Electric motor, in particular for the windscreen wiper drive of a motor vehicle, with improved seating for the armature shaft bearing

A technology for electric motors, armature shafts, applied in the direction of shafts and bearings, rigid supports for bearing parts, bearing elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

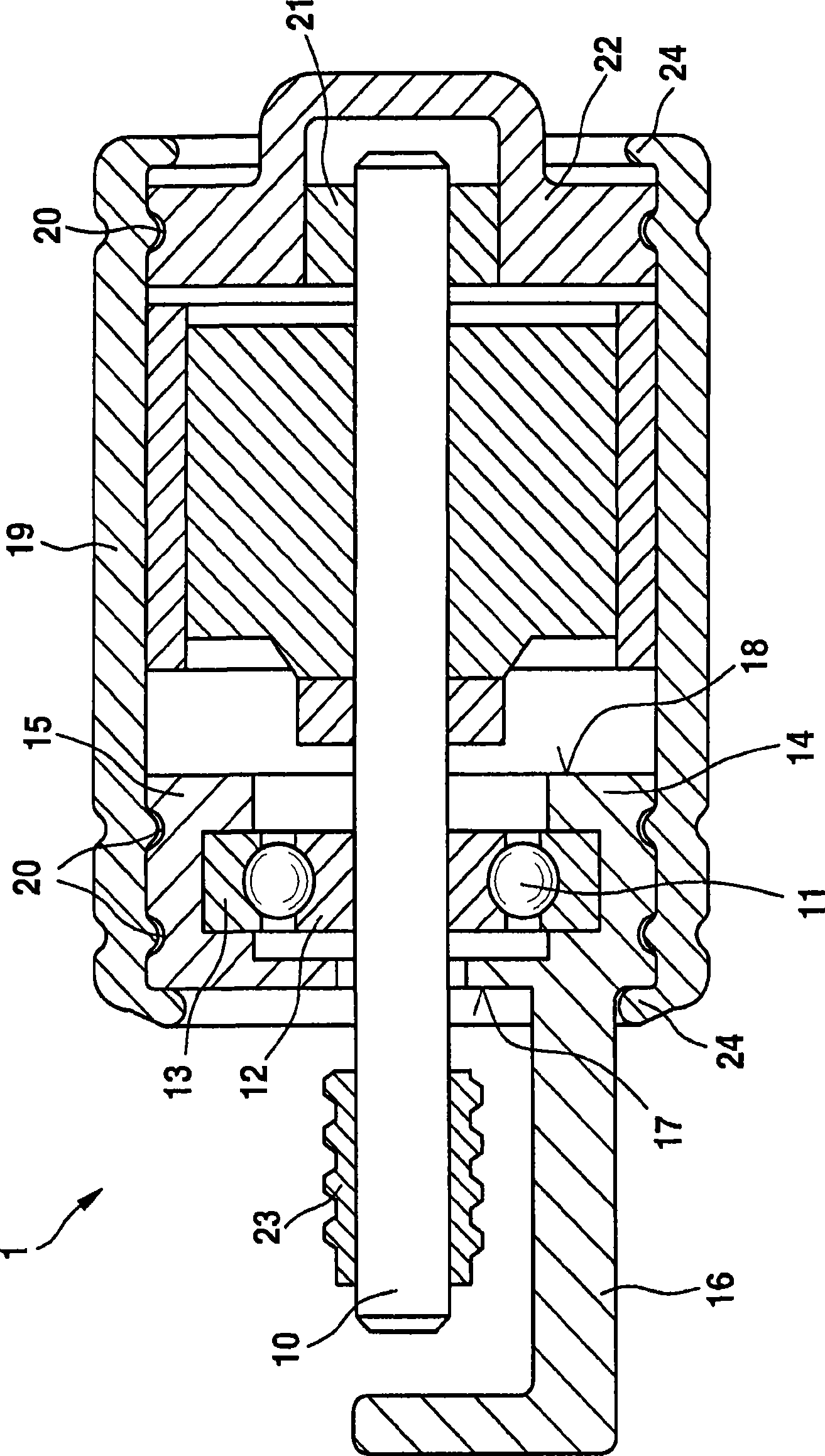

[0028] The electric motor 1 shown in the drawing consists of an armature shaft 10 , which is mounted rotatably within a pole housing 19 via a roller bearing 11 and a slide bearing 21 . The rolling bearing 11 consists of a bearing inner ring 12 and a bearing outer ring 13 in addition to the rolling elements. The bearing inner ring 12 is pressed against the armature shaft 10 or is fixed axially by fastening elements. The bearing outer ring 13 is located in a bearing seat, wherein the bearing seat itself is formed by a first half shell 14 and a second half shell 15 .

[0029] The half shells 14 and 15 each extend around the bearing outer ring 13 at an angle of 180°. A radially symmetrical bearing seat is produced by the first half shell 14 and the second half shell 15 , wherein the half shells 14 and 15 surround the rolling bearing 11 over the entire circumference. The first half shell 14 is formed by a section of the transmission housing 16 , so that the transmission housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com