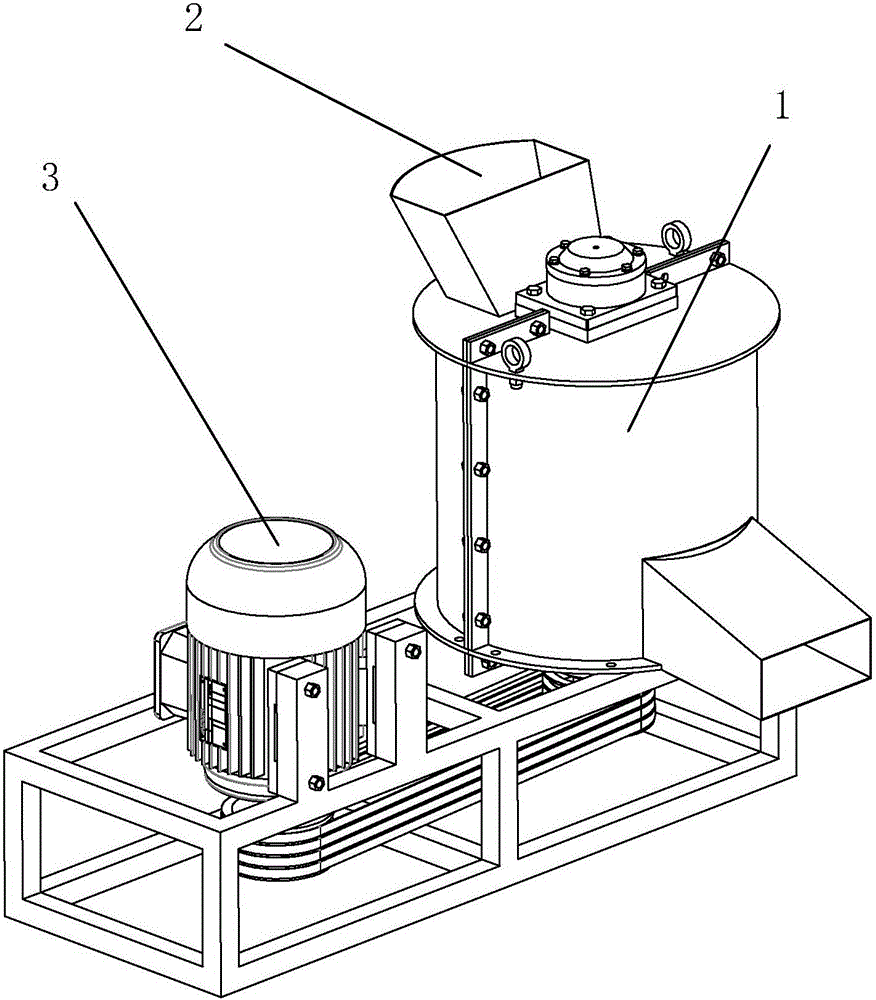

[0039] Embodiment one: if figure 1 As shown, a straw pulverizer includes a cylindrical case 1, and the upper end of the case 1 is a feed hopper 2, which is used for the entry of straw, and a rotating shaft 4 is arranged inside the case 1, and the two ends of the rotating shaft 4 are connected to the case by rotation. 1, one end of the rotating shaft 4 is connected to the motor 3 outside the chassis 1, and the power of the rotating shaft 4 is provided by the motor 3. The power of the device is 18.5 kilowatts, and the rotating speed of the motor 3 is 1440 rpm.

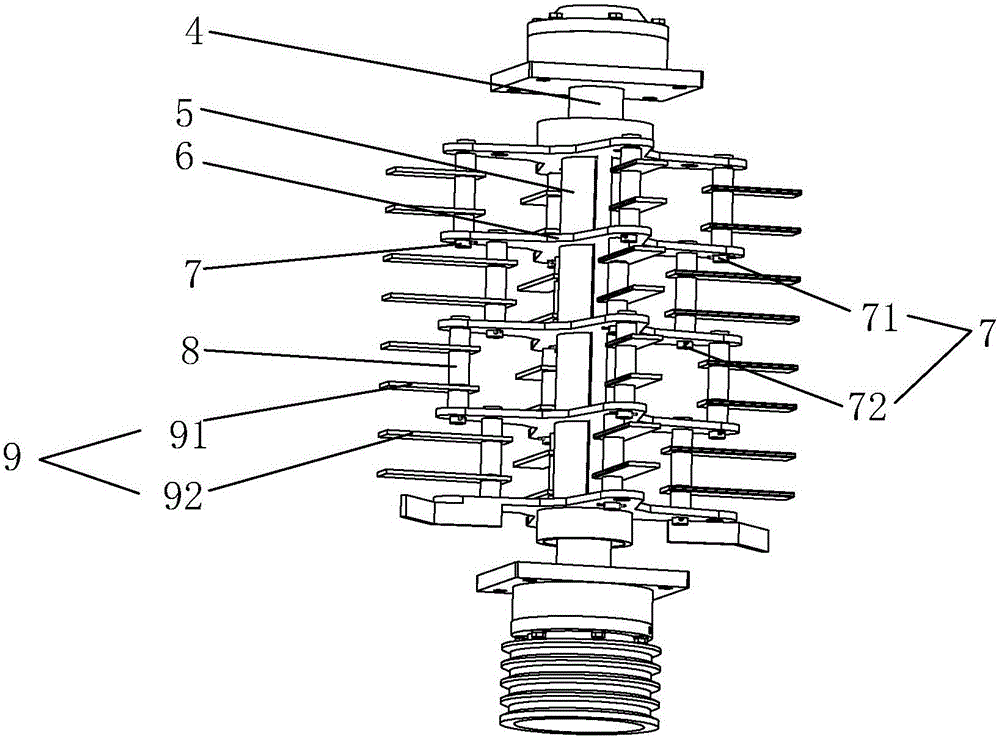

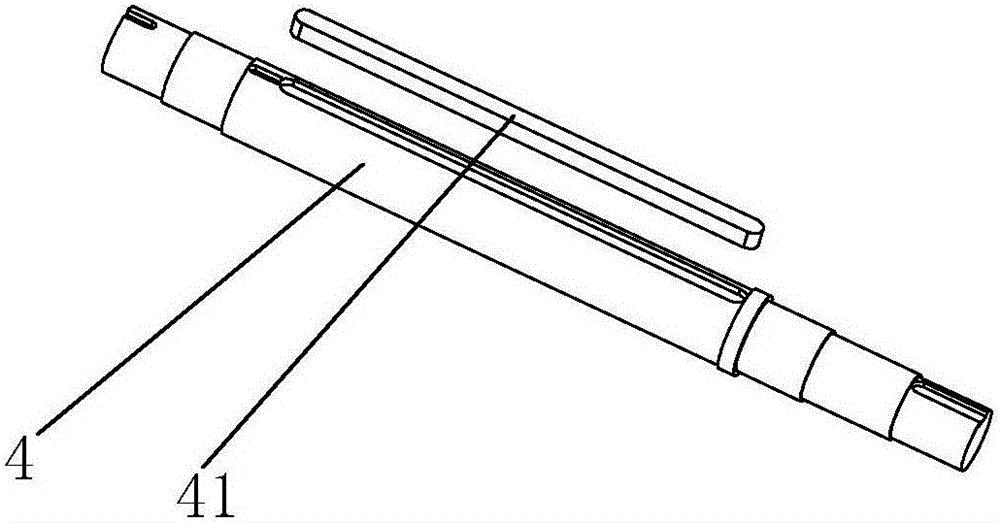

[0040] Such as figure 2 shown as well Figure 4 As shown, a plurality of first shaft sleeves 5 are sleeved on the shaft 4 along its axial direction, and a mounting plate 6 is arranged between adjacent first shaft sleeves 5, and the mounting plate 6 is sleeved on the shaft 4, The axial positioning of the mounting plate 6 is realized by the limitation of the first bushing 5 , and the mounting plate 6 cannot move in the ...

Embodiment 2

[0052] Embodiment two: if Figure 10 As shown, compared with the embodiment, the two ends of the connecting shaft 7 in this embodiment pass through the mounting hole 63 of the mounting seat 62. The part is a threaded rod, and the alignment of the connecting shaft 7 is realized by the cooperation of the positioning nut 12 and the threaded rod. When the straw is impacted and cut, the straw is not easily wound on the connecting shaft 7, and the connecting shaft 7 can rotate normally when receiving the force of the cutter 9, thereby improving the flexibility of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com